Photovoltaic Panel Emulator: Buck-Boost Converter & Microcontroller

Telechargé par

angibeau.ondoua

A photovoltaic panel emulator using a buck-boost DC/DC

converter and a low cost micro-controller

Dylan D.C. Lu

⇑

, Quang Ngoc Nguyen

School of Electrical and Information Engineering, The University of Sydney, NSW 2006, Australia

Available online 7 March 2012

Received 5 September 2011; received in revised form 8 February 2012; accepted 9 February 2012

Available online 7 March 2012

Communicated by: Associate Editor Nicola Romeo

Abstract

In order to facilitate the design and testing of photovoltaic (PV) power systems, a PV emulator which models the electrical charac-

teristic of a PV panel or array is needed. Among different approaches to modeling PV characteristic, namely the I–Vcurve, curve-fitting is

a popular approach. Even though a single high-order polynomial equation may accurately represent the I–Vcurve, the process of der-

ivation and implementation is rather complex. This paper hence proposes the use of piecewise linear approach which is easier to derive

and implement in a low-cost micro-controller. A two-switch buck-boost DC/DC converter is selected as the PV emulator and is analyzed.

Experimental results on a hardware prototype of the proposed PV emulator are reported to show the effectiveness of the approach.

Crown Copyright Ó2012 Published by Elsevier Ltd. All rights reserved.

Keywords: DC/DC converter; Photovoltaic; Micro-controller; Emulator

1. Introduction

The demand of photovoltaic (PV) power system installa-

tion has been increased over the past decade due to techno-

logical improvement, better environmental awareness,

lowered system costs, governmental initiatives, rising

electricity bills, etc. While these installed PV systems and

products are operating properly, there are still ongoing

issues to be investigated and solved. For example, reliability

of PV power systems (Petrone et al., 2008), PV power gener-

ation analysis (Ishaque et al., 2011; Paraskevadaki and

Papathanassiou, 2011) and electricity network performance

(van der Borg and Jansen, 2003) due to partial shading,

development of power electronics interfaces (Marsh, 2011,

2010), etc. All these research and development activities

require a stable, repeatable and variable PV source for

design and testing. Hence there is a need of a PV generator

emulator.

The main task for a PV generator emulator is to repro-

duce the I–Vcurve of a practical PV panel. There are differ-

ent approaches to performing this task. In Nagayoshi

(2004), a p–n photodiode is used and a DC power amplifier

increases the power level to match with that of a PV panel.

However, this approach requires a light source and associ-

ated circuit to reproduce the I–Vcurves of a PV panel. In

fact, a power electronics converter can mimic the I–Vcurve

accurately with only a DC input voltage source (Mukerjee

and Dasgupta, 2007). In Khouzam and Hoffman (1996),a

AC/DC buck converter is used as the PV emulator to emu-

late a PV cell circuit model. However this approach requires

the knowledge of the values of the parameters which are

usually difficult to obtain. In fact, to model a PV panel,

one may use the data available from the datasheet of the

PV panel manufacturer and derive an analytical model to

represent the I–Vcurves (Ortiz-Rivera and Peng, 2005).

0038-092X/$ - see front matter Crown Copyright Ó2012 Published by Elsevier Ltd. All rights reserved.

doi:10.1016/j.solener.2012.02.008

⇑

Corresponding author. Tel.: +61 2 9351 3496; fax: +61 2 9351 3847.

E-mail address: [email protected] (D.D.C. Lu).

www.elsevier.com/locate/solener

Available online at www.sciencedirect.com

Solar Energy 86 (2012) 1477–1484

Look-up table and curve fitting are two popular

approaches to implementing I–Vcurves of a PV panel by

the power electronics converters. Look-up table would

require a large memory storage of the micro-controller as

large amount of panel data is stored if many I–Vcurves

at different conditions and with high accuracy are imple-

mented. Hence to implement look-up table in a low cost

micro-controller which has limited memory space is usually

difficult. Curve-fitting approach in general uses one or

more polynomial equations to model an I–Vcurve and

needs a digital controller with fast computational speed

to find the solution. While this method requires less mem-

ory space, the non-linearity of the I–Vcurve requires the

equations to be of higher orders which may increase the

computational time substantially. A powerful DSP control-

ler is usually needed to produce very fast and accurate

results (Zhang and Zhao, 2010). Also the derivation pro-

cess of the polynomial equations for different conditions

such as insolation and temperature is rather troublesome.

