See discussions, stats, and author profiles for this publication at: https://www.researchgate.net/publication/233656616

Electrolytic Sodium Hypochlorite System for Treatment of Ballast Water

ArticleinJournal of Ship Production · August 2006

DOI: 10.5957/jsp.2006.22.3.160

CITATIONS

32

READS

6,869

8 authors, including:

Some of the authors of this publication are also working on these related projects:

Seattle Seawall Project View project

Onsite sodium hypochlorite generaton for treatment of ballast water View project

Jeffery Cordell

University of Washington Seattle

139 PUBLICATIONS3,014 CITATIONS

SEE PROFILE

Bryan Nielsen

WaterTectonics

4 PUBLICATIONS36 CITATIONS

SEE PROFILE

Nissa C Ferm

National Oceanic and Atmospheric Administration

5 PUBLICATIONS202 CITATIONS

SEE PROFILE

David J. Lawrence

National Park Service

33 PUBLICATIONS1,248 CITATIONS

SEE PROFILE

All content following this page was uploaded by Jeffery Cordell on 01 October 2015.

The user has requested enhancement of the downloaded file.

Electrolytic Sodium Hypochlorite System for Treatment of

Ballast Water

Rudolf C. Matousek,*David W. Hill,* Russell P. Herwig,

†

Jeffery R. Cordell,

†

Bryan C. Nielsen,

†

Nissa C. Ferm,

†

David J. Lawrence,

†

and Jake C. Perrins

†

*Severn Trent DeNora, Sugar Land, Texas, USA

†

University of Washington, Seattle, Washington, USA

The potential problems of organisms introduced by ballast water are well docu-

mented. In other settings, electrolytic generation of sodium hypochlorite from sea-

water has proven to be a simple and safe method of handling and injecting a biocide

into water. After the hypochlorite oxidizes organisms, it reverts back to the chloride

ion. Mesocosm-scale testing of this technology combined with filtration, using organ-

isms from Puget Sound, Washington, demonstrated that hypochlorite generation and

use may be a viable method to eliminate aquatic nuisance species from ballast water

while minimizing disinfection byproducts and residual toxicity. These experiments

were conducted at the U.S. Geological Survey Marine Field Station on Marrowstone

Island, Washington. Results from the first set of studies of the system showed that

hypochlorite levels greater than 3.0 ppm hypochlorite with or without filtration reduced

bacteria by more than 99.999%, reduced phytoplankton by more than 99%, and

reduced mesozooplankton by more than 99%. Filtration improved efficacy only when

hypochlorite concentration was initially less than 1.5 ppm.

1. Introduction

1.1 Regulations

THE MARINE ENVIRONMENT PROTECTION COMMITTEE (MEPC) of

the International Maritime Organization met in February 2004.

The committee adopted a new world Ballast Water Convention

that will enter into force 12 months after ratification by 30 member

states representing 35% of the world’s gross tonnage. The Con-

vention is divided into articles and, more importantly for the de-

velopment of ballast water treatment technologies, an annex that

includes technical standards and requirements in the regulations

for the control and management of ship ballast. All ships, includ-

ing submersibles, floating craft, floating storage units (FSUs), and

floating production, storage, and offloading units (FPSOs), are to

manage their ballast water in accordance with an approved ballast

water management plan and record such management in a ballast

water record book. All ships greater than or equal to 400 gt are to

be surveyed (initial, annual intermediate, and renewal) and

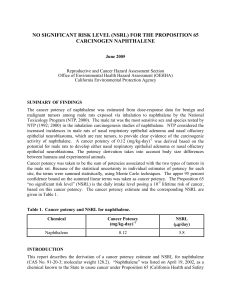

certificated (not exceeding 5 years). Table 1 summarizes the

implementation schedule of the type of treatment required accord-

ing to the age of ship and its ballast capacity as per the provi-

sions of the Convention (International Maritime Organization

2004).

Indicator microbe concentrations shall not exceed:

• Toxicogenic Vibrio cholerae: 1 colony forming unit (cfu)

per 100 ml

•Escherichia coli: 250 cfu per 100 ml

• Intestinal Enterococci: 100 cfu per 100 ml.

Ballast water exchange is to take place as follows:

• At least 200 nautical miles from the nearest land and 200

m water depth OR

• In the event throughout the intended route the sea area

does not afford the above characteristics, in a sea area desig-

nated by the port state. There may be a need to alter the ship’s

intended route to exchange ballast in the designated area.

