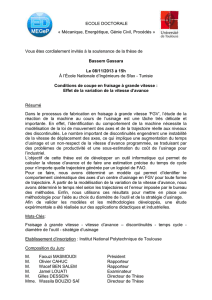

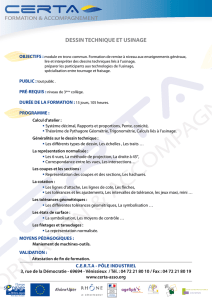

!

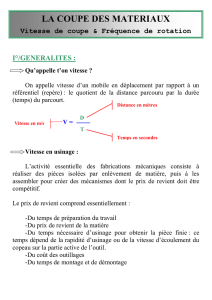

F!"#$%&$%C'(()!**)("$*%

+(,-.$/$(0%&$%/)0!-1$%2%31)!*)4$%

Innovation'Technologique'et'Eco'Conception%'

%

%

Ressources(Usinage(par(enlèvement(de(matière(:(Fraisage(Page(1(

%

56usinage%7)1%$(,-.$/$(0%&$%/)0!-1$%$*0%8(%71'"9&9%&$%:);1!")0!'(%&$%7!-"$*%/9")(!<8$*=%%

Principe%:%

+(,$.$1% &$% ,)% /)0!-1$% &$% :)>'(% ?% &'(($1% ?% ,)% 7!-"$% ;180$% ,)% :'1/$% $0% ,$*% &!/$(*!'(*% .'8,8$*@% ?%

,6)!&$%&68($%/)"#!($A'80!,=%B)1%"$00$%0$"#(!<8$@%'(%';0!$(0%&$*%7!-"$*%&68($%41)(&$%719"!*!'(=%

%

C,%$D!*0$%7,8*!$81*%71'"9&9*%&E8*!()4$@%('0)//$(0%2%

• 5$*%usinages%par%déformation%2%:'14$)4$@%0#$1/':'1/)4$@%7,!)4$%

• 5$*%usinages%par%découpage%2%&9"'87$%,)*$1@%'DF"'87)4$@%

• $0%$(:!(%,$*%usinages%par%enlèvement%de%matière%2%0'81()4$@%:1)!*)4$@%9,$"01'91'*!'(=%

%

G'8*%),,'(*%('8*%!(091$**$1%7,8*%7)10!"8,!-1$/$(0%)8%:1)!*)4$=%

A. La relation Outil / Machine / Pièce :

H(%,E)%.8@%8*!($1%"'(*!*0$%?%/'&!:!$1%,)%:'1/$%&E8($%pièce%7)1%,E)"0!'(%&E8($%machine@%)8%/'F$(%

