CNC ROTARY TABLE for

FANUC ROBODRILL

CNC ROTARY TABLE for

FANUC ROBODRILL

5AX-201FA

5AX-DD200BF2

Assembling

(Large Rotary Table)

Heat Treatment Welfare Facility

Parts warehouse

Material House

Central Control

Land :55,000m2

Building :27,800m2

Land :55,000m2

Building :27,800m2

Factory No.1

Turning

Machining

Grinding

Assembling

Inspection

Factory No.2

Grinding

Assembling

Inspection

Warehouse

Office

Management

Sales

Design / Development

Financial

■Please give your order to the following agent.

●Specifications are subject to change without notice.

http://www.nikken-kosakusho.co.jp/en

e-mail : [email protected]

5-1, 1-chome, Minamishinden, Daito-shi, Osaka-fu, Japan. Telephone:072-869-5820 Telefax:072-869-6220

NIKKEN KOSAKUSHO WORKS, LTD. OSAKA, JAPAN.

GERMANY

NIKKEN DEUTSCHLAND GmbH

Eisenstraße 9c, 65428 Rüsselsheim

Tel.+49-(0)-6142-550600 Fax.+49-(0)-6142-5506060

ITALY VEGA INTERNATIONAL TOOLS S.P.A

Via Asti N・9 10026-Santena(TORINO)

Tel.+39-011-9497911 Fax.+39-011-9456380

U.S.A

CA, CT, IL, NC, TX, WA

LYNDEX-NIKKEN Inc

1468 Armour Boulevard,

Mundelein, ILLINOIS 60060

Tel.+1-847-367-4800 Fax.+1-847-367-4815

FRANCE PROCOMO-NIKKEN S.A.S

6, avenue du 1er Mai-Z.A.E.Les Glaises 91127

Palaiseau Cedex

Tel.+33-(0)-1-69.19.17.35 Fax.+33-(0)-1-69.30.64.68

MEXICO

(From 2014.09)

HERRAMIENTAS LYNDEX-NIKKEN S.A.de C.V.

Av. Hercules #401-13, Fracc. Poligono 3

Santa Rosa Jauregui, Queretaro 76220

Tel.+52-55-8421-8421

UK NIKKEN KOSAKUSHO EUROPE LTD.

Precision House, Barbot Hall Industrial Estate,

Rotherham, South Yorkshire, S61 4RL

Tel.+44-(0)-1709-366306 Fax.+44-(0)-1709-376683

KOREA KOREA NIKKEN LTD.

90B-11L, Namdong Industrial Complex, 170,

Namdong-Daero, Namdong-Gu, Incheon, Korea 405-819

Tel.+82-(0)-32-763-4461 Fax.+82-(0)-32-763-4464

D.NH.1

SPAIN &

PORTUGAL

CUTTING TOOL S.L

Portuetxe 16, Barrio Igarra

E-20018 Donostia-san Sebastian

Tel.+34-(0)-902-820090 Fax.+34-(0)-902-820099

UTILLAJES OLASA,S.L.

Tel.+34-(0)-943-107177

TURKEY

NIKKEN KESICI TAKIMLAR SAN. VE ULUSLARARASI TIC. A. S

E5 Uzeri Kucukyali Yanyol Irmak Sok.

Kucukyali Sanayi Sitesi A Blok No:5 Maltepe 34852 Istanbul

Tel.+90-(0)-216-518-1010 Fax.+90-(0)-216-366-1414

SCANDINAVIA

SWEDEN

NIKKEN SCANDINAVIA AB

Malmövägen 14 331 42 Värnamo Sweden

Tel.+46-(0)-303-440-600 Fax.+46-(0)-303-58177

P.R.CHINA SHANGHAI ZHONG YAN TRADING CO., LTD.

Building 1/f, #54, No.1089 Qinzhou Rd.(N),

Shanghai, China

Tel.+86-(0)-216210-2506 Fax.+86-(0)-216210-2083

SINGAPORE NIKKEN KOSAKUSHO ASIA PTE, LTD.

186,Woodlands Industrial Park E5 #04-01

M Singapore 757515

Tel.+65-6362-7980 Fax.+65-6362-7980

THAILAND SIAM NIKKEN Co., LTD.