In order to use curve-fitting efficiently on a low-cost

micro-controller, this paper introduces a PV emulator

using multiple simple linear equations to mimic an I–V

curve of the PV panel. This approach reduces computa-

tional time while maintaining sufficient accuracy and can

be implemented in a low-cost 8-bit micro-controller. The

paper is organized as follows: Section 2describes the circuit

and operation principle of the proposed PV emulator. Sec-

tion 3reports the experimental results of the emulator

which models a BP Solar SX-10 PV panel. Section 4dis-

cusses the limitations of the emulator and followed by

the conclusions in Section 5.

2. Description of the PV emulator

2.1. System overview

The PV emulator, as shown in Fig. 1, consists of a DC

input source, V

in

, a DC/DC converter for shaping the

output I–Vcurves of the PV panel, a micro-controller for

sensing the output voltage v

pv

and current i

pv

, calculation

and sending duty cycle command, and a gate driver for

amplifying the incoming duty cycle command suitable for

driving the power transistor (MOSFET in this case). The

output load R

L

is modeled as a variable resistor to repre-

sent an equivalent resistance of a maximum power point

tracker (MPPT).

2.2. Mathematical modeling of a PV panel

Apart from measuring an actual PV panel, one can also

use an analytical model to represent the data in the data-

sheet from the manufacturer to obtain the I–Vcurves of

a specific PV panel. In Ortiz-Rivera and Peng (2005), the

authors have generated an analytical model for a PV panel

which is adopted in this paper:

IðVÞ¼aImax si

1exp V

bðacþ1cÞðVmax þsVÞ1

b

ð1Þ

where ais the percentage of effective intensity of the light, b

is the characteristic I–Vcurve constant, cis the shading lin-

ear factor, s

i

is the rate of change with the temperature for

the current (A/°C), s

V

is the rate of change with the temper-

ature for the voltage (V/°C) and I

max

is the ideal maximum

current (when V=1 at STC).

For this paper, a PV panel from BP Solar (Model: SX-

10) is modeled. Assuming no shading and using a= 1 and

others values provided by the datasheet (BP Solar PC SX-

10 data sheet, 2003), a numerical expression of this PV

panel can be found:

IðVÞ¼ 0:65

1e1=b1V

b21 1

b

ð2Þ

Using the maximum power point condition at 16.8 V and

0.59 A, the value of bcan be calculated by (2) as

0.085. At 25 °C, (2) can be further simplified to:

IðVÞ¼0:65½1eðV=1:78511:7647Þð3Þ

Similarly at 75 °C one can get:

IðVÞ¼0:6711½1eðV=1:44511:7647Þð4Þ

Fig. 2 shows the MATLAB plot of the I–Vcharacteristic

curves of SX-10 PV panel Eqs. (3) and (4).

2.3. Two-line and multiple-line fitting approaches

To generate Nnumber of fitting lines, N+ 1 points from

the curve need to be selected. To begin with, a two-line

approach as shown in Fig. 3 is discussed. The two ends points

from the curve are the open-circuit voltage (21 V, 0 A) and

short-circuit current (0 V, 0.65 A). The third point is selected

(16.8 V, 0.62 A) as the maximum power point (MPP) of the

curve where the two lines converge. Therefore the two equa-

tions which represent the two lines are expressed as

IðVÞ¼0:65 0:004Vð5Þ

IðVÞ¼2:94 0:14Vð6Þ

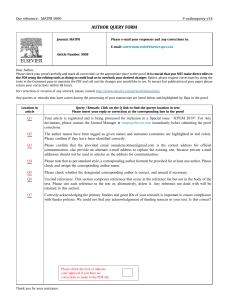

Fig. 1. Block diagram of the PV emulator.

