Corona-Suppression Systems for HV Rotating Machines

Telechargé par

MOHAMED AMINE HEBRI

JEEE

Transactions

on

Dielectrics

and

Electrical Insulation

Vol.

9,

No.

4;

August

2002

569

Experience With Development and Evaluation

of

Corona-Suppression Systems for

HV

Rotating Machines

Hassan El-Kishky

Department

of

Electrical Engineering

The

University

of

Texas at Tyler

3900

University

Blvd.

Tyler,

TX

75799,

USA

Beant

S.

Nindra

National Electric Coil

800

King

Avenue (43212)

Columbus,

OH

43216, USA

Mazen Abdel-Salam

Department

of

Electrical Engineering

Assiut

University

Assiut, 71516, Egypt

and

Eugene Williams

California

Department of Water Resources

Divisron

of

Engineering

1416 9th St

Sacramento, CA 95814, USA

ABSTRACT

This paper presents the results of a project aimed at the development

of

reliable

corona-suppression systems for high voltage rotating machines. These systems

are

based

on

both conducting and semi-conducting dry and B-stage tapes as well as

paints of different resistivity. Three groups

of

anti-corona systems were developed;

namely, paint (on the slot portion)

-

paint

(on

the slot exit) system, paint

(on

the

slot portion)

-

tape (on the slot exit) system, and tape

(on

the slot portion)

-

tape

(on

the slot exit) system. Sample results of standard evaluation and acceptance tests

are presented. The accelerated life-aging test was run

on

test coil samples at the

National Electric Coil

HV

testing facility.

A

numerical 2-dimensional finite differ-

ence model for the electric potential and field analysis along the end-turn

zone

was

developed and the model results are used as guidelines through the design process

of the grading system. Laboratory test results

on

randomly selected sample coils

were confirmed by an independent testing facility. The proposed corona-suppres-

sion systems were applied

on

thousands

of

production coils.

1

INTRODUCTION

HE failure

of

a generator or a large motor can cause

tries due to non-planned outage costs in addition to the

cost

of

repairing and/or rewinding the machine. The reli-

ability

of

HV

machines depends mainly

on

the soundness

and integrity

of

the insulation system

[1-141.

Exposed to

complex electrical, mechanical and environmental stresses,

the stator winding’s main insulation is the most vulnerable

to deterioration and failure.

Long

exposure to internal and

surface discharges due to high localized concentration

of

electric stress can directly accelerates the deterioration

T

considerable financial losses to the utilities and indus-

and ultimately, complete failure of the ground-wall insula-

tion.

In

particular, intensified electric stress in the over-

hang portion

of

the high voltage stator winding of hydro-

electric machines is of special concern. Breakdown

of

the

gas adjacent to the insulation in the immediate vicinity

of

the slot exit leads to the development and propagation

of

discharges over the end-turns [1,5-7,13-201 which

in

tum

results in gradual degradation

of

the ground-wall insula-

tion. Therefore, the application of stress-grading systems

along the end-turn is considered essential for high voltage

machines.

It is a common practice that corona-suppression sys-

tems are designed such that a high voltage winding passes

a set of standard acceptance tests [1,13,14,21-241 as well

1070-9878/1/$17.00

0

2002 IEEE

570

El-Kishky

et

al.:

Experience With Development and Evaluation

of

Corona-Suppression Systems

as

meets customer’s special requirements. It is normally

required that a HV winding passes the

high

potential

blackout test

at

a level ranging from

100

to

150

percent of

the nominal line-to-ground voltage with

no

visual corona

discharges

[1,14,22-241.

Yet, it is not uncommon that spe-

cial requirements are set up, such as passing a voltage level

that exceeds 200%

of

the nominal line-to-ground in the

high voltage black-out test without detecting any visual

corona discharge on the stress-grading system. Moreover,

a randomly selected, sample of coils has to pass the stan-

dard voltage-endurance test with no repairs on the

corona-suppression system.

Proper design, analysis, and development of corona

suppression systems can significantly reduce the possibil-

ity of surface discharge inception and hence, extend the

life of the HV stator winding which

in

turn, significantly

enhances the reliability

of

HV machines.

