DATE:

Formal

Risk

Assessment

and

Job

Safety

Analysis

Plant and Department: U&O

Project Title: To install C20+ truck loading facility in united U&O

Activity/Task

Title:

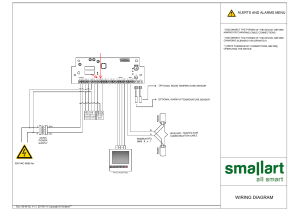

Electrical

and

Instrunmentation

work

(Cable

Pulling,

Terminations,

Piping

Modification,Cable

tray

work,Support

welding

)

Job Steps & Sub Tasks

1

Mobilization

(Cable

Materials,

cable

drum

and

Equipment’s

by

using

crane,focklift,boom

truck

&

dump

truck)

2

Lifting

and

positining

of

Cable

drum

&

cable

stand.

3

Cable

Meggering

and

Instrument

loop

checking.

4

Installation

of

new

breaker

in

substation

&

Cable

termination

and

Card

installation,DCS

Configuration

in

RIB.

5

Cable

Pulling.

6

Termination of power & control cables in control panels & JB’s and in RIB.

7

Dismantling

&

removal

of

existing

Panels

JB’s

and

conduits

&

installation

of

new

JB's,transformers

and

heat

tracing

equipments.

8

Installing

cable

Trays/conduits

&

Tubes,

threading

and

bending,

Drilling

and

knock

out.

9

Support

welding

activity

10

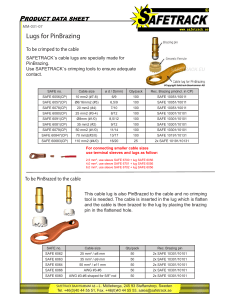

Cable splicing, cad welding, Heat shrinking by Heat gun or gas torch.

11

Cable

lugging

and

termination.

Job steps s#

HAZARD

Initial/raw

risk

Control

measures

Residual

Risk

Responsibility

Consequences

Likelihood

Risk

Consequences

Likelihood

Risk

Responsible

person

1. Mobilization (Cable Materials,

cable drum and Equipment’s by

using

crane,focklift,boom

truck

&

drum

truck)

1. Un-inspected, uncertified rigging tools

and tackles Crane / incompetent

personnel that could lead to personal

injury.

C4

L3

Minor

1.

Obtain

valid

work

permit

and

vehicle

entry

certificate

for

the

task.

2.

Ensure that Crane,Forklift & truck must be inspected by UNITED mobile equipment &

must have a valid inspection sticker.

3.

Only UNITED authorized crane & forklift operator, riggers, flag man (rigger) are

allowed to perform their job.

4.

All lifting tools and tackles should be inspected and current color coded by UNITED

mobile equipment.

C4

L4

Insignificant

HKSS/UNITED

2.Damage to the vehicles, plant facilities

and equipment.

C3

L3

Significant

1.

Ensure to comply with SHEM-08.06 lifting procedure. Enroute area shall be inspected

prior to mobilizing (unsafe ground condition).

2.

Ensure to obtain a vehicle entry certificate, approved basic/critical lifting certificate

(SHEM 08.06) and work permit for crane lifting ,Boom truck & forklift activity prior to

entry into the job site.

3.

Ensure

proper

distance

between

equipment

(congested

area,

other

activities).

4.

Follow the UNITED traffic rules and regulations.

5.

Follow

equipment

route

map

as

per

vehicle

movement

certificate.

6.

Conduct gas test to ensure 0% LEL.

C3

L4

Minor

HKSS/UNITED

3. Heat coming from Internal

combustible engine that could cause fire.

C3

L3

Significant

1.

Gas test shall be conducted to ensure 0% LEL.

2.

Combustible/flammable

materials

should

be

removed

from

the

area.

3.

While refueling vehicle engine should be shut down, no Hot work activity shall be

allowed nearby area.

4.

Cover all sewer lines by using fire blanket on the radius of 3 meters.

5.

Fire

extinguisher

should

be

placed

near

the

crane.

6.

Grounding

cable

should

be

connected

at

proper

grounding

point.

C3

L4

Minor

HKSS/UNITED

1. Fall of suspended load that could lead

to

property

damage

and

personal

injury.

