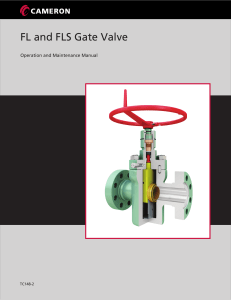

All the information contained in this manual is the exclusive property of

Cameron. Any reproduction or use of the calculations, drawings, photo-

graphs, procedures or instructions, either expressed or implied, is forbidden

without the written permission of Cameron or its authorized agent.

Initial Release A1

April 1992

Revision B1

April 1994

Revision C1

June, 1997

Copyright ©1997 all rights reserved

by

Cooper Cameron Corporation

Cameron Division

TC148 2

Rev C1 6/97

PREFACE

The procedures included in this book are to be performed in conjunction with

the requirements and recommendations outlined in API Specifications. Any

repairs to the equipment covered by this book should be done by an

authorized Cameron service representative. Cameron will not be responsible

for loss or expense resulting from any failure of equipment or any damage

to any property or injury or death to any person resulting in whole or in part

from repairs performed by other than authorized Cameron personnel. Such

unauthorized repairs shall also serve to terminate any contractual or other

warranty, if any, on the equipment and may also result in the equipment no

longer meeting applicable requirements.

File copies of this manual are maintained. Revisions and/or additions will be

made as deemed necessary by Cameron. The drawings in this book are not

drawn to scale, but the dimensions shown are accurate.

P.O. Box 1212

Houston, Texas 77251-1212

ph: 713-939-2211

http://www.coopercameron.com

TC148 3

Rev C1 6/97

CONTENTS

I. General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

A. Description and Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

B. Operation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

C. Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

D. Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

II. Periodic Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

A. Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

B. Lubrication Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

C. Body Cavity Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

D. Thrust Bearing Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

III. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

IV. Bonnet Grease Fitting Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

A. Valves 10,000 psi WP and Below . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

B. Valves 15,000 psi WP and Above. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

V. Stem Shear Pin and Thrust Bearing Replacement. . . . . . . . . . . . . . . . . . . . . . 17

A. Removal of the Thrust Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

B. Installation of the New Thrust Bearings. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

VI. Stem Packing Replacement with Pressure in the Valve. . . . . . . . . . . . . . . . . . 18

A. Removal of the Stem Packing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

B. Installation of the New Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

VII. Gate and Seat Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

A. Gate and Seat Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

B. Gate and Seat Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

C. Gate and Seat Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

VIII. Ordering Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

TC148 5

Rev C1 6/97

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

32

33

33

34

34

35

35

36

36

37

37

38

38

39

39

40

40

41

41

42

42

43

43

44

44

45

45

46

46

47

47

48

48

49

49

50

50

1

/

50

100%