&E8(%outillage=%I'("%0'80%8*!()4$%/$0%$(%1$,)0!'(%"$*%01'!*%9,9/$(0*%2%

• 5E'80!,@%

• 5)%/)"#!($@%

• 5)%7!-"$%

H(%7$80%*"#9/)0!*$1%,)%1$,)0!'(%&$%,)%/)(!-1$%*8!.)(0$%2%

%

5)%7!-"$%$0%,E'80!,%*'(0%:!D9*%*81%,)%/)"#!($%41J"$%)8%7'10$A7!-"$%$0%)8%7'10$A'80!,=%

%

K8!.)(0% ,$*% "#)L($*% 1$,)0!'(($,,$*% M%H80!,% N% O)"#!($% N% B!-"$%P% $0% ,$% 1$7-1$% &6)D$*% &)(*% ,$<8$,%

*6!(*"1!.$(0% ,$*% &!::91$(0*% &97,)"$/$(0*@% ,$*% 71!("!7$*% &68*!()4$% /!*% $(% Q8.1$% .)1!$(0% $0%

&9:!(!**$(0%)!(*!%différents%types%d'usinages!R7)1%$(,-.$/$(0%&$%/)0!-1$S=%

%

B'10$A'80!,%

Outil

B'10$%7!-"$%

Pièce

LIAISONS MACHINES

%

%

O9")(!<8$*%2%;J0!@%48!&)4$*@%"!(9/)0!<8$%

RTF7','4!$%&$*%/)"#!($*S%

%

+,$"01!<8$*%2%/'0$81*@%.)1!)0$81*%

%

+,$"01'(!<8$*%2%)80'/)0$%

RU9*$)8D%$0%09,9"#)14$/$(0S%

%

C(:'1/)0!<8$*%2%,)(4)4$@%"F",$*%

RB1'41)//)0!'(S%

Ressources(Usinage(par(enlèvement(de(matière(:(Fraisage((Page(2(

%

B. Les mouvements :

B'81%8*!($1@%,E'80!,%&'!0%*$%&97,)"$1%7)1%1)77'10%?%,)%7!-"$=%VE$*0%,)%/)"#!($%<8!%*$%"#)14$%&E)**81$1%

,)%;'(($%"''1&!()0!'(%$(01$%,$*%.!0$**$*%$0%,$*%01)W$"0'!1$*%&$%,E'80!,%$0%&$%,)%7!-"$=%

%

T'80%/'8.$/$(0%&E8(%9,9/$(0%&E8($%/)"#!($A'80!,%ROHS%*E!(*"1!0%&)(*%8(%1$7-1$%

'10#'('1/9%?%01'!*%&!/$(*!'(*=%

C,%$*0%*!/7,$%&E80!,!*$1%,)%1-4,$%&$*%01'!*%&'!40*%&$%,)%/)!(%&1'!0$%

%

%

+(%:1)!*)4$%,E'80!,%0'81($%)80'81%&E8(%)D$%$0%,)%7!-"$%*$%&97,)"$=%

K81% "$10)!($% /)"#!($% ,$*% &$8D% 7$8.$(0% *$% &97,)"$1% *81% 8(% )D$% '8% 0'81($1%

)80'81%&E8(%)801$%)D$=%

%

5$*%01'!*%)D$*%&$%,E$*7)"$%*'(0%)77$,9*%"'81)//$(0%2%X@%Y%$0%Z=%

%

%

H(%&!*0!(48$%[%0F7$*%&$%/'8.$/$(0%2%

1.

Le mouvement de coupe

C,%7$1/$0%?%,E'80!,%&$%"'87$1%,)%7!-"$%&)(*%,)%\'($%&$%"'(0)"0%'80!,%

N%7!-"$=%C,%$*0%('09%Mc=%%

%

+(%:1)!*)4$@%"E$*0%,E'80!,%<8!%$*0%)(!/9$%&8%/'8.$/$(0%&$%"'87$=%

C’est%généralement%une%rotation.%%

5)%.!0$**$%)**'"!9$%?%O"%$*0%,)%vitesse!de!coupe@%('09$%Vc=%]"%$*0%

49(91),$/$(0%41)(&=%

%

2.

Le mouvement d’avance

C,%7$1/$0%?%,E'80!,% &$%*$% &97,)"$1%,$% ,'(4%&$% ,)%7!-"$=% C,%$*0% ('09%

Mf.%

%

+(% :1)!*)4$@% "E$*0% ,)% 7!-"$% <8!% $*0% )(!/9$% &8% /'8.$/$(0%

&E).)("$=%Le%mouvement%d’avance%est%généralement%une%translation.%%

%

5)%.!0$**$%)**'"!9$%?%O:%$*0%,)%.!0$**$%&E).)("$@%('09$%Vf=%]:%$*0%49(91),$/$(0%;$)8"'87%7,8*%7$0!0%

<8$%]"=%

%

C. La pièce :

5$*% 7!-"$*% 8*!(9$*% $(% :1)!*)4$% *'(0% 49(91),$/$(0% &$% :'1/$% 71!*/)0!<8$@% "E$*0% ?% &!1$% 8(% .',8/$%

&9,!/!09%7)1%&$*%:)"$*%7,)($*=%O)!*%'(%7$80%)8**!%19),!*$1%&E)801$*%:'1/$*%2%

• &$*%"F,!(&1$*%R&$*%7$1>)4$*%$0%&$*%),9*)4$*S%

• &$*%*81:)"$*%#9,!"'^&),$*%R&$*%.!*S%

• $(:!(@%&$*%:'1/$*%"'/7,$D$*@%"19$*%7)1%8($%01)W$"0'!1$%&9:!(!$%&$%,E'80!,=%

%

+(%:1)!*)4$@%,$*%:'1/$*%8*!(9$*%*'(0%01-*%.)1!9$*=%

Ressources(Usinage(par(enlèvement(de(matière(:(Fraisage((Page(3(

%

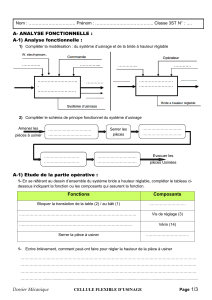

D. Les machines-outils

%

1.