C3

L3

Significant

1.

Lifting area should be barricaded with proper sign board. No personnel are allowed

to walk, stand or work under suspended load. Rigging Supervisor shall conduct tool box

talk to workers and explain jsa/work permit.

2.

Rigger

should

be

visible

to

the

crane

operator/enough

riggers

should

be

provided.

3.

Lifting tools and tackles shall be verified by authorized rigger. Softners shall be

provided for slings wound around sharp edges.

4.

Only authorized person by riggers shall be allowed to enter inside the barricaded

area.

5.

Lifting

shall

be

performed

as

per

approved

lifting

certificate.

6.

Proper

planning

and

supervision

by

related

supervisor

at

all

the

time.

C3

L4

Minor

HKSS

2. Lifting and positining of Cable

drum & cable stand.

2. High wind speed/ bad weather

conditions that could cause property

damage

and

personal

injury.

C3

L3

Significant

1.

Avoid

lifting

during

wind

speed

>32Km/hr.

2.

Avoid lifting during bad weather conditions (Rain/Fog/dust storm). Provide adequate

lighting for night time. Ensure lights not reflecting eyes of rigger / crane operator.

C3

L4

Minor

HKSS

3. Congested area and pinch point that

can

cause

personal

injury/slip,trip

and

fall

C4

L3

Minor

1.

Always wear PPE ( hand gloves, goggles) at all times while doing rigging.

2.

Keep away your hand from pinch point.

3.

Rigger

should

always

stand

to

safe

side

where

the

crane

operator

can

directly

see.

C4

L4

Insignificant

HKSS

4.Swinging load / Hitting rigger/Assets /

equipments/facility.

C3

L3

Significant

1.

Rigger shall not stay in line of fire or shall come under suspended load. Use tag lines

to control movement of load.

2.

The rigger shall ensure the load is rigged properly consider the centre of gravity and

use tag lines to control unexpected movement of load.

3.

Rigger shall stay away from line of fire.

C3

L4

Minor

HKSS

3. Cable Meggering and Instrument

loop checking.

1.

Electrical

Shock

C4

L3

Minor

1.

Obtain valid permkit for the task.

2.

Barricade

area,

place

wiith

warning

signs.

3.

Use insulated tools. Make sure free end of cable is insulated to ensure no one

touches it.

4.

Discharge

current

after

test,

confirm

with

multimeter.

5.

Use

of

calibrated

multimeter

&

hart

communicater

for

loop

check.

C4

L4

Insignificant

HKSS/UNITED

2.

Cuts,

personal

injury.

C4

L3

Minor

1.

Use

proper

PPE,

insulated

low

voltage

eltectrical

gloves

shall

be

used.

C4

L4

Insignificant

HKSS

4. Installation of new breakers in

substation

&

Cable

termination,

Card installation,DCS Configuration

in RIB.

1.

Wrong

installation

of

breakers.

C4

L3

Minor

1.

Obtain valid and proper work permit for the task.

2.

Only

allow

competent

electrician/person

for

the

task.

3.

All the cable termination and breaker installation by the presence of UNITED

authorised person.

4.

Make

sure

the

breakers

are

installing

asper

the

drawing.

5.

All

the

RIB

configuration

shall

be

done

by

authorized

person.

C4

L4

Insignificant

HKSS/UNITED

2.

Electrocution

&

Pinch

point.

C4

L3

Minor

1.

Use of proper PPE ( low voltage electrical gloves).

2.

Keep your hands away from pinch points.

3.

Make sure all the tools should be insulated.

4.

Secure tools and nut bolts properly to prevent fall or contact with live systems.

C4

L4

Insignificant

HKSS

3.Slip,Trip,Fall.

C4

L3

Minor

1.

Maintain

good

housekeeping

all

the

time

and

watch

your

steps.

C4

L3

Insignificant

HKSS

5. Cable Pulling.

1.

Falling

cable

drum.

C4

L3

Minor

1.

Place cable drum on level ground.

2.

Apply

proper

lubricant

on

rotating

point

of

drum

for

smooth

running.

3.

Barricade

work

area

place

warning

signs.

C4

L4

Insignificant

HKSS

2. Personnel injury,ergonomical

hazards,heat stress.