States may establish additional ballast water management mea-

sures for ships to meet based on guidelines, which remain to be

Presented at the 2005 Ship Production Symposium, Society of Naval Ar-

chitects and Marine Engineers, October 19 to 21, Houston, Texas.

Journal of Ship Production, Vol. 22, No. 3, August 2006, pp. 160–171

160 AUGUST 2006 8756/1417/06/2203-0160$00.49/0 JOURNAL OF SHIP PRODUCTION

developed. The MEPC shall undertake a review of the Ballast

Water Standards no later than 2006 and is to include an assessment

of the technologies available that achieve the standard. As part of

the assessment, the MEPC requires significant documentation of

the system, with efficacy data for both land-based and shipboard

tests. Criteria for such testing have been established and outlined

in MEPC document MEPC 52/WP.7 titled “Guidelines for Ap-

proval of Ballast Water Management Systems.”

As a result of these regulations, there is a need for a proven,

viable, cost-effective ballast water treatment system by 2007. This

will allow ship designers to specify and incorporate such devices

into ships that begin construction after January 1, 2009. This paper

is the summary of land-based work on a ballast water treatment

(BWT) system utilizing on-site hypochlorite generation.

1.2. Ballast water management strategies

1.2.1. Open-ocean ballast water exchange. Most environmental

scientists agree that ballast water that is exchanged in the open

seas presents less of an ecological threat or risk to the receiving

waters. The question is whether the threat has been reduced to an

acceptable level. As presently engineered and practiced, reballast-

ing does not exchange 100% of the ballast water or remove all of

the sediments that are found in ballast water tanks. The amount of

the exchange varies from ship to ship. Older ships tend to ex-

change less efficiently than newer ships. Dickman and Zhang

(1999) examined four containerships that took on ballast in

Mexico and discharged 21 days later in Hong Kong. After this

period, few of the dinoflagellate and diatom species taken on in

Mexico were alive in the ballast water in Hong Kong. Five ships

that reballasted in the open ocean reduced the diatom and dino-

flagellate populations by 48%. They concluded from results of this

and previous study that older vessels were less effective in remov-

ing diatom and dinoflagellate species than newer ships. The reason

could be that the reballasting design of older ships was less effi-

cient in removing water and sediments located near the bottom of

the ballast tanks and that the bottom water is associated with a

large number of resting cysts and cells. Ships sampled in Puget

Sound by the University of Washington’s ballast water team

showed that even in ships that reported open ocean exchange, up

to 50% of the organisms were nonnative to the northeastern Pa-

cific.

1.2.2. Ballast water treatment technologies. A variety of treat-

ment technologies are suggested for the removal or reduction of

organisms that are found in ballast water. The challenge is to

develop a technology that is effective against a variety of biologi-

cal taxa and that is capable of quickly treating the very large

volumes of ballast water that are associated with large ships.

Treatment technologies may be developed for on-board or at-port

applications. Technologies that have received most of the recent

consideration include (1) cyclonic separation, (2) heat treatment,

(3) electric pulse, (4) ultraviolet light, (5) filtration, and (6) bio-

cides. These technologies were listed and reviewed in the National

Research Council publication “Stemming the Tide: Controlling

Introductions of Nonindigenous Species by Ships’Ballast Water”

(National Research Council 1996). We briefly review the pro-

posed technologies and provide some comment.

Cyclonic separation. A more sophisticated and more recently

developed technology involves cyclonic separation. This is nor-

mally accomplished using hydrocyclones. If properly designed

and applied, hydrocyclones will require less pump pressure than

screen filters and will allow separation of sediments and other

suspended solids to approximately 20 µm. Hydrocyclones are lim-

ited, however, to separating solids with a specific gravity greater

than, or less than, water. Many types of organisms (e.g., bacteria

and other microorganisms) will not be separated from the water

since their specific gravity is extremely close to seawater.

Ultraviolet light. In close contact, ultraviolet (UV) light treat-

ment is effective in killing non–spore-forming microorganisms. It

does not appear effective in inactivating higher organisms or the

cyst or resting stages of protozoa. Ultraviolet light was not effec-

tive in totally eliminating dinoflagellates. Montani et al. (1995)

found that after exposure to ultraviolet light for 2 hours, the ger-

mination of Chattonella sp. cysts decreased to 6% of the control,

whereas germination of cysts of other species of dinoflagellates

(Alexandrium sp. and Gymnodinium sp.) was more than 40% of

the controls. The University of Washington research team has

performed controlled mesocosm tests at the Marrowstone Marine

Field Station in which Puget Sound seawater was amended with

additional zooplankton. The amended seawater was exposed to

moderate levels of UV light. They found that zooplankton mor-

tality was delayed and did not immediately occur. The microbial

populations were quickly reduced in number following exposure

to the UV light but rebounded to their original levels within a few

days.