127 Moo5 Gauwungsai-Bangturie Road Tambon Tanokkard

Ampher Muangnakhonpathom Nakhonpathom 73000 Thailand

Tel.+66(02)178-0503 Fax.+66(02)178-0504

PT.NIKKEN KOSAKUSHO INDONESIA

JALAN BIZPARK 3 JABABEKA INNOVATION CENTER A NO.16,

KEL.MEKARMUKTI, KEC. CIKARANG UTARA, KAB.

BEKASI PROP. JAWA BARAT

TEL:+62-(0)21-5702071 MAIL:[email protected]

INDONESIA

NCT200LFA

CNC205LFA

5AX-100FA

NIKKEN

KOSAKUSHO

WORKS,

LTD.

CAT.NO.

8211

Headquarter

NCT200

EL

F

A

-

M

Code No. of vertical/horizontal type CNC rotary table

CNC Rotary Table

NCT : Standerd

NCTZ : High Speed

Code No. of vertical/horizontal type CNC rotary table CNC : Standerd CNCZ : High Speed

Diameter of the rotary

table face plate (mm)

Diameter of the rotary table face plate (mm)

Motor mounting location

Non: Right mount, L: Left mount

Face Plate

W/O Face Plate : E

With Face Plate : No Letter

Motor maker

Type of motor Non: DC servo, A: AC servo

With/without Motor Non: without motor

M: with motor

CNC

*Code No.

Makers for Additional Axis CTRL

FANUC F

180

Motor maker (

*

Code No.)

Type of motor Non : DC servo, A: AC servo

With / without Motor Non : without motor M : with motor

FL A - M

NCT200

5AX- 201 F A - M

5AX-201

Code No. of Rotray & Tilting Table

Diameter of the table face plate (mm)

Type of motor Non: DC servo, A: AC servo

With/without Motor

Non: without motor, M: with motor

Motor maker

OP

ACC

TEC

NET

■SUPPORT TABLE

■TAILSTOCK

■SCROLL CHUCK

■POWER CHUCK

■Rotary Joint

■Type of Rotary Joint

■High Precise Indexing

■High Precise Indexing with Thru-hole

■Relation between Unbalancing Load

and Servo Motor

■

Flow Chart of the Additional Axis Control

■Notes on the Use of DD TABLES

■Accuracy Standard

■Technical Information

■WORLD WIDE SALES BRANCH

■Headguater

ACCESSORIES

・・・

P.15

M-

SIGNAL

■α21 and EZ controller feature

■α21 and EZ controller connection

■Input / Output Time Chart

■Connection for Automatic Operation

TECHNICAL

INFORMATION

・・・

P.17

WORLDWIDE

NETWORK

・・・・・・・P.21

CNC105LFA

CNC205LFA

5AX-100FA

5AX-DD100AF

CNC180LFA

CNC202LFA

CNC205LFA

CNC260LFA

NCT200LFA

NCT200ELFA

5AX-130FA

5AX-201FA

5AX-DD200AF2

5AX-DD200BF2

α-D14SiB5

/

α-D14SiB5ADV

α-D21SiB5

/

α-D21SiB5ADV

P. 3

α-D14MiB5 /

α-D14MiB5ADV

α-D21MiB5 /

α-D21MiB5ADV

α-D14LiB5

/

α-D14LiB5ADV

α-D21LiB5

/

α-D21LiB5ADV

P. 6

It is not exaggeration that the most important parts of the CNC rotary table is worm system. Please choose

NIKKEN CNC rotary table with special worm system for our anti-wearing, high rigidity and high speed rotation.

CNCZ202

(66.6min-1)

Bronze/

Aluminium Bronze

Worm Wheel

(

33.3min-

1

)

NIKKEN CNC Rotary Table

Useful Life3mon. 6mon. 12mon. 2yrs. 3yrs.

Adjustment of Backlash

Backlash(Amount of wearing)

Hardness of Worm Wheel

Depth 0.1mm

HV980

+αInside

HRC36

Worm Wheel of Others

(Bronze/Aluminium Bronze)

micron

ANTI-WEARING, HIGH RIGIDITY and HIGH SPEED ROTATION

■Worm Wheel

Specially hardened and

furthermore ion-nitrided on the

tooth. Thus, the problem of the

sliding friction is solved. The

hardness of the tooth surface and

inside is shown at right hand side.

