PWM Voltage Effects on Induction Motor Stator Windings

Telechargé par

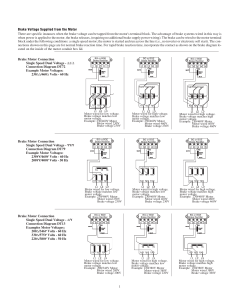

MOHAMED AMINE HEBRI

IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 14, NO. 1, JANUARY 1999 23

Predicting the Transient Effects of PWM Voltage

Waveform on the Stator Windings of

Random Wound Induction Motors

G. Suresh, Student Member, IEEE, Hamid A. Toliyat, Senior Member, IEEE,

Dudi A. Rendusara, Student Member, IEEE, and Prasad N. Enjeti, Senior Member, IEEE

Abstract—In this paper, the effect of pulsewidth modulation

(PWM) voltage waveform on the voltage distribution among

the stator windings of random wound cage induction motors

is studied. First, a method of estimating the high-frequency

distributed-circuit parameters of the motor using finite-element

analysis is described. From these parameters, an equivalent

circuit is formed with the windings represented by partially dis-

tributed and partially lumped parameters. Using this equivalent

circuit, the voltage distribution among the turns and coils of

the motor are simulated using the SABER simulation package.

Through simulation, the effect of rise time of the PWM wavefront

on the voltage distribution is studied, and it is shown that the

rise time of the wavefront has influence on the additional voltage

stress on the line-end coil. In order to validate the simulation

procedure adapted, the simulation results are compared with

experimental results.

Index Terms— , induction motor, PWM drives, transient

effects, voltage stress.

I. INTRODUCTION

WHEN INDUCTION motors are fed from pulsewidth

modulation (PWM) inverter power supplies, the stator

winding is subjected to high-voltage stresses caused by the

train of wavefronts in the PWM voltage waveform. The volt-

age distribution among the turns and coils is highly nonlinear

because of the high of the wavefront, and this often

results in higher voltage stresses in the first few turns of the

line-end coil. These voltage stresses are several times higher

compared to stresses caused by sinusoidal waveforms. The

voltage withstanding capability of the commonly used magnet

wire is worsened when waveforms with high ’s and

fast switchings are imposed on the windings. This causes

premature failure of insulation and, hence, results in forced

outage of the drive system.

Most of the low- and medium-size induction motors are

fed from PWM voltage source inverters employing insulated

gate bipolar transistor (IGBT) switches because of several

advantages. With the advancement in power semiconductor

technology, it has been possible to keep the switching times

as low as 0.1 s. Although the inverter switching losses are

Manuscript received March 18, 1997; revised May 14, 1998. Recommended

by Associate Editor, A. Goodarzi.

The authors are with the Department of Electrical Engineering, Texas A&M

University, College Station, TX 77843-3128 USA.

Publisher Item Identifier S 0885-8993(99)00284-7.

reduced by keeping the switching time low, the insulation

integrity is affected because of the detrimental effects of the

sharp wavefronts on the motor windings. This problem is

worsened when the motor is connected to the inverter through

feeder cables. Depending on the surge impedances of the cable

and motor, the motor terminal voltage can be much higher than

the dc bus value and sometimes can even double because of

voltage reflections.

Many papers discuss the impact of PWM waveforms on

the motor windings [1]–[8]. In [1] and [2], the impact of

PWM waveforms on the random wound induction motors is

analyzed. References [3] and [4] give methods of simulating

the voltage distribution among the turns of random wound

machines using equivalent circuits. The parameters used in

the equivalent circuits are based on terminal measurements.

Reference [6] considers the effect of feeder cable and presents

a simulation procedure to compute machine terminal voltage

transients. References [3]–[5] and [7]–[12] explain the voltage

reflections caused at the motor terminals due to long feeder

cables and a few practical ways of suppressing the terminal

voltage transients. However, the distributed-circuit parameters

of the individual turns would be needed if the voltage dis-

tribution among the turns and coils needs to be estimated.

