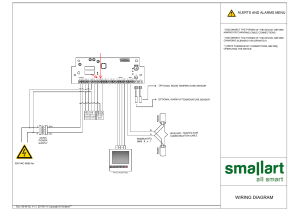

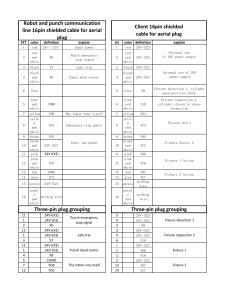

PIN 1 thru 9 are for digital inputs D101-D109. The common for this group of inputs is SDICOM1,

PIN 19. Therefore to connect a PNP sensor to any input within this group you would connect the

SDICOM1 (PIN 19) to 0vdc (PIN 17 or 18). Thus to connect a NPN to any input within this group

you would connect SDICOM1 (PIN 19) to +24vdc. You would then connect your sensor signal wire

to a digital input pin of your choice within the group and connect your 0 and 24vdc sensor wires.

For example, to connect your sensor to DI103, Connect the +24V sensor wire, typically brown, to PIN

49 or 50, and the sensor signal wire, typically black, to PIN 3. Connect the ground sensor wire,

typically blue, to PIN 17 or 18. Turn on your machine and on the TP navigate to digital I/O, select

Inputs, and go watch your sensor work.

PIN 9 thru 16 are for digital inputs D109-D116 and PIN 22-25 are for digital inputs D117-D120. I

have no idea why they broke this group up but notice the pins are not sequential. The common for this

whole group of inputs is SDICOM2, PIN 20. Therefore to connect a PNP sensor to any input within

this group you would connect the SDICCOM2 (PIN 20) to 0vdc (PIN 17 or 18). Thus to connect a

NPN you would connect SDICOM2 (PIN 20) to +24vdc. Connect your sensor as above

Remember the general rule with PLC’s or when interfacing sourcing and sinking devices is “Do the

opposite”. Meaning, if the sensor is PNP it connects to NPN and vice versa. In the above explanation

you can see that when we connect the common of the controller to a sink we use a PNP sensor and if

we source the common in the controller we need an NPN. Here we usually jump the 0vdc together and

do the same with +24vdc and also the SDICOM1 and SDICOM2 since we usually try to use all the

same type of sensor. Of course you can use both PNP and NPN sensors if you split your COM1 and

COM2.

I don’t know if your robot is on a CERT CART or not, but I connected all 50 wires into the connector

and then ran the other end of the cable out into the cell where I connected them to terminal blocks.

Now you can simply connect any sensors or outputs up in the terminal block. This allows very easy

connections without soldering every time you make a change or add something. It is also much easier

to test points when something does not work. Remember don’t go over about .2 amps draw. With the

terminal blocks it’s easy to connect micro relays and drive the coil with the robot outputs. Isolating

voltages between systems is always a good practice.

The robot will source the PLC's +24 back to it for all inputs. This means that you must

supply a +24vdc and 0vdc that is common to both the PLC input card as well as the

robot's output section. Technically, you can get +24 from somewhere else that is

separate from the PLC, but you still need the common 0vdc at minimum. The robot

output will not supply its own voltage to the output points.

Typically the robot outputs are optically isolated to prevent catastrophic damage from

occurring to the robot's computer if you were to accidentally connect 120vac to the

robot's IO.

You will need to supply output power if you are running more than a few LED’s or

something else very, very small. Fanuc factory connects their Banner 24V vision camera

directly to the connector when they ship it assembled but I do not know what that

draws. I use a Rino Din rail mounted power supply to supply power the robot outs and

the PLC. If you need to use separate power supplies for different voltages between

systems, use a small relay for the handshake. Using a relay you can also source or sink

the PLC module.

1

/

2

100%