Sélectionner une langue

Fourni par Traduction

Accueil

FAQ

Avion

Aérospatial

Amphibiens

Ballons et dirigeables

Entre les guerres

Bombers

Premières machines volantes

Planeurs

Collection d'avions Grumman

Hélicoptères

Jets

Avion léger

Les hommes magnifiques et

leurs machines volantes

Pionniers du vol

Coureurs

Secret X-Planes Nazi

Formateurs

Avions étranges

Première Guerre mondiale

Alliés de la Première Guerre

mondiale

Pouvoirs centraux de la

Première Guerre mondiale

La Seconde Guerre mondiale

Alliés de la Seconde Guerre

mondiale

Axe de la Seconde Guerre

mondiale

Immeubles

Awesome New England Model Village

Anglais

Industrie

Les phares

Lone Ranger Town

Divers

Nouvelle-Angleterre

Maisons de livres d'histoire

Occidental

Véhicules

Bateaux

Voitures

Réservoirs de la Première Guerre mondiale

Chars de la seconde guerre mondiale

Divers

Rechercher des modèles

Mon compte

Dossier MyModels

Ordres

Information de

paiement

Mon adresse

Informations sur le

profil

Se connecter

Gloster-E28 - 5,50 $

S'inscrire

Aider un Model'n

Pal?

Autres pages

Forum

WSAM expliqué

Aide Model'n Pals

Angels

Pour les designers

Logos AC

Poster des

commentaires

Échelles de

modèle

Supports AC

Conseils de

montage

Accessoires

CONSEILS DE

MODÉLISATION

Clés et dossiers

magiques

WESTIE PUPS

Mobile Internet

Office

Indice

Informations sur

les échelles

Liens

Page Citations

Chips

Cartes de visite

Politique de

confidentialité

Affiches de dessin

animé

Modèles

réduits d'avions en

papier

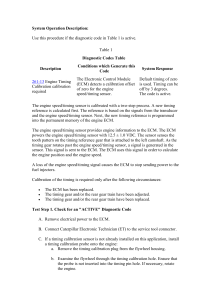

Le premier avion British Jet propulsé par le nouveau moteur centrifuge Whittle W1 à crocs. Il a

volé avec brio mais les Allemands n'y étaient déjà parvenus que depuis un an et demi. Le premier

jet allemand, le Heinkel He-178 est disponible. Le P-59 américain rejoindra la collection Jets dès

que possible.

Gloster E28 / 30 Whittle, premier avion à réaction britannique Pioneer

La naissance du jet

Le 8 avril 1941, un événement top secret qui allait révolutionner l'aviation mondiale eut lieu à

Brockworth dans le comté de Gloucestershire.

Après les premiers essais en taxi, le pilote PEG (Phillip Edward Gerald) Sayer a poussé le levier

d'accélérateur vers l'avant jusqu'à ce que l'indicateur du moteur indique 16000 tr / min et que le

Gloster E28 / 39, le premier avion à réaction de Grande-Bretagne, soit en vol.

Pour éviter la possibilité de dommages à la bombe à Brockworth, une cible probable de la

Luftwaffe, ce petit appareil avait été équipé du moteur révolutionnaire à turbine à gaz de Sir

Frank Whittle chez Regent Motors à Cheltenham, où se trouve maintenant le Regent Arcade. Au

cours de ces premiers essais, le E28 / 39 ou Gloster Whittle a réalisé trois sauts atteignant une

hauteur de seulement 1,8 m. Cela suffisait à distinguer l'aérodrome de Brockworth comme site du

premier vol à réaction allié et donc comme site du patrimoine de l'aviation internationale.

Selon Sir Ralph Robins, président de Rolls-Royce, «les travaux pionniers de Frank Whittle sur le

turboréacteur sont probablement l’invention mécanique la plus importante de ce siècle. par cela".

C'est cet événement qui constitue le pivot du musée JET AGE de la Gloucestershire Aviation

Collection.