In the past, field analysis results have been reported for

studying high-frequency field effects in form wound induction

motor parameters for surge studies [13]–[16]. In this paper,

a method of deriving these parameters for a random wound

induction motor using finite-element analysis is presented.

Random wound motors differ significantly from form wound

motors because of their constructional differences. In form

wound motors, each turn in a coil occupies the same relative

position within the slot unlike random wound motors. Using

the method described, it is possible to compute the parameters

corresponding to different rise times of the PWM wavefront.

With the partially distributed surge equivalent circuit, SABER

[23] simulation is performed in order to estimate the voltage

distribution among the turns and coils of the motor. In order

to validate the method proposed, the simulation results are

compared with experimental results.

The organization of the paper is as follows. Section II

describes the problem under consideration in detail. Section III

details the method of estimating the high-frequency param-

eters of the motor winding. In Section IV, the details of

the partially distributed equivalent circuit model used for

0885–8993/99$10.00 1999 IEEE

24 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 14, NO. 1, JANUARY 1999

simulation are presented. Simulation and experimental results

are presented and discussed in Section V. A brief review

of recently published literature on the practical remedies is

given in Section VI. Section VII presents the summary and

conclusions.

II. DESCRIPTION OF THE PROBLEM

In order to estimate the voltage distribution among the coils

of the stator during a typical PWM wavefront, it is necessary

to use a high-frequency distributed-circuit model for the stator

winding [15]. This is mainly because of the high-frequency

content of the wavefront with sharp rise time. The machine

behavior at such high frequencies (which are in the order of

megahertz) corresponding to fast switching transients is totally

different than at power frequency, and, hence, calculating

the distributed parameters is very difficult. For example, at

megahertz-range frequencies corresponding to switching times

in the order of fractions of microseconds, the steel laminations

act like flux barriers, and, hence, most of the flux produced

by the windings will be leakage fluxes. The high-frequency

eddy currents induced in the rotor confine the flux to the

air gap itself, and, hence, there will be no flux penetration

across the air gap. Since the magnetic steel laminations act

as flux barriers, the flux lines are confined to the stator slot

portion itself, as will be shown later. It is also essential to

represent the winding by its distributed equivalent circuit since

the wavelength of the high-frequency traveling wave is very

small compared to that of the power frequency.

The distributed-circuit parameters to be calculated for the

individual turns are the self-inductance and resistance of each

turn, mutual inductances between turns within the same slot,

turn-to-ground capacitances, and turn-to-turn capacitances [3],

[4], [7], [8], [15], [16]. The distributed parameters of the

individual turns depend on the slot geometry and also on

their relative position within the slot. For example, a turn

located near the slot wall will have a higher turn-to-ground

capacitance compared to a turn located in the middle of

the slot. A turn which is located in the middle of the slot

will have a lesser turn-to-ground capacitance because of the

larger separation between the turn conductor and ground.

Furthermore, the conductors around the turn located in the

middle of the slot act as a shield between the turn and ground.

These factors complicate the computation of the parameters.

Another difficulty with random wound machines is that the

relative positioning of the individual turns in different slots

may not be the same.

In order to overcome these difficulties, finite-element anal-

ysis techniques are used to compute the circuit parameters of

the coils even at high frequencies. A single-slot model of the

machine will be enough to calculate all the parameters required

for simulation if it is assumed that the relative positioning of

the individual turns within the slots remains the same in a

given phase which is a reasonably good assumption.

The following are the advantages of using finite-element

analysis.

• Actual material properties can be defined for computing

the parameters.

• High-frequency field effects on the parameters can be

considered.

• The exact geometry of the slot can be modeled for

computing the parameters.

The details of the finite-element model along with the

procedure of computing the various parameters are presented

in the following section.

III. FINITE-ELEMENT ANALYSIS OF THE SINGLE-SLOT MODEL

For computing the equivalent circuit parameters of the coils,

a single-slot model of the cage induction motor was used. The

motor used for analysis in the present work has the following

specifications: 3 HP, 3 phase, 4 pole, 60 Hz, and 230/460 V.

The stator has 36 slots and has a single-layer random winding

with 6 coils per phase, each coil having 54 turns.