La machine conventionnelle

_%

`J0!%

a%

B!-"$%

[%

Tb0$%

c%

V#)1!'0%,'(4!08&!(),%

d%

`1'"#$%

e%

V#)1!'0%01)(*.$1*),%

f%

H80!,%R:1)!*$S%

g%

V#)1!'0%.$10!"),%

%

%

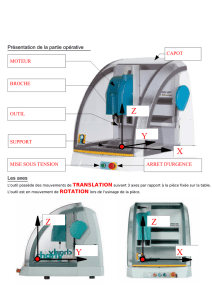

2.

MOCN

h($% O)"#!($AH80!,% ?% V'//)(&$% G8/91!<8$% :'("0!'(($% &$% /)(!-1$%

)80'/)0!<8$=%%

%

a) Les différents éléments :

5$*% actionneurs% R/'0$81*@% .91!(*@===S% *'(0% "'//)(&9*% 7)1% 8(%

71'"$**$81% Rdirecteur! de! commande! numériqueS=% V$,8!A"!% *)!0%

$D7,'!0$1%$0%!(0$17190$1%,$*%!(:'1/)0!'(*%&'((9$*%7)1%,$%71'41)//$%&E8*!()4$%'8%7)1%,$*%capteurs!

de!mesure=%%

5$%pupitre!de!commande%*$10%?%"'(.$1*$1%%).$"%,$%&!1$"0$81%&$%"'//)(&$=%CC%7'**-&$%&$*%0'8"#$*%

*$(*!0!.$*@% )!(*!% <868(% 9"1)(% 41)7#!<8$=% V$,8!A"!% *$10% ?% .!*8),!*$1% 7)1% $D$/7,$% ,$% 71'41)//$@% ,$%

71':!,%:!(!%&$%,)%7!-"$@%,)%01)W$"0'!1$%&$*%'80!,*@%===%

5)% tourelle! porte<outils% 7$1/$0% &$% "#)(4$1% &E'80!,% ):!(% &$% 19),!*$1% 0'80$*% ,$*% '791)0!'(*% &E8($%

7#)*$%&E8*!()4$=%

%

b) Les axes normalisés

VE$*0%,)%&!1$"0!'(%*8!.)(0%,)<8$,,$%,$%/'8.$/$(0%$*0%"'//)(&9%(8/91!<8$/$(0%$(%"'(0!(8%

$(%.!0$**$%$0%7'*!0!'(=%%

%

5E)D$%Z%%$*0%*!089%7)1),,-,$/$(0%?%,E)D$%&$%,)%;1'"#$%71!("!7),$%<8$,,$%<8$%*'!0%,)%/)"#!($%%

5E)D$%X%$*0%)**'"!9%)8%/'8.$/$(0%<8!%&9:!(!%,$%7,8*%41)(&%&97,)"$/$(0%)71-*%).'!1%*!089%%

,E)D$%Z=%%

5E)D$%Y%:'1/$%).$"%,$*%)D$*%X%$0%Z%8(%01!-&1$%&$%*$(*%&!1$"0=%%

%

5$*% "'(*018"0$81*% &$% OHVG% '(0% "'(>8% &$*% :1)!*$8*$*% ).$"% "$*% )D$*%

*877,9/$(0)!1$*%2%iD$%&$%1'0)0!'(%&9:!(!%)80'81%&$*%)D$*%71!("!7)8D=%

%

%5$% *"#9/)% "!A"'(01$% "'11$*7'(&% ?% 8($% :1)!*$8*$% a%

)D$*%2%,$%f9/$%)D$%V%"'11$*7'(&%?%,)%0);,$%0'81()(0$%'8%7,)0$)8%"!1"8,)!1$=%K'(%

/'8.$/$(0%&$%1'0)0!'(%7$1/$0%,E8*!()4$%&$%7!-"$*%*)(*%&9/'(0)4$%*81%dcjk=%

5$%a9/$%)D$%i%"'11$*7'(&%?%,)%1'0)0!'(%&$%,)%;1'"#$%)80'81%&$%X=%

V$%0F7$%&$%:1)!*$8*$%$*0%7)1:)!0$/$(0%)&)709%?%C%l8*!()4$%&$%7!-"$*%"'/7,$D$*=%

C,%$*0%7'**!;,$%&$%1)W'80$1%7)1%$D$/7,$%8(%)801$%)D$%i%R,)%7!-"$%)80'81%&$%XS@%

8(%)D$%`@%===%2%'(%7$80%7)1:'!*%01'8.$1%&$*%/)"#!($*%m%)D$*%$0%/b/$%7,8*===%

%

Ressources(Usinage(par(enlèvement(de(matière(:(Fraisage((Page(4(

%

Z!