This paper presents the results of a research project

carried out at National Electric Coil and University of

Texas at Tyler towards the development of reliable

corona-suppression systems for HV machines. The main

drive behind the project was the development of corona-

suppression systems, which can withstand elevated ther-

mal and electrical stresses. Moreover, the trend of thin-

ning ground-wall insulation for the purpose of machines

up-rating and subsequent stress intensification, i.e. use of

higher design electrical stress has become a major chal-

lenge to the research and development of insulation and

corona suppression systems in HV rotating machines. New

insulation and anti-corona systems that can withstand

higher electrical and

thermal

stresses

have

to

be

devel-

oped. Moreover, new test requirements and standards

have to be generated for the development, evaluation, and

acceptance of these systems. Within this work, several

anti-corona systems were developed, tested and applied to

thousands of production coils.

2

EXPERIMENTAL SET-UP AND

TESTING

Three groups of corona-suppression systems were de-

veloped and investigated; (a) cell (that portion of the sys-

tem within the

slot)

conducting paint and stress-grading

paint (paint-paint), (h) cell conducting paint and stress-

grading tape (paint-tape) and (c) cell conducting tape and

stress-grading tape (tape-tape). It is worth mentioning that

all tapes and paints used in this project are either silicon

carbide, graphite, or silicon carbide and graphite based.

In the mixing stages, necessaly amounts of graphite are

added to control the paint resistivity.

2.1

DEVELOPMENT TESTING

Mixing the ingredients to the required viscosity and low

voltage surface resistivity range is the primer of develop-

ing corona-suppression systems. Normally, those are pre-

pared into flat rectangular samples, which are usually left

to dry at the ambient temperature in case of paint or

oven-cured

in

case of tapes. After taking multiple resistiv-

ity measurements, a mean value is usually checked against

the required design range. The process may be repeated

with adjustments

if

deemed necessaly. It

is

quite normal

that measuring

on

flat samples may yield different results

from that along the corner of a finished coil. Perhaps this

may be attributed

in

part to the non-uniform application

of the material

in

addition to the difficulty of mounting

the measuring probe over the coil surface. Therefore, it is

important to take measurements

on

finished coils and es-

tablish a range of surface resistivity for the corona-sup-

pression system.

Nevertheless, visual inspection of the corona-suppres-

sion systems on the slot portion and the end-grading zone

is of considerable importance during the development

stage and before undergoing electrical testing. Surface

roughness, foreign material, and local damage of coatings

and tapes can lead to electric field intensification and

SUI-

face discharge. Based on the extent of the system irregu-

larities, a simple touch up repair or reapplication of the

system maybe performed before proceeding into further

testing.

Although, it is evident that the immediate part of the

stress-grading zone next to the overlap area plays the most

decisive part in the grading process, it is insightful to as-

sess the potential distribution along the whole grading

area. Figure

1

shows a schematic of the end-grading zone

of a HV coil. The potential distribution along a paint sys-

tem

is presented

in

Figure

2.

The

potential

distribution

along the stress-grading system was measured using a small

sphere contact probe tied

to

a standard

100

kV electro-

static voltmeter

[l].

The effect of stray capacitance was

significant on the measured potential distribution along

the stress-grading system. .~

2.2

EVALUATION AND ACCEPTANCE

TESTING

A set of sample coils of each system are prepared for

both evaluation and acceptance testing phase. Moreover,

each coil with stress-grading system applied

on

all corners

V

f

Ground

+tress-grading

systev

Copper

conductor

(HV

electrode)

Figure

1.

Schematic

of

the

end-turn

region

of

a

high

voltage

ma-

chine.

IEEE

Transactions

on

Dielectrics and Electrical Insulation

I

0

2

4

6

Msvurlng

pdrd

fmm

sk4

an

I

I

Figure

2.

Measured potential distribution

along

the stresr-grading

of

a

13.8

kV

coil

at room temperature

Ill.

can he treated

as

a

sample

of

four test specimens pro-

vided that consistency was maintained through the appli-

cation process and

a

minimum leads’ clearance does exist.