Worldwide Field-proven

NIKKEN CNC Rotary Table

Worm Wheel

HV980+α

Steel Way

HRC58~60

Special Worm Screw

When mounting a CNC ROTARY TABLE on ROBODRILL, the machine needs an additional axis option.

(Servo amplifier, connector unit, etc.)

You need to be careful when using CNCROTARY tables in foreign countries. In the case of machines for Europe and

China, the connector unit is different from that for general use Please contact the machine specifications when ordering.

If you want to mount the tilt CNC rotary table on a machine that supports only one additional axis, or if you can not

prepare the additional axis, you can select with a NIKKEN controller.

NIKKEN

CONTROLLER

・・・ P.13

OPTIONAL

EQIPMENTS

・・・・・・

P.14

Motor mounting location Non: Right mount, L : Left mount, B: Back mount, T : Top mount

■ Additional Axis ■ NIKKEN Controller (M-signal)

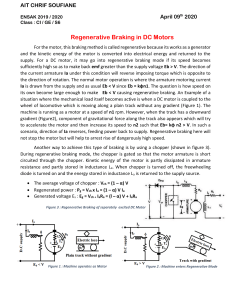

How CNC Rotary Table is Controlled

You can choose additional axis when the machine has 4th

or 5th axis.

CNC rotary table can be controlled by machine in this case.

1. 4th or 5th amplifier is required for the machine. It should be

used exactly the same one used for X, Y and Z axis. Install

same servomotor(s) used for X, Y and Z axis.

2. The type of the servomotor or amplifier is defined by the types

of rotary table.

3. Decide by whom servomotor will be supplied.

4. External dimensions and specifications depend on the type of

servomotor.

5. Parameter configuration, hydraulic connection, wiring and

installation of amplifiers should be provided by machine tool

builders.

You can choose NIKKEN Controller when the machine

doesn’t have additional axis.

Note: at least one M-signal code is required.

1. At least one M-Signal is required on the machine.

2. Input M-signal as “index start” command on the machine, high

accuracy indexing, equally divided indexing (2-9999), or lead

operation is allowed.

3. Control unit, servo-motor and all cables will be supplied by

NIKKEN.

●5AX Rotary & Tilting Table

●Single Axis CNC Rotary Table

M-signal CTRL

21Controller

*5AX : Both Axis

*5AX : Each Axis

EZController

*Code No.

AA21

WAA21

DAA21

EZ

ROBODRILL -DSiB5 Series

ROBODRILL -DMiB5 Series

M-SIGNAL O/P ACC TEC NET

-DSiB5 -DMiB5

CNC Rotary Table for ROBODRILL

How to Select Your Best CNC Rotary Table

4th AXIS

(or 5th AXIS)

Z-axis

(Amplifier)

Y-axis

X-axis

Power &

Feed back cable

(Optional)

CNC Rotary Table

4th (or 5th) AXIS M/C

Nikken controller

M-signal cable

M-signal

(Amplifier)

CNC Rotary Table

Power &

Feed back cable

(Optional)

3th AXIS M/C

How to Read Product Code

1

2

NCT200

EL

F

A

-

M

Code No. of vertical/horizontal type CNC rotary table

CNC Rotary Table

NCT : Standerd

NCTZ : High Speed

Code No. of vertical/horizontal type CNC rotary table CNC : Standerd CNCZ : High Speed

Diameter of the rotary

table face plate (mm)

Diameter of the rotary table face plate (mm)

Motor mounting location

Non: Right mount, L: Left mount

Face Plate

W/O Face Plate : E

With Face Plate : No Letter

Motor maker

Type of motor Non: DC servo, A: AC servo

With/without Motor Non: without motor

M: with motor

CNC

*Code No.

Makers for Additional Axis CTRL

FANUC F

180

Motor maker (

*

Code No.)

