Caterpillar Robot Motion: Bionic Patterns & Sinusoidal Control

Telechargé par

meryasm13

Research Article

Analysis and Implementation of Multiple Bionic Motion

Patterns for Caterpillar Robot Driven by Sinusoidal Oscillator

Yanhe Zhu, Xiaolu Wang, Jizhuang Fan, Sajid Iqbal, Dongyang Bie, and Jie Zhao

State Key Laboratory of Robotics and System, Harbin Institute of Technology, Harbin 150000, China

Correspondence should be addressed to Jizhuang Fan; fanjizhuang@hit.edu.cn

Received February ; Accepted April ; Published May

Academic Editor: Yong Tao

Copyright © Yanhe Zhu et al. is is an open access article distributed under the Creative Commons Attribution License,

which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Articulated caterpillar robot has various locomotion patterns—which make it adaptable to dierent tasks. Generally, the researchers

have realized undulatory (transverse wave) and simple rolling locomotion. But many motion patterns are still unexplored. In this

paper, peristaltic locomotion and various additional rolling patterns are achieved by employing sinusoidal oscillator with xed

phase dierence as the joint controller. e usefulness of the proposed method is veried using simulation and experiment. e

design parameters for dierent locomotion patterns have been calculated that they can be replicated in similar robots immediately.

1. Introduction

e Almighty God created many chain-type creatures such as

caterpillar, snake, and earthworm. By utilizing their inherent

special structure, they can adapt to various environments

through multiple locomotion patterns [,]. For instance, a

caterpillar can move in transverse-wave motion to run fast or

peristaltic motion to sneak through a narrow hole.

e robotics community has been trying to make arti-

facts to exploit the movement mechanism of these versatile

animals. Many specially designed caterpillar robots have

been realized. Besides, the modular self-recongurable robot

(MSRR) composed of many building blocks can be used to

construct diverse types of robots, including caterpillar robot.

Several architectural groups are classied according to the

geometrical arrangement of MSRR units: chain-type, lattice-

type, and hybrid-type [,]. Chain-type and hybrid-type

robot ts for application of coordinated locomotion.

Transverse-wave locomotion is realized on many articu-

lated chain-type caterpillar robots, as in [–]. In these stud-

ies, dierent kinds of transverse-wave forms are employed,

including sine-based wave. But peristaltic motion is not real-

ized on articulated caterpillar robots. Only robots utilizing

special material like SMA (shape memory alloy) or special

structure that mimic the stretch characteristics of caterpillar

and earthworm [–] realize this motion pattern. Besides,

many implemented rolling motions based on chain-type

robot are hand-planned [] and lack generality.

Transverse-wave and peristaltic motion can adapt to

dierent environments, but to the best of our knowledge

no researcher has yet achieved both two motion patterns in

articulated chain-type robot. In this paper, simple sinusoidal

oscillator with xed phase dierence is employed as the

joint controller for achieving transverse-wave and peristaltic

motion. Additionally, multipattern rolling motion like ellipse,

triangle, and other polygon rolling is planned using the same

controller. Figure illustrates some motion patterns suggested

in this paper. Motion patterns from top down are transverse-

wave motion similar to caterpillar and millipede; peristaltic

motion like earthworm; and various rolling patterns beyond

the capability of animals like armadillo.

is paper is organized as follows: Section introduces

the caterpillar robot model and its simple controller. Section

presents the details of unied planning method for many

bionic motion patterns. e experimental results are shared

in Section . Discussion and future work are presented in

Section . Finally Section concludes the paper.

2. Caterpillar Robot and Simulator

2.1. Caterpillar Robot. Caterpillar robot, also known as

“worm-robot” or “snake-robot,” is an articulated chain-type

Hindawi Publishing Corporation

Advances in Mechanical Engineering

Volume 2014, Article ID 259463, 12 pages

http://dx.doi.org/10.1155/2014/259463

Advances in Mechanical Engineering

F : Multipattern locomotion examples.

12 in

X

Y

P00

P10

J10

J00

Z

i+1 n−1

······

··· ···

F : Kinematics model of UBot module and topology of composed caterpillar robot.

robot. Its joint axes are perpendicular to its motion direction

and parallel to ground. Our investigated caterpillar robot is

composed of UBot modules [,], which are hybrid-type

MSRR. Figure shows kinematics model of UBot module

and caterpillar robot. Each UBot module has two rotary

degrees of freedom. Each joint can rotate ranging from −∘

to ∘.Forcaterpillarrobot,eachmoduleusesonlyone

joint perpendicular to body line from head to tail. It can be

recognized as a planar linkage mechanism for analyzing its

kinematics.

2.2. Controller. Sine-based controller, model-based con-

troller, and CPG (central pattern generation) are oen

employed to generate rhythmic locomotion for robots.

Model-based controller relies on careful analysis and is oen

piecewise function to keep motion shape. Corresponding

model should be carefully designed for certain motion

patterns. Examples like triangular wave and trapezoidal

wavecanbeseenin[,]. CPG-based controller is very

useful for smoothing gaits transition which depends on

communication between modules. If just using CPG-signal

without communication coordination, we do not see any

advantage in controlling modular robot compared with sine-

based controller.