1478 D.D.C. Lu, Q.N. Nguyen / Solar Energy 86 (2012) 1477–1484

To improve the accuracy of the curve-fitting method, five

lines as shown in Fig. 4 are used. Similarly, with six points

selected, the five equations which represent the five lines are

given by

IðVÞ¼2:94 9:2143e4V½for V¼0–14ð7Þ

IðVÞ¼0:8233 0:0133V½for V¼14–16ð8Þ

IðVÞ¼1:2633 0:0408V½for V¼16–18ð9Þ

IðVÞ¼2:1651 0:0909V½for V¼18–19ð10Þ

IðVÞ¼4:599 0:2190V½for V¼19–21ð11Þ

2.4. DC/DC converter

Among the basic converters, buck and buck-boost

converters are able to be implemented as the DC/DC

converter for the PV emulator. The design consideration

is that the converter is able to sweep through the entire

voltage range of the PV panel. For a buck converter, a

DC input voltage which is higher than the panel is required

as it is a step-down converter. The buck-boost converter is

more flexible as it can perform both step-up and step-down

functions. The boost converter which is a step-up con-

verter, however, can only operate when the input voltage

is lower than the output voltage hence it cannot reach

down to 0 V and cannot be used in this case.

3. Experimental setup and results

3.1. Design considerations and hardware description

To verify the proposed PV emulator for the BP SX-10

model, a hardware prototype is built and tested. The sche-

matic of the PV emulator circuit is shown in Fig. 5. The rea-

son to select a two-switch buck-boost converter for this

implementation is twofold. Firstly it can work with lower

input voltage (12–15 V) that reduces the power loss when

the input voltage is used to step down further for the

micro-controller circuit (5 V). If a buck converter is used,

the input voltage has to be higher than 21 V which is the

open-circuit voltage of the PV panel. Secondly, the output

voltage is non-inverting as compared to the single-switch

buck-boost converter with inverting output. The advantage

is that the output ground will be the same for the input

ground and ground of other equipment which is connected

to the output of the PV emulator, e.g. a MPPT switching

converter. Another advantage is that the use of either split-

ting power supply or opto-coupler and associated circuit for

negative voltage feedback sensing, which added complexity

and slowed down the response of the system, is eliminated.

The two-switch buck-boost converter consists of two

power MOSFETs (Q1 and Q2), two diodes (D1 and D2),

an inductor (L1) and an output capacitor (C1), as shown

Fig. 2. I–Vcharacteristics of SX-10 at 25 °C and 75 °C.

Fig. 3. Two-line curve fitting approach.

Fig. 4. Five-line curve fitting approach.

D.D.C. Lu, Q.N. Nguyen / Solar Energy 86 (2012) 1477–1484 1479

in Fig. 5. The two power transistors Q1 and Q2 share the

same driving pulses from the Gate Driver block. When

both transistors are closed, the inductor is charged by the

input voltage. When the transistors are turned off, the

inductor is discharged via two diodes (D1 and D2) to out-

put. By controlling the duty cycle of the transistors as a

result of the linear equations calculation as stated in Sec-

tion 2.2, the I–Vcurve of the PV panel is implemented.

For the micro-controller, a 8-bit PICAXE AXE-08M

chip is selected. It is a modified version of Microchip

PIC12F68 model. It has three ADC inputs and a PWM

output pin which is easily configured by a single-line com-

mand. The chip runs at 4 MHz and therefore it can operate

easily at 50 kHz switching frequency for the converter with

sufficient accuracy and speed.

The inductor (L1) is chosen to operate in continuous

conduction mode (CCM) as it produces less conduction

loss. A ±20% maximum current ripple in the inductor is

selected. At 50 kHz switching frequency, the minimum

inductance L

min

to meet such requirement is at 15 V input

and 21 V output (open-circuit voltage)

Lmin ¼Vin D

fsDi¼15 0:58

50000 0:4¼435 lHð12Þ

where V

in

is the input voltage, Dis the duty cycle of the

power switches, f

s

is the switching frequency, and Diis

the maximum current ripple.

