Induction Motor Speed Control Using Sliding Mode Controller

Telechargé par

madenba641

52

Speed Controller of Three Phase Induction

Motor Using Sliding Mode Controller

Dr.Farazdaq R.Yaseen

1,Walaa H. Nasser2

1,2Control and System Eng. Dep.at Unversity of Technology

drfarazdq@gmail.com,walaahussain321@gmail.com

Abstract— A Sliding Mode Control (SMC) with integral surface is employed to control

the speed of Three-Phase Induction Motor in this paper. The strategy used is a modified

field oriented control to control the IM drive system. The SMC is used to calculate the

frequency required for generating three phase voltage of Space

v

Vector Pulse Width

Modulation (SVPWM) invertor. When the SMC is used with current controller, the

quadratic component of stator current is estimated by the controller. Instead of using

current controller, this paper proposed estimating the frequency of stator voltage

whereas the slip speed is representing a function of the quadratic current. The simulation

results of using the SMC showed that a good dynamic response can be obtained under

load disturbances as compared with the classical PI controller; the complete

mathematical model of the system is described and simulated in MATLAB/SIMULINK.

Index Terms—

Induction Motor, Space Vector Pulse Width Modulation, Sliding Mode Control

and Field Oriented Control.

I. INTRODUCTION

The three phase Induction Motors (IM) have earned a great interest in the recent years

and used widely in industrial applications such as robotics, paper and textile mills and

hybrid vehicles due to their low cost, high torque to size ratio, reliability, versatility,

ruggedness, high durability, and the ability to work in various environments. Some control

methods have been improved to adjust these IM drive systems in high-performance

applications [1]. The Field-Oriented Control (FOC) method can be considered as one of the

most popular techniques which is used to control the IM. Nowadays, the FOC strategy is

the most common method since it ensures the decoupling of the motor flux and torque, this

property of FOC gives an assurance that the IM drive sysytem can be controlled linearly as

a

a separately exited DC motor [1, 2, 3].

Conventional speed control of IM drives with a restricted gain such as PI controllers

did not provide an acceptable response for tracking the required trajectory. In order to

overcome the parameter variation and/or load changes obstacles, the variable structure

control strategy uses the SMC for controlling the AC drive because the SMC provides

many advantages, such as: good performance, robustness to the load disturbances, or

parameter variation, fast dynamic response, and simple implementation.

The SMC design requires two steps: The first step of this design is selecting the

suitable sliding surface S(t) in terms of tracking error while the second step is designing

control signal of the system u(t). Two types of the sliding surface can be recognized in the

sliding mode control, the first type is the conventional sliding surface and the other is the

integral sliding surface. In this work, an integral sliding surface is presented and its

interpretation is compared with the application of the conventional PI controller.

DOI: https://doi.org/10.33103/uot.ijccce.19.1.7

53

II. MATHEMATICAL MODEL OF THE THREE PHASE INDUCTION MOTOR

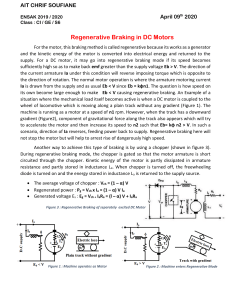

The equivalent circuit of IM in the stationary d-q reference frame is presented in

Fig.1. The IM dynamical model is given by [4].

DC

Vqs

Rs

LIs=Ls‐Lr Lir=Lr‐Lm Rr

Vqr

e e‐rr

qr

Lm

Iqr

Iqs

(

A

)

C

IRCUIT

DC

Vds

Rs

LIs=Ls‐Lr Lir=Lr‐Lm Rr

Vdr

e e‐rqr

dr

Lm

Idr

Ids

(

B

)

C

IRCUIT

F

IG

.

1.

IM

EQUIVALENT CIRCUIT A

)

CIRCUIT B

)

CIRCUIT

The stationary reference frame can be derived simply by substituting e=0. The

corresponding stationary frame equations are presented below:

Stator equations

λ

1

λ

2

Rotor equations

0

λ

λ

3

0

λ

λ

4

Where

=

=0.

Where represents the value of the flux linkage, V represents the voltage; R is the resistance, refer

to the value of the current and

represents the speed of the rotor. The subscript r denotes the

quantity of the rotor, s refers to the quantity of the stator, and the subscripts q and d are symbols for

the quadrature axis and direct axis components, respectively in the stationary reference frame.

The fluxes are combined with the currents according to the following expressions

5

6

7

8

54

Where

refers to the magnetizing inductance,

is the rotor inductance and

is the stator

inductance [1].

The equation of electromagnetic torque is given by:

3

2

2

9

Where p refers to the poles number of the motor. The mechanical dynamic equation which relates

the motor characteristic speed r to the torque is:

T

T

2

PJdω

dt 10

Where

and J refer to the load torque and the moment of inertia, respectively,

refer to the slip

frequency and

and it can be obtained as:

ω

L

R

Ψ

L

11

The dynamic model of the IM can be expressed in Fig 2.

F

IG

.2

T

HE

D

YNAMIC MODEL OF

IM.

III. SPACE VECTOR PLUSE WIDTH MODULATION INVERTER

This inverter consists of three legs with 6 controlled swithches (S1 to S6). The idea is

generation of a vector with amplitude Vref which moves with an angle () across 6 sectors

shown in Fig.3 . The SVPWM can be performed in the following three steps:

Step 1. Calculation of Vref and angle () from Vd and Vq

Step 2. Calculation of the time duration T1, T2 , and T0

Step 3. Calculation of the switching time of every switching device (S1 to S6) [5].

55

F

IG

3.

T

HE

B

ASIC SWITCHING VECTORS AND SECTORS

.

F

IG

.4

M

ODEL OF

SVPWM.

IV. PI CONTROLLER

The conventional Proportional plus Integral controller (PI) is a simple speed controller in

industrial applications. Under the load condition, the PI controllers try to modify the motor speed to

attain the desired system speed. The output of the PI controller is a function of the speed error and the

integral of error [6]:

12

56

F

IG

.5

T

HE BLOCK DIAGRAM OF CONVENTIONAL

PI

CONTROLLER

.

V. SLIDING MODE CONTROLLER

The overall block diagram of the IM using (SMC) speed control system is shown in Fig.6, where

the quantity of the actual speed (

) generated by the IM is compared to the desired value

∗

) to

produce an error signal ().

This error signal and its derivative () are fed to the SMC, which generates a slip frequency and

estimates the required frequency for SVPWM where this value is the input to the VSI.

These inputs are used by the VSI for generating a three phase voltage whereas the variation of

amplitude and the frequency is done by the SMC.

Generally, the mechanical equation of an IM can be presented as follows [7, 8]:

13

Where B is the friction factor of the IM,

refers to the external applied load ,

refer to the

mechanical speed of the rotor, while

is a point to the electromagnetic torque which can be

represented in Eq. (9) as:

3

2

2

9

According to the FOC principle, the ccurrent component

is lined up the direction of the rotor

flux vector

and the current vector

is lined up perpendicular to it, so the flux vector

|

|, and Eq.(9) becomes:

3

2

2

14

Where

denotes the constant of the torque, and it can be defined as follows:

3

2

2

15

Using Eq. (14) into (13) then we can get

bi

ω

aω

f16

Where

,

and

Eq. (16) can be presented with uncertainties ∆ ,∆ and∆, as follow:

∆

∆ ∆

17

The error of the tracking speed can be define as

∗

18

Where

∗

is a point to reference speed of the rotor, then by taking the derivative of the

pervious equation with respect to time it produces:

6

6

7

7

8

8

9

9

10

10

11

11

1

/

11

100%