This phase

of

testing consists mainly of the high voltage

blackout test and the accelerated aging voltage endurance

test

[13,21-301.

All

tests are performed at room tempera-

ture. Systems with reproducible results

of

the high voltage

blackout test on

all

samples under similar conditions are

subjected to the accelerated aging voltage endurance test.

The integrity

of

the anti-corona systems under elevated

thermal and electric stresses can he assessed through the

study of several parameters and characteristics. This in-

cludes in particular, the recording of amount

of

discol-

oration and powder generation

as

well

as

any surface dis-

charge or arcing spotted on the corona suppression sys-

tem with reference to location and elapsed time under

test.

It

is

hoped that

a

following paper that will shed some

light on the interdependence

of

thermal and electric

stresses and the dynamic nature

of

degradation process in

the end-turn zone

of

HV

machines will he available to the

reader towards the conclusion

of

this project.

3

MODELING AND ANALYSIS

The model is based on numerical solution of the hound-

aly

value problem governing the electric.field distribution

along the end-turn region using the finite difference

method (FDM)

[31-331.

It

is

worth mentioning that

al-

though the model

is

not meant to provide extensive analy-

sis

of the corona-suppression system,

it

provides some

necessary guidelines throughout the design process. Re-

ferring to Figure

1,

x-, y-. and z-coordinates extend along

the axial coil length outside the slot, the coil height, and

the coil width, respectively.

To

simplify the modeling pro-

cess, the following assumptions are made:

(1)

Electric field

is

not z-dependent which reduces the model

to

a

2-dimen-

Vol.

9,

No.

4;

August

2002

571

sional problem.

(2)

The stress-grading system is approxi-

mated by a linear resistive layer

of

finite thickness.

(3)

No

free charge exists at the interface between the gradient

system and the adjacent media.

The electrostatic field distribution

is

obtained by solv-

ing the boundary-value problem formulated in the region

under consideration

V.(

a*)

=

0

(1)

.I=

iE

(2)

where,

6

is the electric potential and

2

is

the complex

permitivity

of

the medium, which is given by

where

p

is the volume resistivity

of

the medium.

The potential solution is unique when

Jr

satisfies a set

of

specified boundary conditions. Referring to Figure

1,

Dirichlet boundary condition must be imposed on the

copper conductor where the voltage

is

given by the nomi-

nal line to ground value,

V

*=V

(4)

Similarly, on the grounded screen, Figure

1,

the potential

boundary condition is given by

*=0

(5)

In the absence

of

a

perfect conductor, no surface cur-

rent exists at the insulation-stress grading, insulation-air,

or the stress grading-air interface. Using the complex

perimitivity notation given by equation

(3),

the Neumann

boundary condition applies at

all

interfacial boundaries.

At the interface between the

ith

and

kth

medium

Extending the modeled region between

(x

=

0)

which is

located at nearly

4“

deep inside the slot, Figure

1,

to

the

end

of

the corona-suppression system

(x

=

L), the hori-

zontal component

of

the electric field across both ends

(x

=

0,

x

=

L)

can be ignored and the boundary condi-

tions

on

both sides

of

the insulation may be approximated

by

-=

0

dX

(7)

Considering the geometrical complexity

of

the domain

and the type

of

boundary Conditions, the solution

of

this

boundary-value problem can only he obtained numeri-

cally. In this study FDM with non-uniform grid

is

used to

calculate the electric potential and field distribution along

the modeled end-turn portion

of

a

high voltage coil, Fig-

572

El-Kishky

et

al.:

Experience With Development and Evaluation

of

Corona-Suppression Systems

ure

1,

A

versatile

FORTRAN.90

program was built

for

analysis of the problem under consideration. The program

is capable of simulating both linear and non-linear resis-

Surface

resistance

of

end-grading system

tive stress-grading systems, however, only the results of a

simple resistive grading system are presented here. In a

system coating

0.5kV

1.0kV

250Gn

SOGR

20.0 to

3.5

to

k

Qsq

300Gn.

80GR

Table

1.

