ABB Drives

MAINTENANCE INSTRUCTION

Technical Description

3AFE 6479 3675

00262693_E.DOC

Dept.

Project

STRAW

BERRY

Status Date

16.Nov 2011

Author

LAHTINEN JUHANI

Status

APPROVED/KARVINEN RAUNO

Revision

E

Page

1 / 66

Safety Issues and ESD .........................................................................................................................2

Voltage Measurement......................................................................................................................3

High Center of Gravity ....................................................................................................................3

ESD..................................................................................................................................................3

Cabinet and Module Serial Numbers...................................................................................................4

Serial Number Hierarchy.................................................................................................................4

ACS800-X7 Cabinet....................................................................................................................4

ACS800 MD Line-up ..................................................................................................................5

Practical Examples ..........................................................................................................................5

Filling Out the Warranty Report..........................................................................................................9

General Description of the ACS800-104 Module .............................................................................12

Option Codes .................................................................................................................................12

Parts List ........................................................................................................................................13

Mechanical Parts for module with option code +V991.............................................................13

Mechanical Parts for old R8i module (without +V991) ............................................................17

Electrical Parts...........................................................................................................................20

About Maintenance Procedures.........................................................................................................23

Testing the Module after Maintenance..........................................................................................23

ACS800-104 On-Site Tester......................................................................................................23

Maintenance of the Fan .....................................................................................................................23

Maintenance Tips: Left Hand Side of the Module ............................................................................24

Replacing the Controlled Fan Option (+C126) Circuit Boards.....................................................24

Replacing an AFPS-01C board with and AFPS-11C board ......................................................25

Replacing the Control Unit Circuit Boards ...................................................................................29

Replacing the AGBB board (Module with 2 x IGBT)...................................................................30

Replacing the IGBT/AGDR modules............................................................................................32

Replacing the Module Heating Set (+C123) .....................................................................................34

Maintenance Tips: Right Hand Side of the Module ..........................................................................35

Replacing the AOFC-0XC Filter Capacitor Board (+E205) .........................................................35

Replacing the ATMB-01C Temperature Measurement Board......................................................36

Replacing the Current Transducers ...............................................................................................37

Maintenance Tips: Replacing the AOFI-XX du/dt output filter (+E205) .........................................42

Maintenance Tips: Replacing the DC Capacitor Bank......................................................................47

Electrolyte Capacitor. ....................................................................................................................47

Film Capacitor (+E212).................................................................................................................55

Appendix I: Capacitor layouts for 300 - 500 V ElCo........................................................................59

Appendix II: Capacitor layout for 690 V ElCo..................................................................................62

Appendix III: Module phase order.....................................................................................................65

ABB Drives

MAINTENANCE INSTRUCTION

Technical Description

3AFE 6479 3675

00262693_E.DOC

Dept.

Project

STRAW

BERRY

Status Date

16.Nov 2011

Author

LAHTINEN JUHANI

Status

APPROVED/KARVINEN RAUNO

Revision

E

Page

2 / 66

Safety Issues and ESD

WARNING! All electrical installation and maintenance work on the ACS 800

should be carried out by qualified electricians.

Do not attempt any work on a powered ACS 800. After switching off the

mains, always allow the intermediate circuit capacitors 5 minutes to

discharge before working on the frequency converter, the motor or the motor

cable. The voltage between each input terminal (U1, V1 and W1) and earth

must be measured with a multimeter (impedance at least 1MΩ) to ensure that

the frequency converter is discharged before beginning work.

All insulation tests must be carried out with the ACS 800 disconnected from

the cabling.

The ACS 800 motor cable terminals are at a dangerously high voltage when

input power is applied, regardless of motor operation. No work on the motor

cable should be attempted with mains power applied.

There can be dangerous voltage inside the ACS 800 from external control

circuits when the ACS 800 input power is shut off. No work on the control

cables should be attempted when power is applied to the frequency

converter or to the external control circuits. Exercise appropriate care when

working with the unit.

ESD (Electro Static Discharge)! The printed circuit boards contain

integrated circuits that are extremely sensitive to electrostatic discharge.

Exercise appropriate care when working on the unit to avoid permanent

damage to the circuits. Do not touch the boards unnecessarily.

WARNING! Only qualified electricians are allowed to carry out work

described in this instruction. Before working with the ACS 800 or handling

the IGBT modules, read carefully the Safety Instruction on the ACS800

Hardware Manual. Ignoring the safety instructions can cause injury or

death.

ABB Drives

MAINTENANCE INSTRUCTION

Technical Description

3AFE 6479 3675

00262693_E.DOC

Dept.