Type of motor Non : DC servo, A: AC servo

With / without Motor Non : without motor M : with motor

FL A - M

NCT200

5AX- 201 F A - M

5AX-201

Code No. of Rotray & Tilting Table

Diameter of the table face plate (mm)

Type of motor Non: DC servo, A: AC servo

With/without Motor

Non: without motor, M: with motor

Motor maker

OP

ACC

TEC

NET

■SUPPORT TABLE

■TAILSTOCK

■SCROLL CHUCK

■POWER CHUCK

■Rotary Joint

■Type of Rotary Joint

■High Precise Indexing

■High Precise Indexing with Thru-hole

■Relation between Unbalancing Load

and Servo Motor

■

Flow Chart of the Additional Axis Control

■Notes on the Use of DD TABLES

■Accuracy Standard

■Technical Information

■WORLD WIDE SALES BRANCH

■Headguater

ACCESSORIES

・・・

P.15

M-

SIGNAL

■α21 and EZ controller feature

■α21 and EZ controller connection

■Input / Output Time Chart

■Connection for Automatic Operation

TECHNICAL

INFORMATION

・・・

P.17

WORLDWIDE

NETWORK

・・・・・・・P.21

CNC105LFA

CNC205LFA

5AX-100FA

5AX-DD100AF

CNC180LFA

CNC202LFA

CNC205LFA

CNC260LFA

NCT200LFA

NCT200ELFA

5AX-130FA

5AX-201FA

5AX-DD200AF2

5AX-DD200BF2

α-D14SiB5

/

α-D14SiB5ADV

α-D21SiB5

/

α-D21SiB5ADV

P. 3

α-D14MiB5 /

α-D14MiB5ADV

α-D21MiB5 /

α-D21MiB5ADV

α-D14LiB5

/

α-D14LiB5ADV

α-D21LiB5

/

α-D21LiB5ADV

P. 6

It is not exaggeration that the most important parts of the CNC rotary table is worm system. Please choose

NIKKEN CNC rotary table with special worm system for our anti-wearing, high rigidity and high speed rotation.

CNCZ202

(66.6min-1)

Bronze/

Aluminium Bronze

Worm Wheel

(

33.3min-

1

)

NIKKEN CNC Rotary Table

Useful Life3mon. 6mon. 12mon. 2yrs. 3yrs.

Adjustment of Backlash

Backlash(Amount of wearing)

Hardness of Worm Wheel

Depth 0.1mm

HV980

+αInside

HRC36

Worm Wheel of Others

(Bronze/Aluminium Bronze)

micron

ANTI-WEARING, HIGH RIGIDITY and HIGH SPEED ROTATION

■Worm Wheel

Specially hardened and

furthermore ion-nitrided on the

tooth. Thus, the problem of the

sliding friction is solved. The

hardness of the tooth surface and

inside is shown at right hand side.

Worldwide Field-proven

NIKKEN CNC Rotary Table

Worm Wheel

HV980+α

Steel Way

HRC58~60

Special Worm Screw

When mounting a CNC ROTARY TABLE on ROBODRILL, the machine needs an additional axis option.

(Servo amplifier, connector unit, etc.)

You need to be careful when using CNCROTARY tables in foreign countries. In the case of machines for Europe and

China, the connector unit is different from that for general use Please contact the machine specifications when ordering.

If you want to mount the tilt CNC rotary table on a machine that supports only one additional axis, or if you can not

prepare the additional axis, you can select with a NIKKEN controller.

NIKKEN

CONTROLLER

・・・ P.13

OPTIONAL

EQIPMENTS

・・・・・・

P.14

Motor mounting location Non: Right mount, L : Left mount, B: Back mount, T : Top mount

■ Additional Axis ■ NIKKEN Controller (M-signal)

How CNC Rotary Table is Controlled

You can choose additional axis when the machine has 4th

or 5th axis.

CNC rotary table can be controlled by machine in this case.

1. 4th or 5th amplifier is required for the machine. It should be

used exactly the same one used for X, Y and Z axis. Install

same servomotor(s) used for X, Y and Z axis.

2. The type of the servomotor or amplifier is defined by the types

of rotary table.

3. Decide by whom servomotor will be supplied.

4. External dimensions and specifications depend on the type of

servomotor.

5. Parameter configuration, hydraulic connection, wiring and

installation of amplifiers should be provided by machine tool

builders.

You can choose NIKKEN Controller when the machine

doesn’t have additional axis.

Note: at least one M-signal code is required.

1. At least one M-Signal is required on the machine.

2. Input M-signal as “index start” command on the machine, high

accuracy indexing, equally divided indexing (2-9999), or lead

operation is allowed.

3. Control unit, servo-motor and all cables will be supplied by

NIKKEN.