Low

voltage resistivity measurement

of

corona-suppression

coatings at

room

temperature.

Resistancc

of

cell

conducting

..

s,,$~~s~~n

nonlinear resistive grading system, the resistivity can he

Paint-paint

1-5.0

15.0 to 2.0 t"

expressed empirically

as

a

function of both the electric

dated each iteration using the most recent value of the

Taoe-taoe

1-40

20

to

3.5

to

kW2/sq

Paint-tape

1-5.0

field and temperature,

p

=

f(E,T).

The resistivity is up-

L1

electric field and temperature. If

$PI,

Ef",

ppl,

TP'

and

k

n/sq

300Gn

80GR

*:+I,

El""',

pl"+'),

Tpt"

are

the

corresponding values

.

..

.

..

.

of the electric potential, field, and temperature at node

k

after iterations

n

and

n

+

1,

respectively, this iterative

process can he given by

Table

2.

Experimental test resuits

of

corona-suppression systems

on

13.8

kV Epoxy coils. Voltaee

Both electric field and thermal analysis of nonlinear re-

sistive grading systems are yet to he presented in a

manuscript under preparation.

4

RESULTS

AND DISCUSSION

C0rO"a.

suppression

ac

high voltage

system black out test

Paint-oaint

no

visual

systcm-11 corona spotted

3

four-coils

at 16kV

samples

Paint-paint

no

visual

system-l

corona

spotted

3

four-coils

at 16kV

I

endurance test at

30kY

and

100°C

dctcrioratian

spotted

in

a

2" wide

zone

next to the

overlap

area

after

130

Hrs

no

deterioration

spotted after

400Hrs

I

samples

Paint-tane

no

visual

no

deterioration

r~

~ ~~~~~~ ~~~

The project

was

focused on developing corona suppres-

6

four-coils

corona spotted spatted

after

sion systems for both Epoxy and Polyester vacuum pres-

samples at 22kV

470

Hrs

sure impregnated (VPI) coils taking into consideration the

Tape-tape

no visual

not applied

variation in the design and manufacturing process

of

both

systems such as the average electric stress in the insula-

tion

or

volts-per-mil (VPM) and the curing cycle require-

ments.

Figure

2

shows the measured potential distribution

along the stress grading system of a

13.8

kV, Epoxy Coil at

room temperature. The salient non-hearity may be at-

2 four-coils

corona

spotted

samplcs at 12kV and

(12kV and 16kV

level

I6 kV level)

for

the accepted anti-corona systems according to the cri-

terion mentioned above.

tributed to the electric field intensification in the region

adjacent to the slot exit.

Both conducting and stress grading paints and tapes are

classified according to the supplier and the initial resistiv-

ity level. Several samples of each group were manufac-

tured and the low voltage surface resistivity at

500

V and

1000

V

(0.5

and

1.0

kV/cm) levels was measured at differ-

ent locations along the stress-grading zone as well

as

on

the cell portion. The average low and average high values

are used to determine the range of variation of surface

resistivity. Samples with anti-corona systems' surface resis-

tivity values drastically different from the established range

are corrected or reworked.

All

samples are subjected to ac

high voltage blackout test, then only passing systems in

which no sign of visual corona during black-out of repeti-

tive samples are subjected to accelerated aging through

voltage endurance test.

Table

1

shows the average measured surface resistance

along the cell portion and along the stress-grading zone

The results of the ac HV blackout and voltage en-

durance testing on Epoxy coils with different corona sup-

pression systems are displayed in Table

2.

Although some

of the systems showed better performance than others,

generally, all the anti-corona systems were able to meet

the basic requirements of application on high voltage ro-

tating machines rated

6.6

kV and above. Despite the fact

that it is economic and easier to apply and repair, the

paint-paint system suffers from application inconsistency

which may he attributed to low-skilled workmanship in

addition to its vulnerability to different levels of visual

damage and its volatility during installation. On the other

hand, anti-corona systems based on B-stage tapes showed

better consistency, durability and discharge resistance.