C4

L3

Minor

1. Use leather gloves Give enough rest breaks to workers , provide cool drinking water

and juice to workers.Do not strain back muscles.

C4

L4

Insignificant

HKSS

3.

Falling

from

heights

(Personnel

,cable

)

C4

L3

Minor

1.

Use full body harness, If needed to extend body part out of handrails or unprotected

edges with scaffolding tag yellow.

2.

Ensure scaffolding having valid inspection tag. ( If scaffolding is tagged green,Full

body harness is not required).

3.

Always

maintain

three

point

contact.

C4

L4

Insignificant

HKSS

4.

Damage

to

insulation

cable.

C4

L3

Minor

1.

Use roller for pulling cables to prevent damage.

2.

Ensure

cables

don’t

strike

scaffolding

parts

while

pulling.

C4

L4

Insignificant

HKSS

6. Termination of power & control

cables in control panels & JB’s, and

in RIB.

1. Electric shock

C3

L3

Significant

1.

Confirm

LOTO,

Confirm

panels

and

MCC’s

are

grounded.

Use

multimeters

to

Check

for

current.

Use

insulated

tools.

2.

Do not carry or wear any metal objects such as rings, watches, chains etc.

3.

Confirm

panels

&

JB’s

are

grounded

before

beginning

work.

4.

Make

sure

multimeters

are

calibrated.

C3

L4

Minor

HKSS/UNITED

2. Personnel injury & ergonomical

hazards

C4

L3

Minor

1.

Use

safety

goggles,electrical

gloves.

2.

Avoid

awkward

movements.

C4

L4

Insignificant

HKSS

3. Slips, trips, & falls.

C4

L3

Minor

1.

Keep

walkways

clear

of

tools

and

cables.

Post

warning

signs,Barricade

area.

C4

L4

Insignificant

HKSS

7.

Dismantling

&

removal

of

existing Panels JB’s and conduits &

installation of

newJB's,transformers and heat

tracing equipments.

1. Wrong Panel & Conduits removals

C4

L3

Minor

1. Make sure, double check and reconfirm from site engineer and mark the panels and

conduits to be removed.

C4

L4

Insignificant

HKSS

2.

Personal

injury

C4

L3

Minor

1.

Use

leather

gloves,

proper

PPE.

2.

Use proper tools for the job & Inspect tools for damage before use.

C4

L4

Insignificant

HKSS

3. Damage to plant property & assets.

C4

L3

Minor

1.

Make sure of shape, weight and size of new JB’s and panels & Conduits before

installation.

2.

Use

proper

lifting

and

handling

techniques

to

avoid

damage

to

equipment.

C4

L4

Insignificant

HKSS

8. Installing cable Trays/conduits &

Tubes, conduit threading &

Bending,

Drilling

and

knock

out.

1. Working at heights

Falling

from

heights.

C4

L3

Minor

1.

Use full body harness, If needed to extend body part out of handrails or unprotected

edges with scaffolding tag yellow.

2.

Ensure scaffolding having valid inspection tag. ( If scaffolding is tagged green,Full

body harness is not required).

3.

Always

maintain

three

point

contact.

while

ascending

or

descending

ladder.

C4

L4

Insignificant

HKSS

2. Dropping tools and

Materials.

C4

L3

Minor

1.

Ensure scaffolding plat form is free from tools and materials. make sure toe boards

are installed on scaffolding.

2.

Secure all tools with nylon rope, before using on heights. Lift material and tools using

baskets and securing with rope.

C4

L4

Insignificant

HKSS

3. Slips, trips, & falls, Pinch point

,Possibilty of entaglement, Awkward

movement, cut injury,

C4

L3

Minor

1.

Maintain

good

housekeeping

all

the

time

and

watch

your

steps.

2.

Keep

your

hands

away

from

rotaing

parts.

3.

Do not wear loose clothings.

4.

Maintain

good

working

posture

to

avoid

ergonomic

hazards.

5.

Make

sure

all

the

power

tools

should

be

inspected

by

UNITED

and

inspection

sticker

C4

L4

Insignificant

HKSS

on it.

5. Use proper PPE.

6

6

7

7

1

/

7

100%