Clean rooms in the food sector are dependent on

stainless steel

Clean rooms in the food sector - also known as sterile rooms - depend heavily on stainless steel

equipment and also on duplex stainless steel suppliers. They have to contain as few particles

as possible and prevent contamination during production, the assembly and testing phase.

Hygienic properties of alloy steel fittings and astm a790 s32205 are essential for conveyor

systems for meat processing as an example for clean rooms in the food sector.

Why stainless steel for clean rooms in the food sector?

Stainless steel offers solutions for equipment, and for machines and for this they depend on

duplex pipe manufacturer. It guarantees minimal particle generation compared to other

materials. Clean rooms in the food sector also benefit from this, because they have to meet

strict industrial or regulatory requirements. One of the critical properties of stainless steel astm

a276 uns s31803 is its resistance to damage during sanitization.

Any surface roughness or damage can, therefore cause microscopic holes and edges. This also

applies if harsh chemicals and bleaches are used. It is always important to take care of uns

s31803 pipe devices efficiently and without damage. This should be subject to certain

regulations because the use of wrong methods also leads to corrosion.

Stainless steel, clean rooms and food processing

Stainless Steel uns s32760 pipe is widely used in the beverage and food industries and the

super duplex pipe suppliers ensure about quality. In general, it is not only used in processing

and production, but also in warehousing, in the transport industry as well as in preparation and

demonstration. Polished stainless steel of duplex 2205 sheet is the first choice in the production

of components and equipment for food processing. It is a constantly growing branch within the

food industry. Due to the constantly increasing demand for ready meals, for example, the

production of cold cuts contributes to the promotion and growth of the meat industry.

Corrosion-resistant materials

It’s resistance to acids is particularly important when dealing with astm a789 tubing. In

addition, to clean rooms in the food sector and use in marine environments, 1.4404 is also

found in components of industrial ovens, engine parts, boilers and evaporators.

European regulations for planning with stainless steel

Most containers, pipes and food tools are made of austenitic grades 1.4301 or 1.4404 as assured

by duplex tube suppliers. They describe the use of stainless steel astm a276 uns s32760. Both

grades meet the requirements.

Stainless steel type 1.4404 is mostly used in the food industry. Material 1.4404 is also known

as "food grade." It is mostly used with increasingly corrosive foods. These are, for example,

those with a higher salt content such as meat. The steadily growing consumption of meat is

also causing an increase in industrial meat processing. This, in turn, means that improved and

more concentrated cleaning measures must be used to prevent harmful bacterial contamination.

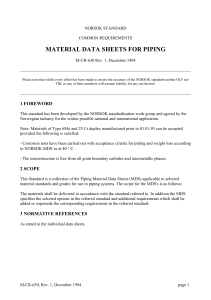

Widespread and recommended cleaning methods for stainless steel in the food industry are:

• Water and steam

• mechanical chafing

• Washing-up powder and detergent

• alkaline solutions

• organic solvents

• nitric acid

Of course, the rules of the manufacturing institutions of duplex 2205 round bar, as well as the

advice of the device manufacturers, must be strictly followed. This leads to the prevention of

food poisoning as well as the deterioration of steel products.

1

/

2

100%