Yet, the lack of bonding of anti-corona tapes to the

ground-wall insulation could he

a

major problem, which

may he attributed to the lack of resin contents in the B-

stage tape

in

addition to other factors such

as

pressure

and other curing cycle parameters. Repair of such systems

IEEE Transactions

on

Dielectrics and Electrical lnsulotion

Vol.

9,

No.

4;

August

2002

573

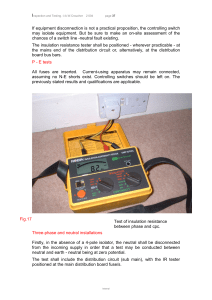

Figure

3.

Stress-grading paint deterioration under elevated electri-

cal and thermal strcsses.

is difficult and may become even impossible without dam-

aging the upper most layers of the ground insulation.

Figure

3

shows one of the coil samples that passed a

16

kV ac HV blackout test undergoing the voltage endurance

test

[21].

There

is

an obvious discoloration across a

5

cm

wide area of the stress-grading system past the overlap

zone. The discoloration may be attributed to relatively high

discharge activity developed

in

the region after about

130

h

in

voltage endurance, which demanded intenention to

repair the paint.

Systems based on cell conducting paint along with

B-

stage stress-grading tapes have shown the best perfor-

mance through the ac HV blackout test on Epoxy coils,

Table

2.

Test voltages exceeding

22

kV line to ground were

applied with no trace of visual corona along the anti-

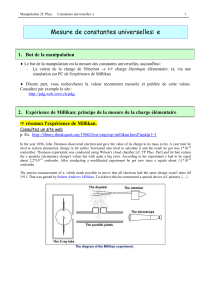

corona system. Figures 4a and 4b show the B-stage

stress-grading system applied on a

13.8

kV Epoxy coil be-

fore and after the voltage endurance test. No visual corona

or

damage of the stress-grading system was detected within

or after the voltage endurance test, Figures 4a and 4b.

Moreover, the surface resistivity of the stress grading

structure remained within the established design range,

Table

1,

after exposure

to

elevated thermal and electrical

stresses for more than 400 hours. Nonetheless, no deterio-

ration was noticed on the end-grading portion of the

anti-corona system after taking the coils out of the voltage

endurance test, Figures 4a and 4b. This may be attributed

in

part to the inherent capability of the resin in the B-stage

tape to withstand elevated thermal stresses. Therefore, we

recommend the paint-tape system for application on ma-

chines with up rated windings or running under non-

favorable environmental conditions.

According

to

a contract between National Electric Coil

and one of its customers, the paint-tape system applied on

the customer's 13.8 kV coils has to be tested by an inde-

pendent laboratoty selected by the customer in addition

to all contract testing performed at National Electric

Coil's

(b)

Figure

4.

(a)

Paint-tape

corona

suppression system before voltage

endurance testing;

(b)

Paint-tape

corona

suppression system after the

voltage

endurance

testing.

HV testing facility. The system has to pass a voltage level

of

16

kV in the high potential blackout test with no visual

corona and also pass the voltage endurance test with no

repairs on the system. Two 10-coils samples of the paint-

tape anti-corona system were sent

to

a Canadian indepen-

dent testing laboratoty for evaluation of the new system

along with the assessment

of

the integrity

of

the ground-

wall insulation. Sensitive night vision cameras were used

throughout the high potential blackout test where no vi-

sual corona was spotted at a level of 16 kV. The labora-

tory reported

no

repairs done on the system through the

voltage endurance test.

The tape-tape corona suppression system applied on

Epoxy coils showed good performance under ac HV

blackout test where

two

stress-grading system designs were

made to meet a minimum of blackout test requirements of

12

kV and

16

kV, respectively. The main experience was

the difficulty of controlling the surface resistance of the

cell tape as well as adherence of the tape to the ground-

wall insulation. The latter may depend to some extent

on

the porosity of the tape as well as on the

VF'I

cycle pa-

rameters.

Table

3

shows the results of testing Polyester coils with

tape-tape corona suppression systems. Cell conducting

tapes as well as stress grading tapes from different suppli-

6

6

7

7

8

8

1

/

8

100%