The Ansoft [24] package is used for performing finite-

element analysis of the single-slot model which basically

consists of one stator slot pitch with all the turns placed

randomly to simulate random winding. The slot wall insulation

and individual turn insulation are also modeled in order to

compute the capacitance values accurately. Although the flux

lines do not penetrate the air gap, the rotor slot portion is also

modeled. The package computes the field quantities per unit

length of the single-slot model assuming symmetry in the axial

direction. There are different solvers available in the package

for performing electric and magnetic field analysis. From the

finite-element analysis results, the impedance and capacitance

matrices are obtained which are then used for forming the

equivalent circuit. The details of the finite-element analysis

are explained in the following sections.

A. Computation of the Inductance and Resistance Matrices

For computing the inductance and resistance matrices, an

eddy-current analysis option available in the Ansoft package

is used. Once the geometry of the single-slot model is created,

an eddy-current analysis solver is used. The setting up of

the eddy-current analysis includes setting up the excitation,

defining boundary conditions, etc. When eddy-current analysis

is used, the package automatically defines each conductor as

a current source. The only boundary condition used is balloon

boundary condition in which a surface far away from the slot

model is set to zero magnetic vector potential. The frequency

for which the eddy-current analysis has to be computed is

also defined in the analysis.

The main advantage of using an eddy-current solver is

that the effects of time-varying currents in parallel conductors

are considered in the analysis. Furthermore, the eddy-current

effects caused in the conductors at high frequencies are taken

care of. Time-varying currents flowing in a conductor produce

a time-varying magnetic field in planes perpendicular to the

conductor. In turn, this magnetic field induces eddy currents

in the source conductor and in any other conductor parallel to

it. The eddy-current field solver calculates the eddy currents

by solving for and in the field equation

(1)

SURESH et al.: PREDICTING THE TRANSIENT EFFECTS OF PWM VOLTAGE WAVEFORM 25

where is the magnetic vector potential Wb/m, is the elec-

tric scalar potential, is the relative magnetic permeability,

is the angular velocity at which all quantities are oscillating,

is the conductivity, and is the relative permittivity.

The simulator computes the impedance matrix in two steps.

First, it solves for the inductance matrix associated with the

model. Then it solves for the resistance matrix and then

computes them to form the impedance matrix using the

relationship

(2)

The individual elements in the impedance matrix are com-

puted as follows. The simulator generates an eddy-current field

solution for each conductor in the model. The first turn is set

to 1-A current in the first solution with all the other turns set

to zero current. In the second solution, only the second turn is

set to 1-A current with all the other turns set to zero current.

After each field solution, the inductance and resistance are

computed using the following relations:

(3)

(4)

where is the energy stored in the magnetic field (J), is

the ohmic loss (W), and is the peak value of the current

(amp) (in this case, the peak value of the current is 1 A).

After each field solution, the solver calculates the self-

inductance of the conductor which was assigned 1-A current

during the analysis. Also, the mutual inductances of the

conductor with all the other conductors are computed. Sim-

ilarly, the resistance terms are also computed after each field

solution. The final output of the eddy-current analysis is a

54 54 impedance matrix. Thus, the complete impedance

matrix required for the circuit simulation is obtained in one

eddy-current analysis.

The flux plot obtained from the eddy-current analysis shows

some interesting results of the high-frequency behavior of the

machine. The flux plot obtained from the eddy-current analysis

is shown in Fig. 1. The flux plot shows that the flux lines

are confined to the slot portion itself, and the flux lines do

not penetrate the steel laminations because of high-frequency

effects. Also, there is no flux passing through the air gap to

the rotor. The impedance matrix also shows that the different

turns have different impedances depending on their relative

positioning within the slot.

B. Computation of the Capacitance Matrix

The capacitance matrix is also computed in a similar way.

For computing the capacitance matrix, the Ansoft electrostatic

analysis package is used. During the electrostatic analysis,

each conductor is defined as a voltage source and assigned

1 V with all the other conductors set to 0 V. A boundary

value condition is used for electrostatic analysis in which the

stator laminations are defined to be at zero electric potential.