Y!

X!

c) Le positionnement de la pièce dans la machine

C,%$*0%(9"$**)!1$%&$%7'*!0!'(($1%,6$D019/!09%&$%,6'80!,%R7'!(0%"'81)(0S%7)1%1)77'10%?%,)%7!-"$=%

%

Origine%programme%:%OP%

B'81% 9"1!1$% 8(% 71'41)//$@% !,% $*0% "'//'&$% &$% :!D$1% 8(% 1$7-1$% *81% ,)% 7!-"$% ?% 7)10!1% &8<8$,% '(%

"),"8,$%,$*%"''1&'((9$*%&$*%7'!(0*%2%VE$*0%,E'1!4!($%71'41)//$%HB=% %

V$00$%HB%$*0%"#'!*!$%7)1%,$%71'41)//$81%"#)149%&$%7197)1$1%,)%71'&8"0!'(=%

Origine%pièce%:%Op%

5E'1&!()0$81%)%;$*'!(%&$%"'(()L01$%,)%7'*!0!'(%&$%,)%7!-"$@%!//';!,!*9$%*81%,)%0);,$%&$%,)%/)"#!($=%

VE$*0%7'81<8'!@%'(%&9:!(!0%*81%,$%:!"#!$1%&E8*!()4$@%8(%7'!(0%&E'1!4!($%7!-"$=%

VE$*0%,E'1!4!($%&8%1$7-1$%&$%/!*$%$(%7'*!0!'(%&$%,)%7!-"$%*81%,$%7'10$A7!-"$=%n8)(&%'(%"#)(4$%&$%

7!-"$@%,EH7%($%;'84$%7)*%*!%$,,$%$*0%7'*!0!'((9$%)8%/b/$%$(&1'!0%*81%,)%/)"#!($=%

%

+(%:1)!*)4$@%).$"%8(%90)8@%,EH7%$*0%*!089%2%

• +(%Z%2%*81%,$*%"),$*%&$%:1)!*)4$=%

• +(%X%2%"'(01$%,)%;809$@%

• +(%Y%2%"'(01$%,$%/'1*%:!D$@%

%

K!%'(%($%&9:!(!0%7)*%,6'1!4!($%7!-"$%).)(0%&$%&9/)11$1%

,68*!()4$@%,)%/)"#!($%19),!*$%,68*!()4$%/)!*%$,,$%démarre

n'importe où.

%

%

Origine%mesure%:%Om%

5)%/)"#!($%"'(01o,$%*$*%&97,)"$/$(0*%?%7)10!1%&68($%'1!4!($%);*',8$@%&'(0%,)%7'*!0!'(%$*0%&9:!(!$%

7)1%,$%"'(*018"0$81@%%)77$,9$%HUCpCG+%O+KhU+%2%H/=%

VE$*0%,$%M%7'!(0%\91'%P%&$%,)%/)"#!($@%?%7)10!1% &8<8$,%$,,$% "),"8,$%0'80$*% ,$*%)801$*% "''1&'((9$*=%

+,,$%$*0%1$719*$(09$%7)1%,$%*F/;',$%2%%

%H/%

%

Origine%tourelle%:%Ot%(ou%point%de%Référence%outil)%

h($%OHVG%80!,!*$%1948,!-1$/$(0%7,8*!$81*%'80!,*%&$%"'87$%&$%&!/$(*!'(*%&!::91$(0$*% $0%&'("%&$%

7'!(0*%&$%"'87$%&!::91$(0*=%K!%,$*%'80!,*%"#)(4$(0@%,$*%7'10$A'80!,*@%$(%1$.)("#$@%1$*0$(0%,$*%/b/$*=%