Comment se fait-il que le premier avion à réaction britannique ait été conçu, construit et piloté

pour la première fois dans la tranquillité rurale du Gloucestershire?

Le fait surprenant est que le Gloucestershire peut se vanter d'une plus grande association avec

l'aviation et l'aérospatiale que n'importe quel autre comté de Grande-Bretagne.

Cette longue tradition, qui a vu de nombreux types d'avions célèbres construits par la Bristol

Airplane Company et Parnall dans le sud du comté jusqu'à la Gloster Aircraft Company dans le

nord, se poursuit aujourd'hui dans les moteurs Rolls-Royce de Filton à Messier-Dowty et Smiths

Industries aérospatiales près de Cheltenham.

La première histoire du Gloster Meteor est intimement liée aux efforts britanniques pour

développer des turboréacteurs. En 1929, un jeune officier de vol de la British Royal Air Force (RAF)

nommé Frank Whittle a eu des idées pour construire un moteur d'avion basé sur la turbine à gaz.

D'autres chercheurs ont joué avec le concept, mais Whittle a été le premier à avoir les compétences

en ingénierie et en aéronautique pour faire quelque chose d'utile.

Since all earlier attempts to develop an aircraft engine based on the gas turbine engine had failed,

and Whittle's notions were so new and unusual, he was generally dismissed by government and

industry authorities. However, Whittle was stubborn enough to apply for a patent on his ideas in

1930, and continued to promote his engine concepts, with a remarkably lenient RAF giving him

time and opportunity to pursue the matter.

In 1936, Whittle set up a small

firm named Power Jets LTD to

pursue his ideas, and was soon

applying for new patents. One

was for a "bench-test" gas-turbine

engine designated the "Whittle

Unit (WU)". Whittle began tests of

the WU in 1937. The tests were

successful, if sometimes

extremely frightening, with the

engine having a nasty tendency

to go into violent runaway

operation. Fortunately, Whittle was not killed or maimed, and managed to get the WU working

well enough that by 1938 the British Air Ministry began to provide him with moderate funds to

continue his work.

In June 1939, with the WU working in a reliable and impressive fashion, the Air Ministry ordered a

flight-worthy engine, the "W.1", from Power Jets. In September 1939, the Air Ministry also ordered

that Gloster design an aircraft, the "E.28/39", to test-fly the engine. In the meantime, Whittle was

hearing rumors that the Germans were also working on "turbojet" engines, as they came to be

known.

Things were still not smooth sailing for Whittle. The Air Ministry was interested in his engine, but

it wasn't the highest priority, and by September Britain was in a war that the country was poorly

prepared to fight. In fact, by the summer and fall of 1940, Britain was struggling against German

Luftwaffe air fleets that pounded the island, with an invasion seeming imminent.

Despite the disruption caused by the

Battle of Britain, work on turbojet

engines and aircraft continued at a low

level. In fact, in 1940 the Air Ministry

issued a request, designated "F.9/40", for

an operational turbojet-powered fighter.

Given that Whittle's W.1 and its possible

derivatives appeared significantly

underpowered, Gloster's chief engineer

George Carter proposed a twin-engine

aircraft with the company designation

"G.41" for the specification.

The proposal was approved in

November 1940, with a batch of twelve

prototypes ordered on 7 February 1941.

The G.41 was named "Thunderbolt" in

September 1941, but in early 1942 it

became apparent that this would cause

confusion with the new American

Republic P-47 Thunderbolt, and the name was changed to "Meteor". Some sources also claim that it

was called "Rampage" during trials, though this appears to have been a cover name used for

security purposes.

The first of two experimental E.28/39 test aircraft,

which had the company designation of "G.40" and

were known informally as the "Gloster Whittle",

began taxi trials with an non-airworthy W.1X engine

on 8 April 1941, with Whittle himself performing

some of the tests, and Flight Lieutenant P.E.G.

