TC148-2

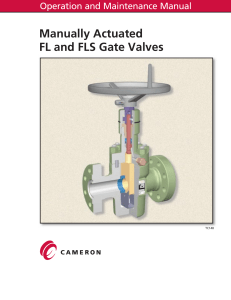

FL and FLS Gate Valve

Operation and Maintenance Manual

2

TC148-2

All information contained in this manual is the exclusive property of Cameron. Any repro-

duction or use of calculations, drawings, photographs, procedures or instructions, either

expressed or implied, is forbidden without written permission of Cameron or its authorized

agent.

Revision 07

December 2008

Revision 08

December 2009

Produced by Technical Publications, Houston, TX, USA

© 2009 Cameron

3

TC148-2

PREFACE

The procedures included in this book are to be performed in conjunction with the requirements

and recommendations outlined in API Specifications. Any repairs to the equipment covered by

this book should be done by an authorized Cameron service representative. Cameron will not

be responsible for loss or expense resulting from any failure of equipment or any damage to any

property or death or injury to any person resulting in whole or in part from repairs performed

by anyone other than authorized Cameron personnel. Such unauthorized repairs shall also serve

to terminate any contractual or other warranty, if any, on the equipment and may also result in

equipment no longer meeting applicable requirements.

File copies of this manual are maintained. Revisions and/or additions will be made as deemed

necessary by Cameron. The drawings in this book are not drawn to scale, but the dimensions

shown are accurate.

This book covers Cameron products.

Cameron

P.O. Box 1212

Houston, Texas 77251-1212

713-939-2211

http://www.c-a-m.com

4

TC148-2

GENERAL WARNING

READ AND UNDERSTAND ALL INSTRUCTIONS. Failure to follow may result in serious personal

injury and damage not only to equipment but also the environment.

1. Safety is a combination of staying alert, common sense, and experience with oil field equipment

and environment. Read this manual prior to operating and servicing the FL and FLS valve. Be

familiar with operation terminologies of gate valves and oil field equipment.

2. This document includes basic valve repair guidance. The field service personnel shall be fully

trained in all aspects of handling pressure control equipment as well as the job they are going

to perform on the FL and FLS valve models. If any procedures and policies listed in this document

cannot be followed, contact a Cameron Representative for best course of action.

3. Proper Personal Protective Equipment (PPE) shall be utilized according to Company policies.

Always use proper tools when servicing equipment.

4. A Job Hazard Analysis (JHA) must be performed prior to beginning service on a well location. A

JHA review meeting will be held with all affected rig personnel PRIOR to commencement of work

to review results of the JHA, evacuation routes, emergency contacts, etc. All meeting attendees

and a Company Representative will sign off on the JHA to acknowledge meeting has taken place.

5. Be aware of unexpected circumstances that may arise when operating or servicing valve. Utilize

Step Back 5X5 process in order to assess hazards posed before, during and after servicing of

equipment under pressure or with potential of hazardous chemicals present. Be familiar with

company’s and facility’s Lockout/Tagout program in order to ensure all sources of energy (i.e.

electrical, pneumatic, pressure) are isolated and/or de-energized prior to beginning work.

6. All governmental or Company safety requirements shall be met before working on valve.

Requirements of fully tested pressure barriers prior to servicing valve shall be observed.

Cameron recommends two mechanical pressure barriers is preferred practice. Lower Master

Valve (LMV) is a critical valve and additional precautions should be taken to ensure mechanical

pressure barriers are functioning correctly prior to work being carried out on this particular valve.

7. Always check for trapped pressure before servicing valve. All valves downstream of pressure

barriers must be cycled several times to release trapped pressure.

8. Ensure chemical and physical properties of fluid flow product inside valve are known. Obtain

applicable Material Safety Data Sheets (MSDS) for commonly encountered chemicals such

as hydrogen sulfide, cements, etc. in order to identify appropriate PPE to use, emergencies,

procedures, and methods or exposure control.

9. Always use correct lifting devices and follow safety rules in handling heavy products. The weight

of single cavity flanged and hub outlet valves are provided in this document for reference. Actual

valve weight can vary for valve block configurations. Never attempt to lift valve by hand. Do not

lift from handwheel or handwheel adapter. Valve should be lifted from valve body or end flange

outlets.

10. Cameron manufactures a variety of valve models with different features and operating

requirements. Be certain of valve model and refer to appropriate manual before attempting

operation or service on valve. This document is to assist field personnel in operation and

maintenance of the FL and FLS handwheel operated gate valve for valve sizes that are listed in

this document. Different documents are available for other FL/FLS valve sizes.

5

TC148-2

TABLE OF CONTENTS

1.0 SCOPE .........................................................................................................................6

2.0 GENERAL INFORMATION ..........................................................................................6

2.1 Description and Features ....................................................................................6

2.2 Parts List ...............................................................................................................8

2.3 Dimensional Data ................................................................................................9

3.0 VALVE OPERATION ....................................................................................................12

3.1 Open Valve ..........................................................................................................12

3.2 Close Valve ..........................................................................................................12

4.0 PERIODIC MAINTENANCE ..........................................................................................14

4.1 Valve Body Cavity Lubrication ............................................................................14

4.2 Stem Thrust Bearing Lubrication ........................................................................15

4.3 Lubricant Charts ...................................................................................................16

5.0 TROUBLESHOOTING ..................................................................................................17

6.0 BOLT TORQUE ............................................................................................................18

Recommended Makeup Torques Ft-lbf ....................................................................18

Recommended Makeup Torques N•m .....................................................................19

7.0 ORDERING REPLACEMENT PARTS ............................................................................20

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

1

/

20

100%