Comprehensive Guide to Hardness Testers and Microscopes in Malaysia

Telechargé par

Tosif Khan

Comprehensive Guide to Hardness Testers and Microscopes in

Malaysia

Hardness testing and microscopy are essential for industries like manufacturing, research, and quality

control. Whether you're dealing with metals or non-metals, testing the hardness of materials and

studying them at microscopic levels are crucial. In Malaysia, Takumi Precision offers a range of high-

quality hardness testers and microscopes. This guide will explore different types of hardness testers and

microscopes available, focusing on their applications and benefits.

1. Hardness Testing: An Overview

Hardness testing is a technique used to determine the material’s resistance to deformation. It's

particularly important in the metalworking industry for quality assurance and research purposes.

Various methods can be used to measure hardness, with the most common being Rockwell, Vickers, and

Brinell tests.

Why is Hardness Testing Important?

Hardness testing provides insight into the durability, wear resistance, and overall quality of materials. It

helps determine whether a material is suitable for a specific application, such as machinery parts, tools,

or structural elements.

2. Types of Hardness Testers Available in Malaysia

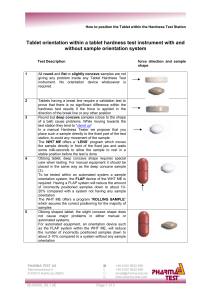

a. Rockwell Hardness Tester Malaysia

The Rockwell hardness tester is one of the most widely used methods for hardness testing, especially for

metals like steel and alloys. This method measures the depth of indentation caused by a penetrator

under a heavy load.

Key Features of Rockwell Hardness Testers:

Fast and Efficient: Results are produced quickly, making it ideal for production environments.

User-friendly: The simple operation allows technicians to conduct tests with minimal training.

Versatile: Can be used for both hard and soft materials, ranging from metals to plastics.

Industries in Malaysia often rely on Rockwell hardness testers for their speed and accuracy, particularly

when testing bulk materials for manufacturing purposes.

b. Vickers Hardness Test Malaysia

The Vickers hardness tester uses a diamond indenter to press into the material, and the size of the

indentation is measured under a microscope. Unlike the Rockwell test, the Vickers method can be used

for both very hard and very soft materials, making it a versatile option.

Benefits of Vickers Hardness Testers:

Precision: This method is more accurate for testing materials like ceramics, thin sheets, and coatings.

Wide Range: The Vickers method works on a variety of materials, from steel to glass.

Detailed Results: Provides in-depth data about the material's hardness.

This method is commonly used in Malaysia for more precise applications, such as aerospace,

automotive, and advanced manufacturing sectors.

c. Digital Hardness Testers

Digital hardness testers are gaining popularity for their ease of use and digital readouts, which reduce

the chance of human error. These testers often come equipped with software that allows data logging

and advanced analysis.

Advantages:

Efficiency: Digital readouts provide faster and more accurate results.

Data Tracking: Ideal for companies that need to maintain strict quality control records.

Advanced Capabilities: Some models offer multiple testing methods in one device, such as Rockwell and

Vickers.

Digital hardness testers are increasingly preferred in industries across Malaysia for their efficiency and

versatility.

3. Microscopes: Precision Tools for Detailed Analysis

In addition to hardness testing, microscopy plays a crucial role in material analysis. Two types of

microscopes dominate the industrial and research sectors: digital microscopes and stereo microscopes.

a. Digital Microscope Malaysia

Digital microscopes are equipped with cameras and software to capture high-resolution images of the

sample. This type of microscope is perfect for educational, industrial, and research purposes.

Features of Digital Microscopes:

High Magnification: Offers magnification levels far beyond traditional microscopes, enabling the study of

fine details.

Data Storage: Allows users to store and analyze images on a computer.

Versatility: Ideal for a variety of applications, from electronics inspection to biological research.

In Malaysia, industries such as electronics and materials science frequently use digital microscopes for

their precision and ease of use.

b. Stereo Microscope Malaysia

Stereo microscopes are essential for applications that require depth perception and a three-dimensional

view of the sample. They are commonly used for inspecting larger samples that don’t require extremely

high magnification.

Key Benefits of Stereo Microscopes:

3D Imaging: Provides a three-dimensional view, making it easier to study the surface texture of

materials.

Lower Magnification: Perfect for tasks like assembly inspection, dissection, and surface analysis.

User-friendly: Easy to operate, making it suitable for both industrial and educational purposes.

Stereo microscopes are widely used in Malaysia for tasks like circuit board inspection, gemstone

analysis, and biological dissection.

4. Selecting the Right Equipment for Your Needs

When choosing hardness testers or microscopes, it’s essential to consider your specific industry

requirements. Here are some factors to consider:

Hardness Testers:

Material Type: Whether you're working with metals, ceramics, or softer materials will determine the

best hardness testing method.

Testing Volume: For high-volume testing, Rockwell testers might be the best choice due to their speed.

Precision Needs: If you're dealing with delicate materials or coatings, the Vickers hardness test might be

more suitable.

Microscopes:

Magnification Needs: Digital microscopes offer higher magnification, while stereo microscopes are

better for larger samples that don’t require extreme zoom.

3D vs 2D Imaging: Stereo microscopes are ideal for applications that require depth perception, while

digital microscopes excel in capturing and analyzing two-dimensional images.

Conclusion

For industries in Malaysia, having the right tools for material testing and analysis is crucial. Hardness

testers, whether Rockwell, Vickers, or digital, provide invaluable data for ensuring material quality and

durability. Meanwhile, digital and stereo microscopes offer detailed visual analysis, essential for

research and inspection.

At Takumi Precision, we offer a wide range of these tools to meet your needs. Whether you need a

Rockwell hardness tester, a Vickers hardness tester, or a digital microscope, we have you covered with

high-quality options. Visit our website at Takumi Precision to explore our full range of products and find

the right solution for your testing and analysis needs.

Experience the precision and quality that Takumi Precision offers, and elevate your industry standards

today.

For more information, please visit: https://takumiprecision.com.my/product-

category/hardness-tester/

1

/

4

100%