GAS INSULATED SUBSTATION & SWITCHGEAR

Asif Eqbal: Electrical & Electronics

Engineer

1. Introduction and governing standard

2. Conventional substation (AIS)

3. Limitation of AIS

4. Need for GIS

5. Introduction to GIS

6. Service condition of GIS as per IEEE

7. Services offered by GIS user & GIS supplier

8. Technical requirements & design features

9. Maintenance philosophy of GIS switchgear

10. Comparison of GIS and AIS substation

11. Drawbacks of GIS

12. Growth of GIS substation

13. Future trends in GIS

14. Conclusion

Contents

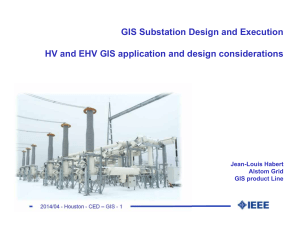

Introduction and governing standard

This presentation covers the technical requirements and design aspects of a gas-insulated

substation (GIS) as per governing standards of GIS substations.

Governing standard of GIS substation are:

1. IEEE Standard C37.123-1996 (Rev-2002)- IEEE Guide to Specifications for Gas-Insulated,

Electric Power Substation Equipment.

2. IEEE Standard 1300–1996, Guide for Cable Connections for Gas-Insulated Substations.

3. Components inside GIS switchgears (CB, CT, PT and Disconnecters) are governed by

their respective IEC standard. Prominent among them is IEC 62271-203, 200, 100

4. ASTM D2472–1992, Specification for Sulfur Hexafluoride.

5. NEMA CC 1–1993, Electric Power Connectors for Substations.

Conventional substations (AIS)

A:Primary power lines' side B:Secondary power lines' side

1.Primary power lines 2.Ground wire 3.Overhead lines 4.Transformer for measurement of electric voltage 5.Disconnect

switch 6.Circuit breaker 7.Current transformer 8.Lightning arrester 9.Main transformer 10.Control building 11.Security

fence 12.Secondary power lines

Conventional substations

(AIS)……continued

Power generating stations may be hydro, thermal or nuclear. Depending upon the availability of

resources these stations are constructed at different places. These places may not be nearer to load

centers where the actual consumption of power takes place. So it is necessary to transmit these

huge power blocks from generating station to their load centers.

Long and high voltage transmission networks are needed for this purpose. Power is generated at

medium voltage level. It is economical to transmit power at high voltage level. Distribution of

electrical power is done at lower voltage levels or as specified by consumer requirement.

For maintaining proper voltage levels at transmission and distribution level and for providing greater

stability a number of electrical transformation and switching setups have to be created in between

generating station and consumer ends. These transformation and switching setups are generally

known as electrical substations.

There are various ways to classify a substation. Based on purpose substation may be transmission

substation, distribution substation etc….Based on nature of dielectric medium a substation is of two

types AIS and GIS

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

32

33

33

34

34

35

35

36

36

37

37

38

38

39

39

1

/

39

100%