"Gerry" Sayer, Gloster's chief test pilot, performing a

few "hops" off the runway that same day. After the

aircraft was refitted with a proper W.1 engine, Sayer

performed the first real flight in the aircraft on 15

May 1940, with everything going smoothly, and

Sayer having nothing but good to say about the

experience.

The second G.40 did not fly until March 1943. It would be lost due to a flight malfunction four

months later, with the pilot baling out successfully. The first would eventually end up as a museum

piece.

The G.40 was a simple all-metal "flying stovepipe" design, with a low-mounted straight wing and

retractable tricycle landing gear. It was powered by a single Whittle W.1 engine, providing 850 lbf

thrust. It had a wingspan of 29 feet, a length of 25 feet 4 inches, a maximum loaded weight of 3,700

pounds, and a modest top speed of 338 MPH.

Well, it was a beginning. Power Jets continued to refine the design to create the "W.2B" series

engines, which incorporated successive refinements until they provided almost 2,500 lbf thrust.

The different engine subvariants were all the same diameter and could be flight-tested in the G.40

aircraft, which ultimately obtained a top speed of at least 466 MPH.

Lutterworth and the Birth of the Jet Engine

By Roger Jones, The Whittle Society.

Frank Whittle first formed the idea of using

gas turbines to drive aircraft at far higher

speeds and altitudes than so far reached

whilst still a RAF cadet at Cranwell. It was not

until nine years later, having served as a test

pilot and awarded a 1st class degree at

Cambridge, that he was able to complete a

proof of concept engine and ran it successfully

at the British Thompson- Houston works at

Rugby on 12th April 1937.

Unfortunately, in these early runs, the engine

showed a distinct tendency to run out of

control so that BT suggested that it might be safer if the testing was continued up the road at a

disused foundry they

owned at Lutterworth.

Power Jets, the company

that he had formed to

develop his ideas, moved

into the Ladywood Works

on the east side of the

Leicester Road at the

beginning of 1938 with

one employee. Here, two

further versions of the

original engine were

tested and the team

gradually grew as talented graduates and experienced technicians were recruited. In July 1939

with war looming, the government placed an order for a flight engine. Image of the test bed at

Ladywood in Lutterworth Museum.

Locals still remember the influx of "boffins" who were billeted on local households and the

continuous sound of engine testing claiming that when it sometimes when it stopped in the night

the silence woke them up. Meanwhile an engine mounted on a truck was used to help clear snow

from the High St. and a hawthorn hedge in line with the efflux of engines under test burst into

flower in February.

After building and testing a interim engine the flight engine,

W1, was assembled and run in April 1941. On 15th May it

flew at Cranwell in the specially designed Gloster E28/39

aircraft. Some nine months earlier, unknown to the allies, the

Germans had flown an experimental gas turbine engine

designed by Otto Von Ohain.

With the government at last behind the project, W1 was

further developed and a new engine designed and tested to

power a twin engined fighter, the Gloster Meteor. Meanwhile

a production facility was being built some seven miles up the road in Whetstone. Power Jets finally

moved out of Ladywood Works in 1946

First British Jet Pilot:

Sayer's first actual flight

in the E28/39 consisted

of some short hops of

between 100 and 200

yards at Hucclecote on

the 7th April 1941 while

the aircraft was still

fitted with its first W1X

(Taxi only) engine. The

aircraft was then moved

to Cranwell where it

received its flight ready

engine. The first offical

flight took place at 7pm

on the 15th May 1941

and lasted 17 minutes

due to its minimal fuel

load. Over the next

thirteen days he

completed a further ten

hours of test flights at

altitudes up to 25,000

feet with the longest of

just under an hour with

its maximum load of 81

gallons.

Sayer was killed flying a

Typhoon in 1942 on a

visit to RAF Acklington

in Northumberland. The

cause of the accident

was never determined

but it is thought that he

collided in the clouds

with the other aircraft

he was flying with.

Following the loss the

task of continuing the

flight test program fell to

his assistant Michael

Daunt who would go on

to test-fly the early

Meteors.

6

6

7

7

8

8

9

9

10

10

11

11

1

/

11

100%