Sine-based controller is easy to implement and can mimic

lots of rhythmic motion patterns. In this paper, sine-based

controller with certain phase-lag is used on each module; see

(). Oset, amplitude, and phase dierence are the same for

all the modules. us only three design parameters need to

be designed: Oset, ,and. Consider

𝑖()=Oset +∗sin +∗ ,

Oset ∈−90

∘,90∘,

Advances in Mechanical Engineering

Parameters

set panel

F : UBotsim—D dynamics simulator.

∈0,90

∘−|Oset|,

∈ [0,],

()

where is module ID and ID increases from head to tail.

Oset is oscillatory center of joint angle. is signal amplitude

relative to Oset. is the phase dierence (or phase-

lag) between adjacent modules. us joint signals are the

same with an identical phase dierence. A variety of novel

motionpatternscanbeachievedbymanipulatingthethree

parameters.

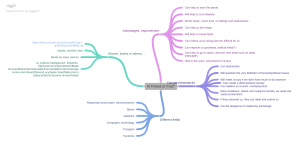

2.3. UBotsim Simulator. To quickly verify the eectiveness

of the proposed strategy, a dynamics simulator is required.

Many leading MSRR researchers have developed their own

simulator to customize the analysis and evaluation. A newly

developed D dynamics simulator UBotsim is used to test

the method. It is based on PhysX engine and OGRE (object

oriented graphics rendering engine). Figure shows a screen-

shot of UBotsim. A parameter panel is designed to tune

planning parameters, which is strictly related to the joint

controller ().

3. Planning of Multiple Bionic

Motion Patterns

3.1. Wave Patterns. In wave motions patterns, drive signal

vibrates at the joint osetwhich is always set as ∘.

3.1.1. Undulatory Motion Like Transverse Wave. In this pat-

tern,robotshapelookslikeasinecurveduringmotion

procedure(asshowninFigures(a),(b),and(c)). e

phase dierence is determined by the number of modules

in a complete waveform. Suppose there are modules in a

waveform(herecountmodulesonheadandtailofacomplete

waveformas;belowisthesame);theequationcanbe

achieved as = 2/(−1).Inotherwords,determines

thenumberofmodulesinasine-waveform.Ifis identical,

the greater the amplitude is, the higher the waveform height

will be.

Figure (d) shows module has displacements both in

horizontal and vertical directions. When right grounding

module is replaced by another module, the robot moves a

distance of .ereare−1replacement processes in a

period of time . Consequently, when is the same, the

higher the waveform is, the faster the robot runs. Here the

robot speed can be written as

V= ((−1)∗ )/. Generally

the greater the amplitude is, the higher the speed is.

e waveform resembles a sine curve if is big. But

considering the geometry and load capacity of actual module,

thereshouldbelessthantenmodulesinacompletewaveform

(it varies for dierent robot). To make the replacement of

grounding modules successful, there should be more than

four modules in a full waveform.

According to the above analysis, motion planning

method for caterpillar robot in sine-waveform can be set as

𝑖()=Oset +∗sin +∗ ,

Oset =0

∘,

∈0,90

∘,

= 2

−1,≥4.

()

Two types of sine-wave locomotion when takes

dierent values are discussed below.

Caterpillar-Like Locomotion. is locomotion has obvious

arches. To simulate a caterpillar, there should be certain

number of modules in a full-waveform. In this pattern,

the emergence of crest and trough is inevitable. Figure

illustrates the simulation screenshot that a caterpillar robot

composed of modules moves in transverse wave. e

shape of the robot looks like the caterpillar. e parameters

are set as =30

∘and = /4(=9).

Millipede-Like Locomotion. If =4( = 2/3), the

number of modules in a complete waveform is fewest. In

this situation, waveform does not resemble the sine curve.

e number of grounding modules is at its maximum. Robot

movement looks like a millipede. As it is unable to shape

ahigharch,amplitudecan be set to the maximum to

increase motion speed. Figure is a simulation screenshot of

millipede-like locomotion when =90

∘.

As the amplitude increases, waveform height will also

increase.ismayleadtocollisionbetweenmodules.An

instance for =80

∘canbeseeninFigure.Aquestionis

whatthebiggestvalueofis for specic .Innumerical

simulation of kinematics, if any distance between module

centers at time is less than the threshold 1.414∗Module-

Length, corresponding is recognized as the biggest ampli-

tude for corresponding . is condition guarantees that

collision would not happen throughout motion procedure.

To make the motion process stable, the ratio between

wave-height and wave-length should be small, as shown

in Figure . If the ratio is too small, robot locomotion is not

ecient and robot moves slowly. Combining stability and

speed, amplitudes located in

0.2 ≤ ratio =

≤ 0.6 ()

are set as preferred amplitudes scope.