Project

STRAW

BERRY

Status Date

16.Nov 2011

Author

LAHTINEN JUHANI

Status

APPROVED/KARVINEN RAUNO

Revision

E

Page

3 / 66

Voltage Measurement

When repairing a module one must always to remember that there might be live voltages on some

components such as capacitors. Therefore, before disconnecting the module from the cabinet, it

is important to measure the dc voltage with a multimeter.

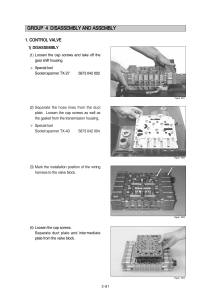

High Center of Gravity

The ACS800-104 module has an exceptionally high center of gravity. When performing

maintenance operations for the module, it is important to make sure that the module is pulled out

from the cabinet by using a service ramp (Figure 1) and that both support legs in the rear side of

the module are opened during the maintenance (Figure 2).

Figure 1: Pulling the module out safely. Figure 2: Supporting the module during maintenance.

ESD

Always use ESD protection clothes, gloves, shoes and mat if possible. Avoid unnecessary

touching of the circuit boards.

ABB Drives

MAINTENANCE INSTRUCTION

Technical Description

3AFE 6479 3675

00262693_E.DOC

Dept.

Project

STRAW

BERRY

Status Date

16.Nov 2011

Author

LAHTINEN JUHANI

Status

APPROVED/KARVINEN RAUNO

Revision

E

Page

4 / 66

Cabinet and Module Serial Numbers

Each cabinet, module and circuit board is equipped with a serial number. In this context, the

essential serial number information is collected from cabinet and module, which in this case refers

to an ACS800-104-XXXX-Y –inverter module.

The serial number is needed in order to maintain the field quality statistics as well as the event

history of a single cabinet and module. This has a significant strategic importance in ABB Drives’

products and should be considered as an imperative each case a warranty repair is performed.

The following three chapters include important information about serial number hierarchies of

different cabinets and modules as well as practical examples on how to find the right serial

number for each case and how to fill the warranty report

Serial Number Hierarchy

ACS800-X7 Cabinet

Single drive serial numbers can be divided into two levels: cabinet level and module level (Figure

3). If for example the module has faulted, both cabinet and module level serial number is needed.

On the other hand, if f. ex. one of the control boards has a defect in it, only the cabinet level serial

number is needed for the control board cannot be traced to a module. The module serial number

is always in the same spot.

Figure 3:Serial number hierarchy of an ACS800 single drive cabinet. The type codes and serial number of the

units enclosed by a red rectangle are important.

ABB Drives

MAINTENANCE INSTRUCTION

Technical Description

3AFE 6479 3675

00262693_E.DOC

Dept.

Project

STRAW

BERRY

Status Date

16.Nov 2011

Author

LAHTINEN JUHANI

Status

APPROVED/KARVINEN RAUNO

Revision

E

Page

5 / 66

ACS800 MD Line-up

The multidrive serial number hierarchy is more complicated than the one for single drives (Figure

4). The first level is the device level witch is the MDs serial number. However this has little

significance for the statistics. That is why the first and second levels (device level and TL level)

are not needed for warranty reports. The serial number information needed in warranty report is

the unit level serial number and the module level serial number. If for example the module is

defected, both unit level serial number and module level serial number is needed. In Figure 4 this

means f. ex. the serial numbers from drive unit (ACS800-107-0400-7) and the module it contains

(ACS800-104-0400-7).

Sometimes the equipments are not in the same cabinet as the unit type code. Situation like this is

encountered with control boards. When again referring to Fig. 2 this could mean that the control

board RDCU-12C for unit ACS800-107-0400-7 is mounted to another locker. It must be bared in

mind that no matter where the control board is mounted, the important fact is that it controls the

mentioned unit. In this case only the unit level serial number is needed. The module serial number

is always in the same spot.

Figure 4: Serial number hierarchy of an ACS800 multi drive cabinet. The type codes and serial number of the

units enclosed by a red rectangle are important.

Practical Examples

There are some differences between the placing of the serial number stickers in different

cabinets, such as ACS800-X7 and ACS800MD. In general the serial number and type of the

ACS800-X7 cabinet can be found on the lower right side of the first cabinet door, that is, right

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

32

33

33

34

34

35

35

36

36

37

37

38

38

39

39

40

40

41

41

42

42

43

43

44

44

45

45

46

46

47

47

48

48

49

49

50

50

51

51

52

52

53

53

54

54

55

55

56

56

57

57

58

58

59

59

60

60

61

61

62

62

63

63

64

64

65

65

66

66

1

/

66

100%