Material Testing and 3D Drawings Enhance

Engineering Precision.

A seemingly flawless metal structure once collapsed under minimal stress during

a factory trial. The issue wasn’t in the design; it was in the material. This highlights

why lab test and material analysis are crucial in engineering projects. Through

accurate testing, manufacturers verify material strength, durability, and

compliance with standards, avoiding costly failures and ensuring that end products

meet performance expectations.

Analyzing Composition for Reliability

The true nature of any engineering component lies within its internal composition.

With lab test and material analysis, experts uncover the presence of impurities,

inconsistencies, or structural flaws in metals, polymers, and composites. These

insights guide engineers in selecting suitable materials that can handle specific

pressures, temperatures, or environmental exposures, ultimately contributing to

safer and longer-lasting constructions and machinery.

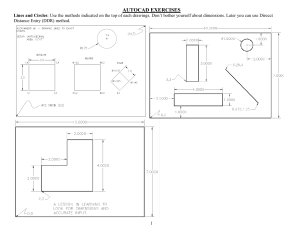

Visualization Through Smart CAD Modeling

Modern manufacturing begins long before machines start cutting or shaping

materials. The introduction of 3D CAD Drawing Services has revolutionized

design by providing highly detailed visual representations of parts or systems.

These digital drawings allow stakeholders to visualize, assess, and modify products

before they enter production, minimizing errors and enhancing collaboration

between design and engineering teams across different locations.

Reducing Errors in Manufacturing Steps

A common reason for production delays is a misinterpretation of technical

drawings. By utilizing 3D CAD Drawing Services, designers can reduce these

mistakes by offering precise, scaled, and realistic digital models. These models

are easy to understand and replicate, ensuring that production teams follow exact

specifications, leading to fewer reworks and more consistent output quality

throughout the entire manufacturing process.

Improved Quality Through Material Insights

Before launching any project, understanding how a material will behave under

stress is essential. This is where lab test and material analysis become vital.

Whether checking tensile strength, corrosion resistance, or thermal properties,

these tests ensure that each material is suitable for its intended purpose. Such

analysis enables quality control, supports innovation, and fosters trust in both

industrial and commercial applications.

Smarter Designs with CAD Precision

From aerospace to consumer electronics, innovation thrives on precision. With 3D

CAD Drawing Services, engineers and designers are empowered to create

optimized, functional, and visually detailed designs tailored to specific

requirements. These drawings can be used for simulations, stress testing, and

virtual prototyping, enhancing accuracy and functionality even before a single part

is physically produced or tested.

Conclusion

Advanced design and engineering success depend on solid data and precision

modeling. The combination of lab test and material analysis, and 3D CAD Drawing

Services ensures that every material is validated and every design is accurately

rendered before production begins. To access professional services that bring

clarity and accuracy to your engineering process, visit feamax.com. With technical

expertise and reliable insights, each project moves forward with greater

confidence.

1

/

3

100%