In order to provide at least 12 V and floating gate drive

for the MOSFET, a high-side driver IR2117 is used. Since

the PICAXE chip operates at 5 V but the IR2117 driver

requires at least 9.6 V input, a simple transistor inverter

as a level lifting circuit is implemented. This small transis-

tor (2N7000) requires only 2.5 V to drive. When a high

pulse from PICAXE chip is generated, the transistor is

turned on and pulled the output to ground. When a low

pulse is generated, the transistor is turned off and output

is risen up to Vcc (12–15 V in this design).

The programming for PICAXE is done on a free pro-

gramming editor provided by PICAXE. Once the program

is written it can be downloaded to the PICAXE AXE-08M

micro-controller chip via a USB cable (AXE027) or RS-232

cable (AXE028) connecting the computer and the chip

(Download Socket in Fig. 5). This cable is not a normal

USB or RS-232 connector as it contains some electronic

parts and it is pre-programmed. The programming lan-

guage for PICAXE is similar to the BASIC language.

The program flow chart is shown in Fig. 6. The program

starts with defining the symbols for voltage and current

measurements and for counters. Then it outputs a small

duty cycle to start the buck-boost converter. Once the con-

verter operates, the program can take readings from the

voltage and current (V_sense and I_sense in Fig. 5)to

determine the operating point for the PV panel the con-

verter mimics. Note that we are using fractional open

voltage MPPT algorithm so only a voltage reading is

needed to operate the converter to the desired operating

point. The current measurement is only used for overload-

ing protection. The PICAXE-08M chip can contain maxi-

mum of 8 linear equations so we have used 5 linear

equations for 75 °C and 3 linear equations for 25 °C. The

Fig. 5. Schematic of the proposed PV emulator based on a buck-boost converter.

1480 D.D.C. Lu, Q.N. Nguyen / Solar Energy 86 (2012) 1477–1484

selection of what temperature to use is by providing a high

or low signal to available ADC input of the PICAXE (Pin

4). Here we selected signal high for 75 °C and low for

25 °C. After the temperature is selected, the program will

use the voltage reading to locate the nearest linear equation

to find out the operating point. A new duty cycle is then

determined and produced from the PWM pin of the PIC-

AXE and the converter duty cycle is updated. After that

the program goes back to the voltage and current checking

process and repeats the procedure. The full program code

for implementing the five-line approach is shown in Appen-

dix A.

3.2. Results

Fig. 7 shows the output voltage ripple of the PV emula-

tor is less than 450 mV at 50 kHz switching frequency. The

“On”and “Off”labels in the figure indicate the turn-on

instant and turn-off instant of the power transistors Q

1

and Q

2

for each switching period. The duration of “On”

period indicates the duty cycle of the transistors. And from

the waveform it can be observed that the converter is oper-

ating in continuous conduction mode (CCM) as the ripple

has only two stages, confirming our design in Section 3.1

and Eq. (12). Note that the voltage spikes during the

turn-on and turn-off instants and appeared beyond the hor-

izontal cursors are due to the pick-up of electromagnetic

noise from the voltage probe. Minimizing the ground loop

of the voltage probe will greatly reduce the pick-up. Fig. 8

shows the measured results on the prototype using the two-

line approach. The results are very close to the two operat-

ing lines. Fig. 9 shows further results on the five-line

approach at both 25 °C and 75 °C. Due to the memory

limitation of the micro-controller, only eight lines can be

implemented in a single program. Therefore Fig. 9 shows

5 lines for 25 °C and 3 lines 75 °C. Nevertheless, the mea-

sured results are closely matched with the theoretical

designed curves.

As shown in Fig. 10, the PV emulator reaches a maxi-

mum efficiency of around 80% near maximum power point

voltage for both temperature settings. The low efficiency

occurs at lower voltages because the output power of the

power converter is small and the switching losses of power

transistors and diodes are dominant. When PV emulator

Fig. 6. Program flow chart for implementation of 5-line for 75 °C and 3-

line for 25 °C of the BP SX-10 PV panel.

Fig. 7. Output voltage ripple of the PV emulator (Y-axis: 200 mV/div;

time scale: 10 ls/div).

Fig. 8. Comparison between experimental and theoretical results on two-

line approach.

D.D.C. Lu, Q.N. Nguyen / Solar Energy 86 (2012) 1477–1484 1481

6

6

7

7

8

8

1

/

8

100%