Heat treatment. The use of waste heat from the ship’s propul-

sion and service cooling is an attractive option for the inactivation

of organisms in ballast water. No chemical byproducts or residuals

Table 1 Ballast water treatment implementation schedule

Ballast Capacity (m

3

) Construction Date 2009 2010 2011 2012 2013 2014 2015 2016 2017

<1,500 <2009 D1 or D2 D2

>2009 D2

>1,500 <2009 D1 or D2 D2

<5,000 >2009 D2

>5,000 <2012 D1 or D2

>2012 D2

D1 ⳱ballast water exchange (95% volumetric exchange) or pumping through three times the volume of each tank.

D2 ⳱ballast water treatment systems approved by the Administration with treatment efficacy of:

+ Not more than 10 viable organisms per m

3

>50 m.

+ Not more than 10 viable organisms per milliliter >10 and <50 m.

AUGUST 2006 JOURNAL OF SHIP PRODUCTION 161

would be associated with the discharge of heat-treated ballast

water. A number of factors will limit the practicality of thermal

treatment primarily related to the volume of water that is associ-

ated with large vessels and the amount of energy required to heat

the volume. Thermal treatment may be more applicable to ballast

water originating from warmer environments. Heat required for

thermal treatment could be reduced where water temperatures are

at tropical or summer levels (30 deg C or higher). The heat loss to

the ambient waters outside of the hull must be considered. Dif-

ferent types of organisms or organisms from different parts of the

world may have different sensitivities to heat. A few recent studies

suggest that heating ballast water is the best method for killing a

variety of higher organisms and microorganisms that are found in

ballast water. Rigby et al. (1999) showed how a cost-effective

heating technique using waste heat from a ship engine could be

used to kill many unwanted organisms. In an ocean trial, heated

water flushed through one of the ballast tanks resulted in the

destruction of all zooplankton with very limited survival of the

original phytoplankton.

Electric pulse. Small-scale experiments have been performed

by applying electrical voltages in the 15 to 45 kV range with pulse

duration of 1 µs. Large energy sources would be required for

systems capable of treating large volumes of ballast water (Na-

tional Research Council 1996).

Filtration. The physical separation and removal of organisms

can be accomplished during ballasting operations using a ship-

board filtration system. Some would argue that this technology is

the most promising choice. Filtering ballast water as it is loaded is

an attractive option since it would minimize the introduction of

unwanted organisms. The options for onboard filtration systems

are either mesh strainers or deep media filtration. Many problems

associated with a strainer technology have been solved with the

development of commercially available continuously cleaned

screening systems. Media filters are attractive in principal because

small-size particles can be removed, but these filters are most

likely unrealistic for on-board treatment of ballast water because

of the large footprint that would be required. The primary disad-

vantage of the strainer filters is that many organisms are smaller

than strainers and would pass through the treatment system. A

study for the Canadian Coast Guard (1992) concluded that the

physical removal of organisms by filtering may be an effective

stand-alone treatment process or may be used in conjunction with

other technologies, such as chemical treatment or UV sterilization.

Flow-through centrifugation systems can separate particles prior

to filtering to reduce filter clogging.

Biocides. The addition of chemicals that would kill or inactivate

a variety of organisms found in ballast water is an attractive treat-

ment technology because of the ease of application. A biocide

could simply be added to the ballast tank and allowed to react for

a specified period. Biocides are among the most widely used in-

dustrial chemicals, and there is a large body of knowledge about

their use in wastewater treatment. If similar concentrations were

required to inactivate organisms found in ballast water, then a

large ship would need to carry only a few cubic meters of biocide

per voyage. The use of biocides for ballast water treatment has

been rejected by some for several reasons, including the reluctance

to add toxic chemicals to water that may be discharged back into

the ocean, the unknown effectiveness of biocides against target

organisms, and compliance with discharge regulations around the

world. Oxidizing biocides such as chlorine, chlorine salts, and

ozone have been used for decades in a variety of sanitizing appli-

cations. Ozone is a strong oxidizing agent used for treatment of

potable and industrial waters. With the increasing environmental

concern associated with the use of chlorine, ozone has received

greater attention in recent years. Ozone is an unstable gas that

must be generated as needed, and some reviewers have concluded

that ozone may not be practical for shipboard use (National Re-

search Council 1996). Along with generation, ozone efficacy is a

problem due to the gas–liquid contact requiring elaborate diffu-

sion equipment. In salt water, ozone produces many of the similar

residual compounds as chlorination. Nonoxidizing biocides such

as glutaraldehyde or vitamin K have also have been suggested.