%

5E'1!4!($%0'81$,,$%$*0%),'1*%,$%7'!(0%")1)"091!*0!<8$%&$%,)%,!)!*'(%$(")*01$/$(0%$(01$%

,$%7'10$A'80!,%$0%,)%0'81$,,$%R'8%,)%;1'"#$%$(%:1)!*)4$S=%VE$*0%8(%7'!(0%!(.)1!)(0%<8!%

($%&97$(&%7)*%&$%,6'80!,=%

H0%$*0%94),$/$(0%,E'1!4!($%&8%7'10$A'80!,@%<8$%,E'(%:!D$%*81%,)%0'81$,,$=%

%

+(%:1)!*)4$%2%,$%"$(01$%&$%,6)D$%&$%1'0)0!'(%&$%,)%;1'"#$%*81%,)%:)"$%).)(0%&8%"o($%

&6)00)"#$/$(0=%

%

%

Ressources(Usinage(par(enlèvement(de(matière(:(Fraisage((Page(5(

%

Gk%

&E'80!,%

Gk%

"'11$"0$81%

&E'80!,%

q)84$*%

r%

RV'11$"0$81%

&F()/!<8$S

%

5%

U%

T[%

I[%

_j_=[[%

_=a_%

j%

%

3.

Le point courant : T

K81% 8($% OHVG% ,$% 7'!(0% 19$,% ?% 7!,'0$1% $*0% ,$% 7'!(0% &$% "'87$% &$% ,6'80!,=% V$%

7'!(0%*$%&97,)"$%*81%,)%7!-"$%*$,'(%,)%71'41)//)0!'(%90);,!$%&)(*%,$%1$7-1$%

/)"#!($%):!(%&E8*!($1%,)%7!-"$=%

%

5)%W)84$%'80!,%7$1/$0%&$%&9:!(!1%,$%7'!(0%&$%"'87$%&$%,E'80!,=%

V$%.$"0$81% ")1)"091!*$%,)% &!/$(*!'(%&$% ,E'80!,=%C,%"#)(4$% ?%"#)<8$% :'!*%<8$%

,E'(%"#)(4$%&E'80!,=%%

C,%:)80%!(&!<8$1%"$*%.),$81*%&)(*%,$%&!1$"0$81%&$%"'//)(&$%(8/91!<8$=%%

i% "#)<8$% '80!,% 80!,!*9% "'11$*7'(&% *)% W)84$=% I-*%

<8E'(% "#)(4$% &E'80!,@% ,$% 71'41)//$% &'!0% :)!1$%

)77$,%?%,)%W)84$%"'11$*7'(&)(0%?%,E'80!,=%

%

T% $*0% 7)1:'!*% )77$,9% ,$% 7'!(0% "'81)(0%

M%B0"'81%P=%

%

E. Le porte-pièce :

+(%49(91),@%'(%80!,!*$%8(%90)8@%:!D9%*81%,)%0);,$=%C,%7$1/$0%&$%*$11$1%8($%

7!-"$%$(01$%[%:)"$*%7)1),,-,$*=%%

V$0%90)8%$*0%'1!$(0);,$@%&$%:)>'(%?%7,)"$1%,)%7!-"$%$(%01).$1*%&$%,)%0);,$=%

%

O)!*% ,'1*<8$% ,)% 7!-"$% $*0% &$% :'1/$% "'/7,$D$@% '8% <8$% ,E'(% &9*!1$% 8($% /!*$% $(%

7'*!0!'(%7)10!"8,!-1$@%'(%7$80%80!,!*$1%8(%/'(0)4$%&E8*!()4$%2%

%

H(%7$80%)8**!%:!D$1%,)%7!-"$%&!1$"0$/$(0%*81%,)%0);,$=%

%

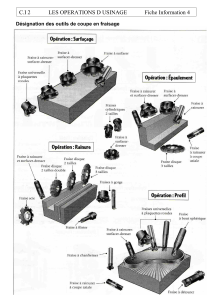

F. Les opérations d’usinage

%

K81:)>)4$%

+7)8,$/$(0%

U)!(81)4$%

V'(0'81()4$%

%

%

%

%

B'!(0)4$%

B$1>)4$%

i,9*)4$%

%

%

%

+4),$/$(0%7'81%8*!($1%&$*%

01'8*@%/)!*%,$%71'"9&9%$*0%

&!::91$(0%")1%&)(*%"$%")*@%

'(%"#$1"#$%?%';0$(!1%&$*%

01'8*%719"!*%R&$*%),9*)4$*S%

%

%

%

L!

R!

6

6

7

7

8

8

1

/

8

100%