SPRING EDITION

2

Contents

3 — How to launch a successful predictive maintenance

program

11 — Six critical components of integrated cybersecurity for

industrial control systems (ICS)

18 — PLCs power industrial data integration

27 — How automation can help with high demand

30 — The Benets of Edge Computing

35 — Cybersecurity-centered systems and fundamentals

43 — Creating value from advanced analytics to improve

operations

How to launch a

successful predictive

maintenance program

Six critical components of

integrated cybersecurity for

industrial control systems

(ICS)

PLCs power industrial data

integration

How automation can help

with high demand

The Benets of Edge

Computing

Cybersecurity-centered

systems and fundamentals

Creating value from

advanced analytics to

improve operations

3

How to launch a successful

predictive maintenance program

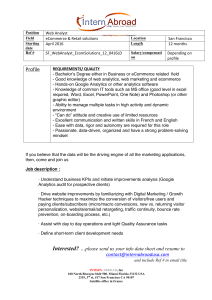

An approach that keeps people at the center of the digitalization project has

a better chance of success

A

predictive maintenance program (PdM) anticipates the future state of physical

assets and makes timely and better-informed maintenance decisions. PdM — as

well as the idea of Industry 4.0 — depends on achieving a convergence of information

technologies (IT) and operational technologies (OT). We believe bringing together

people, process and technology is the key to a successful predictive maintenance

program. If you look at Industry 4.0 tools in general and at predictive maintenance

specically, one of the key metrics it can impact is the overall equipment effectiveness

(OEE) of an operation, which includes uptime, performance speed, and quality, as well

as labor productivity.

Digitalizing and implementing such tools has immediate impact on providing real-time

data analytics and prediction to the maintenance and quality function, as well as sig-

nicantly improving labor productivity. It shifts the mindset from a reactive, potentially

manually driven operation to a more predictive, prescriptive and proactive operation

(see Figure 1).

But it’s not just about improving uptime. It’s also about linking to other systems with-

in the operation, especially maintenance systems, spare parts systems, maintenance

scheduling and labor allocation, so management can achieve predictive insights. Spare

parts on hand can be reduced, which also reduces overhead for the business. More

proactive scheduling and even predictive spare parts replenishment is possible. The

How to launch a successful predictive maintenance program

4

How to launch a

successful predictive

maintenance program

Six critical components of

integrated cybersecurity for

industrial control systems

(ICS)

PLCs power industrial data

integration

How automation can help

with high demand

The Benets of Edge

Computing

Cybersecurity-centered

systems and fundamentals

Creating value from

advanced analytics to

improve operations

vision is driving toward near-zero downtime and near-zero waste

within the manufacturing space and directly impacting the busi-

ness in a positive and protable way.

So, where to start? How does one set up a successful predictive maintenance program

that can lead to a direct impact on the business bottom line?

Dene “digital,” establish a core purpose

A PdM or any other digital program can’t be launched in an organization without know-

ing exactly what digital means. A critical rst step is attaining a common denition of

“digital” for the organization.

Figure 1: The predictive

maintenance opportunity.

Courtesy: IoTco

How to launch a successful predictive maintenance program

5

How to launch a

successful predictive

maintenance program

Six critical components of

integrated cybersecurity for

industrial control systems

(ICS)

PLCs power industrial data

integration

How automation can help

with high demand

The Benets of Edge

Computing

Cybersecurity-centered

systems and fundamentals

Creating value from

advanced analytics to

improve operations

One favorite for the authors is: “Digitalization is a nearly instant, free and awless abili-

ty to connect people, devices and physical objects anywhere.” Admittedly, it’s a broad,

simple denition, but it’s all about connectivity and sharing information. It’s at the core

of data management and helps create program identity.

With a common denition in place, the next task is to dene the core purpose of the

initiative: establishing the “why.”

We’ve all been around initiatives where the “why” wasn’t clearly established, and they

all fail. It’s important to make it clear what the purpose is — and what it isn’t. The goal

is not implementing new technology because there is new technology to implement.

Rather, it’s solving real business issues. It’s creating new core competencies and inte-

grating business functions that will improve the bottom line.

We’re applying technology and newer processes into mainstream manufacturing where

they hadn’t been before. At the end of the day, this is a different way of thinking. If the

bottom-line goals of the program are not constantly kept in view of all its participants,

the long-term success of the program will remain elusive.

Assessing before executing

Consider these rst steps for digital transformation of an enterprise. With that initial

framework in mind, Let’s look at using PdM as a specic transformation worth pursuing.

After establishing the core purpose for stakeholders, identify targeted outcomes and

digital focus areas that suit that purpose. This calls for assessment of the status quo.

It’s done with a team that includes the plant manager (or an appointed deputy) and

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

32

33

33

34

34

35

35

36

36

37

37

38

38

39

39

40

40

41

41

42

42

43

43

44

44

45

45

46

46

47

47

48

48

49

49

50

50

51

51

52

52

53

53

1

/

53

100%