Advances in Mechanical Engineering

1t=t

0

𝜃(𝜙)

−A

A

𝜙

𝜆

Δ𝜙

(a)

2t=t

0+T/12

𝜃(𝜙)

−A

A

Δ𝜙

𝜙

𝜆

(b)

𝜃(𝜙)

Δ𝜙

−A

A

3t=t

0+T/6

𝜙

𝜆

(c)

Motion

direction

s

3

1

2

(d)

F : Locomotion mechanism of caterpillar robot in sine-waveform.

F : Caterpillar-like locomotion of -module robot.

F : Millipede-like locomotion of -module robot.

e biggest and preferred amplitudes are calculated using

numerical simulation. is is implemented in MATLAB as

follows. Firstly, set the metrics of corresponding biggest and

preferred amplitudes. en set coordinates of module ID

as (, ) and compute each module’s coordinate in time

Distance between

module centers

F : Collision example.

(∈[0,]). According to the coordinates information,

we can calculate whether corresponding amplitude fullls

the metrics condition. Here evaluated amplitude values are

integers from ∘to ∘for the sake of reducing computation

time.

Advances in Mechanical Engineering

h

𝜆

F : Waveform parameters.

Figure illustrates the results; red line is the biggest

amplitude. Other lines represent biggest amplitude when

ratio is less than a specic number. Combining the design

formula (), this can be a reference graph for planning sine-

wave locomotion for series of caterpillar robot.

3.1.2. Peristaltic Motion Like Longitudinal Wave. If = ,

the robot just expands and contracts its body because joint

angles of adjacent modules are opposite. e robot expands

its body when all joint angles are ∘and contracts its body

when all joints are at amplitude (±). But the whole body

cannot move.

If 2/3 < < , segment of adjacent modules

can also expand and contract because adjacent module

angles are approximately opposite. Meanwhile there are

both expanding and contracting segments across the whole

body. As time passes, expanding segment and contracting

segment swap states to make robot move like a longitudinal

wave.

Figure shows joint angle and robot shape states at

two time instants when = 11/12,=90

∘.When

=

0,theneighborhoodsegmentofjointangleequalto

∘(blue area) is in expanding state, and center distance of

adjacent modules projected in motion direction is large and

shapesthesparsepartoflongitudinalwave.eareaofjoint

angle equal to −∘(red area) is in contracting state, center

distance of adjacent modules projected in motion direction

is small, and this segment shapes dense part of longitudinal

wave. When =

0+ /4, joint of ∘rotates to ∘and joint

−∘to ∘; expanding and contracting states switch. Dense

part is useful for support robot and sparse part for transfer

modules. is is a little analogous to the peristaltic motion of

earthworm.

e module whose joint angle is at ± is the center

ofdensepartandthemodulewhosejointangleisat

∘

is the center of sparse part. In a period of ,amodule

can be the center of dense and sparse part twice. Modules

between adjacent dense (or sparse) centers create a complete

longitudinal waveform. e phase dierence of two adjacent

4 5 6 7 8 9 10

20

30

40

50

60

70

80

90

Number of modules in a complete wave

Amplitude (deg)

Biggest amplitude

Ratio ≤ 0.6

Ratio ≤ 0.5

Ratio ≤ 0.4

Ratio ≤ 0.3

Ratio ≤ 0.2

F : Amplitude design reference in sine-waveform motion.

dense (or sparse) centers is .Supposetherearemodules in

a complete waveform. is is accumulated by −1controller

deviation of from ;thatis,( − 1) ∗ ( − ) = .

Consequently, peristaltic motion design formula is achieved

as

𝑖()=Oset +∗sin +∗ ,

Oset =0

∘,

∈0,90

∘,

= −

−1,>4.

()

e larger the amplitude is, the denser the contracting

part will be. Owing to the wave height is small, amplitude

couldhaveabiggervaluewithoutconcerningaboutmodule

collision. To make a robot move in complete waveform,

should be less than the robot module number. When is

larger than , the longitudinal eect becomes apparent.

Earthworm-Like Locomotion. An earthworm can move for-

ward by stretching its special body structure, as shown in

Figure (a) []. Using above method, this type of locomotion

can be simulated in articulated chain-type robot, as shown in

Figure (b). e simulation screenshots are a half-motion

when =90

∘and = 11/12. It can be seen that the robot

moves by alternately exchanging dense part and sparse part

just like the earthworm.

3.2. Closed-Loop Rolling. Technical artifacts can surpass

locomotion abilities of natural creatures; for example, a

caterpillar robot can roll in a loop. e caterpillar robot

composed of UBot MSRR modules can form a loop by

connecting head and tail module. More than ve modules

are needed to make a loop suitable for motion. In a rolling

loop, the sum of exterior angles must be ∘.Figure

illustrates the exterior angles of a polygon. Joint angle shapes

the exterior angle.

6

6

7

7

8

8

9

9

10

10

11

11

12

12

1

/

12

100%

![[www.georgejpappas.org]](http://s1.studylibfr.com/store/data/009043706_1-8c3453392420c0c6231055ee19191cac-300x300.png)