2. Electrochlorination

2.1. Background

Seawater (normally between 15 and 35 grams/liter) or other

water containing NaCl may be used to generate a disinfecting

solution containing chlorine by passing a direct electrical current

through the solution. On-site generation of hypochlorite from sea-

water has been used for over 25 years. These systems can be

purchased as completely skid-mounted systems that generate so-

dium hypochlorite from seawater. These systems are used in re-

fining, petrochemical power plants, offshore drilling production,

and marine applications around the world. Systems can be scaled

to the appropriate size depending on the quantity of hypochlorite

required.

The type of electrolytic cell commonly used in these marine and

offshore applications is a “tube within a tube.”A cell consists of

one anode, one cathode, and one bipolar tube with the necessary

ancillary hardware to facilitate assembly. The outer anode and

cathode are manufactured from seamless titanium pipe. The anode

surface is coated with proprietary precious metal oxides, primarily

ruthenium and iridium. Seawater enters one end of the cell and

passes between the cathode, the anode, and bipolar tube annular

spaces. When direct current is applied to the cell, sodium hypo-

chlorite results. One cell can produce up to 5.5 kg/day, and a

maximum of 12 cells can be connected in series for a capacity of

65 kg/day per train.

In some applications, such as ballast water treatment, a dechlo-

rination step can be added to the process. This requires adding a

reducing agent, such as sodium sulfite, to the end of the system to

neutralize any residual chlorine at the point of discharge. The end

result is a nontoxic stream with no free chlorine.

2.2. Chemistry

The process is based on the partial electrolysis of NaCl present

in seawater as it flows through an unseparated electrolytic cell.

The resulting solution exiting the cell is a mixture of seawater,

sodium hypochlorite (hypo), hydrogen gas, and hypochlorous

acid. Electrolysis of sodium chloride solution (seawater in this

study) is the passage of direct current between an anode (positive

pole) and a cathode (negative pole) to separate salt and water into

their basic elements. Chlorine generated at the anode immediately

goes through chemical reactions to form sodium hypochlorite and

hypochlorous acid. Reactions are shown below:

Cl

−

→Cl

2

(aq) + 2e

−

Eo ⳱1.396 V (1)

162 AUGUST 2006 JOURNAL OF SHIP PRODUCTION

which is hydrolyzed in solution to form hypochlorous acid:

Cl

2

+2H

2

O→2HOCl + 2H

+

(2)

Hypochlorous acid dissociates to hypochlorite at alkaline pH levels:

HOCl →OCl

−

+H

+

pKa =7.5 (3)

In seawater bromide ions are present, together with a range of

inorganic cations as well as possibly ammonia and a variety of

organic compounds. The reaction of molecular chlorine or hypo-

chlorite ions with ammonia or amino compounds leads to the

disinfectants, and they react to destroy bacteria and microorgan-

isms in the water just as do chlorine, hypochlorous acid, and

hypochlorite ions. The rapid oxidation of bromide ions will also

occur and (as with chlorine) in the aqueous environment form

hypobromous acid (HOBr) and hypobromite ions (OBr

−

). These

reactions will also be equilibrium processes, dependent on tem-

perature and pH. Note also that brominated species will react with

ammonia and/or amino compounds if present in the water, just like

the chlorine analogues.