The electrostatic field simulator computes the static electric

fields arising from potential differences and charge distri-

Fig. 1. Flux distribution in the slot during eddy-current analysis.

butions. The field simulator solves for the electric potential

in the field equation derived from Gauss’ law and is

given by

(5)

where is the charge density.

After each field simulation, the capacitance values as-

sociated with the conductor which was assigned 1 V are

computed, which includes the turn-to-ground and turn-to-turn

capacitances between the turn being excited and all the other

turns. Thus, 54 different solutions are required to obtain

the capacitance matrix. However, one electrostatic analysis

performs all the simulations required automatically. After the

electrostatic analysis is complete, a capacitance matrix of order

54 54 is obtained. The capacitance between conductors “ ”

and “ ” is calculated as follows:

(6)

where is the energy in the electric field associated with

flux lines that connect charges on conductor “ ” to those on

conductor “ ” From the analysis results, it was found that the

turn-to-ground capacitance values in the capacitance matrix

are all not equal because of their relative positioning.

For computing the capacitance matrix, electrostatic analysis

is performed because of the fact that the variation of the

capacitance terms with frequency is negligible unlike the

inductance and resistance values [4], [15].

This completes the computation of the equivalent circuit

parameters of the stator winding which are used for simulating

the voltage distribution. In the present work, it is aimed at ex-

plaining a method of using finite-element analysis techniques

to estimate the high-frequency circuit parameters of the turns

in the stator winding. Using this method, the circuit parameters

are computed at two different frequencies and later used

26 IEEE TRANSACTIONS ON POWER ELECTRONICS, VOL. 14, NO. 1, JANUARY 1999

Fig. 2. Partially distributed equivalent circuit of the line-end coil.

for circuit simulation. The parameters of the winding which

correspond to the rise time of the wavefront for which analysis

has to be done were used for simulating the circuit. For

example, when it is desired to simulate the voltage distribution

with a 0.2- s wavefront, the surge equivalent circuit is formed

with parameters corresponding to 5-MHz frequency and so on.

The details of circuit simulation performed to determine the

nonlinear voltage distribution are explained in the next section.

IV. SIMULATION OF SURGE EQUIVALENT CIRCUIT

In the previous section, the methods of estimating the high-

frequency parameters of the turns and coils were explained.

The procedure adopted to form a partially distributed equiv-

alent circuit from these parameters in order to estimate the

voltage distribution among the turns and coils is presented in

this section.

The motor used for analysis has 36 stator slots with 6 coils

per phase, each coil having 54 turns, two groups of 3 coils each

connected in parallel. Although it is desired to represent all the

turns in the stator phases with distributed parameters, it is not

practical to implement it, and, hence, a simplified equivalent

circuit as suggested in [4] is used for simulation. It is well

known that during the PWM wavefront, the first few turns

in the line-end coil will have higher voltage stress compared

to the other turns. Hence, for circuit simulation, the first five

turns of the line-end coil are modeled with their distributed

parameters. The other turns in the first coil as well as the other

coils in the phase are represented by their lumped parameters.

For obtaining the lumped parameters, the diagonal terms in

the impedance matrix and capacitance matrix are considered,

and the nondiagonal terms are ignored.

Fig. 2 shows the distributed-circuit model of the line-end

coil. The other coils in the phase are modeled with their

lumped parameters. The parameters used in the circuit are

turn resistances, turn self-inductances (mainly leakage), turn-

to-turn mutual inductances, turn-to-ground capacitances, and

turn-to-turn capacitances. In order to simulate a typical PWM

wavefront, a step voltage source is used as input to the

equivalent circuit, and the circuit is simulated using SABER

package on a SUN platform. The rise time of the step voltage

source can be changed to any desired value depending on the

rise time of the actual wavefront in the inverter output.