●5AX Rotary & Tilting Table

●Single Axis CNC Rotary Table

M-signal CTRL

21Controller

*5AX : Both Axis

*5AX : Each Axis

EZController

*Code No.

AA21

WAA21

DAA21

EZ

ROBODRILL -DSiB5 Series

ROBODRILL -DMiB5 Series

M-SIGNAL O/P ACC TEC NET

-DSiB5 -DMiB5

CNC Rotary Table for ROBODRILL

How to Select Your Best CNC Rotary Table

4th AXIS

(or 5th AXIS)

Z-axis

(Amplifier)

Y-axis

X-axis

Power &

Feed back cable

(Optional)

CNC Rotary Table

4th (or 5th) AXIS M/C

Nikken controller

M-signal cable

M-signal

(Amplifier)

CNC Rotary Table

Power &

Feed back cable

(Optional)

3th AXIS M/C

How to Read Product Code

1

2

( *1)The figures with orange color are the figures for(α-DSiB5ADV Series)

( *1)The figures with orange color are the figures for(α-DSiB5ADV Series)

300

300

285

(400*1)(80*1)

6301505 150 5

150

φ105

15045 140 135

105

150 150

315

375

330

93257

125125

330 150 155150200

150 13720 150 88

14h7

300

300

330150200 155150

125 125

14h7

(25)

350 123 150150 10780

257

350

93

105 93

198

165 15

φ105

150

88

14

170

140

112135

247

482441

14

220 13240

123350

473

630 150 51505

150 200155 150 330

125 125

14h7

287 150 13

20

280 35

330150

345135

150 150

150150

21015020 252 150 113

115

300

(140*1)

(140*1)

150150

115

300

(140*1)(165*1)

225

102 102

204

133.5192 118.5

11 214

φ90

5

224

462

135 150 177

150 200155 150 330

125 125

14h7

21015050 252 150 113

630 150 51505

287 150 13

20

280 35

345

150 150

80 400

135

( *1)The figures with green color are the figures for metal cover.

95

φ200

98

105

135 100

235

14

200

773

φ100

80

98 80 150 5

150630 55

(25)

150

1505

150150

φ200

160 320

150 330

452

(80*1) (400*1)

φ100

Please arrange the plate by customer

φ90

φ90

55135

CNC105LFA CNC205LFA(TAS-100N)

■CNC205LFA(TAS-100N)

■CNC105LFA

■5AX-100FA

■5AX-100FA

COMPACT CNC ROTARY TABLE

●Diameter of Table : φ105mm

●MAX. Work Load : 30kg

●

MAX. Rotation Speed

: 33.3(min-1),66.6(min-1)

*1

●Indexing Accuracy : ± 30sec.

●Brake Torque : 205N·m

●Net Weight : 30kg

●Servo Motor :αiF1/5000

●Spindle Hole : φ60mmH7×

φ30mm Through Hole

*1:High speed Z series

Slim type CNC ROTARY TABLE

●Diameter of Table : φ200mm

●MAX. Work Load : 100kg(with support table)

●

MAX. Rotation Speed

: 33.3(min-1),66.6(min-1)

*1

●Indexing Accuracy : ± 20sec.

●Brake Torque : 380N·m

●Net Weight : 45kg

●Servo Motor :αiF2/5000

●6 ports buit rotary joint can be fitted

*1:High speed Z series

Angle 5AX-100FA

0°

45°

0°

90°

0°

105°

■

The Area of Noninterference in Tilting Position.

φ170

φ140

40 15

φ170

φ140

40 15

φ180

φ150

φ140

40 45

15°

Extensive Lineup of Attachments

Jig Plate Scroll Chuck Center Socket

Compact 5AX TILTING ROTARY TABLE

●Diameter of Table : φ90mm

●MAX. Work Load : 20kg(Vertical)40kg(Horizontal)

●

MAX. Rotation Speed

:

44.4(min-1)(Rotary),22.2(min-1)(Tilting)

●Indexing Accuracy :

±30sec.(Rotary), 60sec.(Tilting)

●Brake Torque :

200N

·

m(Rotary), 410N

·

m(Tilting)

●Net Weight : 84kg

●Servo Motor :αiF1/5000

(

Rotary

)

αiF1/5000

(

Tilting

)

