30/07/2018 How to Connect Motor Leads

https://www.ecmweb.com/motors/art-connecting-motor-leads 1/7

When it comes to terminating motor leads, there are many schools of thought —

each of which has a following that thinks its camp has the best method. This

article does not consider motor starting methods or internal connections.

Instead, it describes some procedures for connecting motor leads to incoming

power and a few advantages and disadvantages of each. It also explains how to

insulate joints and splices without using epoxy or tape kits.

Types of terminations. Acceptable methods of connection include both

mechanical and crimp compression lugs. Connections that use twist-on

connectors are only acceptable for wire sizes no larger than 10 AWG. [See the

National Electrical Code, 2017 (NFPA 70-2017), Sec.110.14A.]

Related: Practical Advice for Motor Protection

MAINTENANCE, REPAIR & OPERATIONS > MOTORS

The Art of Connecting Motor Leads

Practical tips and best practices for motor terminal box

connection methods and procedures

Jim Bryan | Jun 18, 2018

30/07/2018 How to Connect Motor Leads

https://www.ecmweb.com/motors/art-connecting-motor-leads 2/7

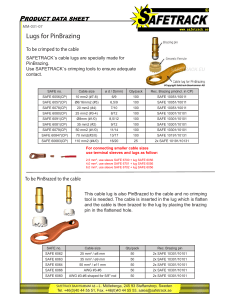

Mechanical compression lugs. These connectors secure the conductors with

set screws and are available in configurations having one to six or more barrels

(Photo 1). The lugs are installed on both the motor leads and the power supply

leads and then bolted together. Parallel motor leads and power supply

conductors should use lugs that have the same number of barrels as there are

leads.

Related: Is a Failing Bearing Causing the Vibration?

Tighten the set screws to secure the wire using the NEC recommended torque

values (Table 1). The bolt holding the lugs together should also be torqued to the

correct value (Tables 2, 3, and 4). If the lug and bolt are made of different

materials, they may expand and contract at different rates. In that case, use a

Belleville washer to maintain torque and help keep the bolt from stretching.

Photo 1. Mechanical compression lug.

Table 1. Recommended torque values for compression lug set screws.

30/07/2018 How to Connect Motor Leads

https://www.ecmweb.com/motors/art-connecting-motor-leads 3/7

Note: The torque values in Tables 2, 3, and 4 are approximate and should only be

used in the absence of manufacturer’s specific tightening values. Indeterminate

factors such as surface finish, plating and lubrication preclude the publication of

Table 2. Use these torque values when bolting together SAE Grade 5 metal-to-metal contact motor and power lead compression

lugs.

Table 3. Torque values to join North American Grade 5 or 8 coarse-thread, unlubricated compression lugs for motor and power

leads.

Table 4. These torque values apply when joining compression lugs for ISO Class 8.8 and 10.9 coarse-thread, unlubricated

materials.

30/07/2018 How to Connect Motor Leads

https://www.ecmweb.com/motors/art-connecting-motor-leads 4/7

factors such as surface finish, plating and lubrication preclude the publication of

accurate values for universal use.

Oxidation will increase the resistance and heating in the termination, so it’s a

good practice to coat the conductors and mating surfaces of lugs with an anti-

oxidant formulated for this purpose. The same applies to all other connections

discussed in this article.

Advantages and disadvantages. Mechanical compression lugs are easy to use

and require no special tools — typically, only a torque wrench with a hex head

(Allen) or slotted head socket are required. These connections also can be used

where the motor is terminated on a bus bar in the terminal box. One

disadvantage is that the secureness of the connection relies on the tightness of

the set screws and the bolts that hold the lugs together.

Crimp compression lugs. These lugs (Photo 2) attach to the conductors using

specially designed mechanical or hydraulic crimping tools. Since the lugs come in

various sizes and profiles (e.g., indented, hexagonal, or lobed), it’s critical to use

the right crimping tool to avoid loose connections, damaged conductor strands,

or misshapen crimps (Fig. 1).

Photo 2. Crimp compression lug.

30/07/2018 How to Connect Motor Leads

https://www.ecmweb.com/motors/art-connecting-motor-leads 5/7

Some crimp compression lugs are formed from a sheet of conductor material, so

the barrels have a seam. To prevent split seams and loose joints, position the

crimping tool so that it will indent the opposite side of the lug.

Crimped lugs bolt together in the same way as set screw lugs (which was

discussed earlier); but, for obvious reasons, they don’t have multiple barrels.

Therefore, each parallel conductor requires a lug, and a bolt holds all the lugs

together.

Advantages and disadvantages. The crimp connection will securely join the

conductor and lug if the proper tool is used. It also can be used where the motor

is terminated on a bus bar in the terminal box.

One disadvantage of crimped connections is that each different lug profile and

size requires a special tool. One way to minimize this problem is to standardize

on the products of one lug manufacturer. That way, only one set of crimping tools

may be needed. Smaller tools often accommodate three or more wire sizes.

Larger hydraulic tool sets can have multiple dies for different lugs.

Insulating joints. Motors with voltages up to 2kV. Splice insulation kits with

explicit instructions are readily available to make well protected joints for motors

operating at less than 2kV Some use epo resins others use arious tapes Both

Fig. 1. Improperly crimped lugs.

6

6

7

7

1

/

7

100%