Hydrogen and hydroxides are formed at the cathode, the hy-

drogen forms a gas and is vented, and the hydroxide aids in the

formation of sodium hypobromite and increases the exit stream pH

to approximately 8.5. This reaction is shown as follows:

2H

2

O+2e

−

→H

2

(g) +2OH

−

Eo =−0.828 V (4)

Because the electrolytic cell used for this application is unsepa-

rated, the reactants at both anode and cathode can further react to

form the respective end products shown in the overall electro-

chemical and chemical reaction as follows:

NaCl +H

+

+Br

−

+2e →NaOBr +H

2

+Cl

−

Salt +Water +Energy →Sodium Hypochlorite +Hydrogen

(5)

2.3. Disinfection by-products

Disinfecting agents, such as chlorine, ozone, chlorine dioxide,

and chloramines, react with natural organic material present in

water to produce disinfection by-products (DBPs). Most of the

research and interest in DBPs has been with drinking water. DBPs

have been known since 1974, when chloroform was identified as

DBP resulting from the chlorination of tap water. Since then,

hundreds of DBPs have been identified in drinking water. The

benefit of disinfecting drinking water is obvious, as thousands of

people died from waterborne disease before municipalities began

to disinfect drinking water, but it is also generally recognized that

it is important to minimize the formation of DBPs in drinking

water. Several DBPs have been linked to cancer in laboratory

animals, and as a result, the US Environmental Protection Agency

(EPA) has regulated some DBPs.

While we anticipate that most people will not be drinking bal-

last water and other treated seawater, we have evaluated the for-

mation of selected DBPs that may be formed following the gen-

eration of hypochlorite in seawater. Seawater is significantly

different from freshwater, not just because of the relatively high

concentration of Na

+

and Cl

-

and oftentimes higher levels of natu-

ral organic material, but also because of the presence of Br

−

(bro-

mide). The presence of this ion may lead to the formation of

bromate (BrO

3

−

), a compound that is considered a possible human

carcinogen. In the United States, bromate is regulated at 10 µg/L

(10 parts per billion) in drinking water. Seawater contains a typical

bromide concentration of 65 mg/L, so the concentration in sea-

water is significant. Therefore, bromate was one of the DBPs

measured in our research. In addition, the presence of haloacetic

acids (HAAs) and trihalomethanes (THMs) are a concern and

were measured as part of the overall study.

One other component of the ballast water treatment system is

the neutralization of the free halogen (hypochlorite and hypobro-

mite) prior to discharge from the ballast tanks. Sodium sulfite is

used, and the simplified reaction is shown below to form sodium

sulfate. As shown in the equation, neutralization occurs at one to

one molar ratio but two to one (sulfite to halogen) as a weight

ratio.

Na

2

SO

3

+Cl

2

+H

2

O–>Na

2

SO

4

+2HCl

Sodium Sulfite +Chlorine +Water –> Sodium Sulfate

+Hydrochloric Acid (6)

Typically, there are 4 g/L sulfate in seawater, and based on the

concentrations of halogen required, only 10 mg of sulfate will be

added to the discharge ballast water. Also, the amount of HCl

generated is negligible and will not change the pH of the discharge

ballast water.

3. Pilot electrochlorination ballast water treatment

3.1. Background

The University of Washington School of Aquatic and Fishery

Sciences performed third-party verification tests on the Severn

Trent DeNora’s Electrochlorination Ballast Water Treatment

(BWT) System (BalPure; Severn Trent DeNora, Sugar Land, TX).

The pilot plant system consisted of two 5.7 m

3

(1,500 gallon) raw

seawater holding tanks. The water was pumped through a 50-m

self-cleaning filter. When the pressure drop reached a preset value,

the filter was automatically back flushed while continuing to op-

erate. A stream volume of roughly 10% of the inlet flow to the

filter was generated, containing the removed organisms and solid

contaminants. During a ballast water operation, this stream would

be discharged overboard. For purposes of this test, the stream was

collected.

After the water was filtered, a side stream was fed to the elec-

trolytic cell, where oxidizers were generated. This oxidized stream

was then injected and mixed with the main stream. After the

hypochlorite stream was mixed with the mainstream, the water

was sampled and the free halogens were measured and recorded.

This on-line real-time free halogen value was used to automati-

cally adjust the amount of hypochlorite generated for the ballast

water treatment. Based on previous lab tests, the expected required

dosage after filtration ranged from 1 ppm up to 5 ppm.

Once the water was treated, it was placed in replicate dark

mesocosms. This step was analogous to ballast water in ballast

tank conditions. After 7 to 14 days of storage, the seawater was

monitored before it was “discharged.”A dehalogenation agent,

such as sodium sulfite, was injected into the water to react or

neutralize any free halogens. A schematic of the pilot process is

shown in Fig. 1.

AUGUST 2006 JOURNAL OF SHIP PRODUCTION 163

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

1

/

13

100%