●Spindle Hole : φ50mmH7×

φ30mm Through Hole

●Tilting Angle : 0°~ 105°

5AX TILTING ROTARY TABLE for ROBODRILL -DSiB5

CNC ROTARY TABLE for ROBODRILL -DSiB5/ -DSiB5ADV

M-SIGNAL O/P ACC TEC NET

-DSiB5 -DMiB5

5AX TILTING ROTARY TABLE for ROBODRILL -DSiB5ADV

3

4

( *1)The figures with orange color are the figures for(α-DSiB5ADV Series)

( *1)The figures with orange color are the figures for(α-DSiB5ADV Series)

300

300

285

(400*1)(80*1)

6301505 150 5

150

φ105

15045 140 135

105

150 150

315

375

330

93257

125125

330 150 155150200

150 13720 150 88

14h7

300

300

330150200 155150

125 125

14h7

(25)

350 123 150150 10780

257

350

93

105 93

198

165 15

φ105

150

88

14

170

140

112135

247

482441

14

220 13240

123350

473

630 150 51505

150 200155 150 330

125 125

14h7

287 150 13

20

280 35

330150

345135

150 150

150150

21015020 252 150 113

115

300

(140*1)

(140*1)

150150

115

300

(140*1)(165*1)

225

102 102

204

133.5192 118.5

11 214

φ90

5

224

462

135 150 177

150 200155 150 330

125 125

14h7

21015050 252 150 113

630 150 51505

287 150 13

20

280 35

345

150 150

80 400

135

( *1)The figures with green color are the figures for metal cover.

95

φ200

98

105

135 100

235

14

200

773

φ100

80

98 80 150 5

150630 55

(25)

150

1505

150150

φ200

160 320

150 330

452

(80*1) (400*1)

φ100

Please arrange the plate by customer

φ90

φ90

55135

CNC105LFA CNC205LFA(TAS-100N)

■CNC205LFA(TAS-100N)

■CNC105LFA

■5AX-100FA

■5AX-100FA

COMPACT CNC ROTARY TABLE

●Diameter of Table : φ105mm

●MAX. Work Load : 30kg

●

MAX. Rotation Speed

: 33.3(min-1),66.6(min-1)

*1

●Indexing Accuracy : ± 30sec.

●Brake Torque : 205N·m

●Net Weight : 30kg

●Servo Motor :αiF1/5000

●Spindle Hole : φ60mmH7×

φ30mm Through Hole

*1:High speed Z series

Slim type CNC ROTARY TABLE

●Diameter of Table : φ200mm

●MAX. Work Load : 100kg(with support table)

●

MAX. Rotation Speed

: 33.3(min-1),66.6(min-1)

*1

●Indexing Accuracy : ± 20sec.

●Brake Torque : 380N·m

●Net Weight : 45kg

●Servo Motor :αiF2/5000

●6 ports buit rotary joint can be fitted

*1:High speed Z series

Angle 5AX-100FA

0°

45°

0°

90°

0°

105°

■

The Area of Noninterference in Tilting Position.

φ170

φ140

40 15

φ170

φ140

40 15

φ180

φ150

φ140

40 45

15°

Extensive Lineup of Attachments

Jig Plate Scroll Chuck Center Socket

Compact 5AX TILTING ROTARY TABLE

●Diameter of Table : φ90mm

●MAX. Work Load : 20kg(Vertical)40kg(Horizontal)

●

MAX. Rotation Speed

:

44.4(min-1)(Rotary),22.2(min-1)(Tilting)

●Indexing Accuracy :

±30sec.(Rotary), 60sec.(Tilting)

●Brake Torque :

200N

·

m(Rotary), 410N

·

m(Tilting)

●Net Weight : 84kg

●Servo Motor :αiF1/5000

(

Rotary

)

αiF1/5000

(

Tilting

)

●Spindle Hole : φ50mmH7×

φ30mm Through Hole

●Tilting Angle : 0°~ 105°

5AX TILTING ROTARY TABLE for ROBODRILL -DSiB5

CNC ROTARY TABLE for ROBODRILL -DSiB5/ -DSiB5ADV

M-SIGNAL O/P ACC TEC NET

-DSiB5 -DMiB5

5AX TILTING ROTARY TABLE for ROBODRILL -DSiB5ADV

3

4

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

1

/

24

100%