A. Voltage Distribution Among the Machine

Winding with 0.2- s Rise Time

For simulating the voltage distribution among the turns of

the winding corresponding to 0.2- s rise time, the circuit

described earlier was used. A rise time of 0.2 s is chosen

since the switches in the inverter used to perform experiments

have a turn-on time of 0.2 s. The first few turns of the phase

A windings are represented by their distributed parameters

with the remaining turns in phase A modeled by lumped

parameters. The phase B winding is modeled wholly by its

lumped parameters. It is assumed that only phases A and

B are conducting, and, hence, phase C is not modeled. All

the parameters are obtained from the finite-element analysis

results which were performed at 5-MHz frequency. In SABER,

the rise time of the step voltage source is set at 0.2 s and

its amplitude at 295 V which is the dc bus voltage, and

the transient analysis option is used to obtain the voltage

distribution. The transient analysis results include the voltage

distribution among all the turns and coils modeled.

B. Voltage Distribution Among the Machine

Winding with 0.1- and 1- s Rise Time

Simulations of the transient voltage distribution which cor-

respond to a rise time of 0.1 and 1 s were also carried

SURESH et al.: PREDICTING THE TRANSIENT EFFECTS OF PWM VOLTAGE WAVEFORM 27

Fig. 3. PWM wavefront model used for simulation (rise time of the wave-

front s).

out in the same way as that of the previous case mainly to

study the effect of rise time of the wavefront on the voltage

distribution. The same equivalent circuit is used for this

case also. The parameters used in the simulation are derived

from the finite-element analysis results performed at 1-MHz

frequency corresponding to 1- s rise time. While performing

analysis for 0.1 s, the parameters obtained at 5 MHz are

used assuming these parameters to be almost equal to 10

MHz. Detailed discussion on the simulation results and the

comparison with the experimental results are presented in the

next section.

V. DISCUSSION AND COMPARISON OF

SIMULATION AND EXPERIMENTAL RESULTS

In this section, the results obtained through simulation are

discussed and compared with the experimental results. The

details of the induction motor used to obtain the experimental

results are given in the Appendix. The IGBT switches used in

the inverter have a typical rise time of 0.2 s. As described in

the previous section, the first set of simulations is carried out

with rise time equal to 0.2 s in order to make comparison

with experimental results.

A. Comparison of Simulation and Experimental

Results with 0.2- s Rise Time

Fig. 3 shows the PWM wavefront used for simulation. The

dc bus voltage for this operating condition is 295 V. Fig. 4

shows the simulated voltage drop across the line-end coil. It

should be noted that the voltage reaches a peak value of 105

V and oscillates before settling down at around 50 V. Fig. 5

shows the corresponding experimental results. The upper trace

in Fig. 5 shows the inverter output voltage which is applied

to the motor through a short cable. Trace 2 shows the motor

terminal voltage, and trace 3 shows the line-end coil voltage

which corresponds to the result shown in Fig. 4. Comparing

these two results, it should be noted that the oscillations seen

in the simulation results are not so much pronounced in the

experimental results. A close agreement between simulation

Fig. 4. Simulated voltage drop across the line-end coil (rise time of the

wavefront s).

Fig. 5. Experimental results of a PWM induction motor drive with a short

cable between the inverter and motor. Trace 1: inverter output voltage. Trace

2: motor terminal voltage. Trace 3: line-end coil voltage. Trace 4: Turn 1

voltage in the line-end coil.

and experimental results cannot be expected anyway because

of the complex nature of the problem and also the assumptions

made in simulation and in the formation of the equivalent

circuit. Interestingly, the peak values of the two voltages,

viz., simulated and experimental line-end coil voltages, match

reasonably well which is important from the motor design

point of view. Also, the two waveforms take around the same

time to settle down to the final steady-state value.

Fig. 6 shows the simulated voltage wave form across Turn

1 of the line-end coil with 0.2- s rise time. In Fig. 5, Trace 4

shows experimentally recorded voltage drop across Turn 1 of

the line-end coil which corresponds to Fig. 6.

B. Simulation Results with 0.1- and 1.0- s Rise Time

As described in the previous section, the circuit simulations

were carried out with 0.1- and 1- s rise time for the step

6

6

7

7

8

8

1

/

8

100%