Algorithms for On-board Battery Management System in Electric Vehicle for State of

Charge Estimation and Dynamic Voltage Simulation of Lithium-ion Batteries (LIB):

Considering Cell Aging

Kamyar Makinejad, Amin Sakka, Andreas Jossen*, Wen Changyun**

TUM CREATE, Singapore, kamyar.makin[email protected]

* Technische Universität München (TUM), Institute for Electrical Energy Storage Systems (EES), Munich, Germany

** Nanyang Technological University (NTU), school of electrical & electronic engineering, Singapore, [email protected]

1. Introduction

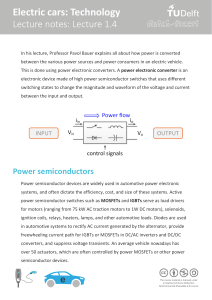

Battery management system (BMS) is an on-board integrated part for an electric

vehicle (EV) and must perform certain tasks in real time to provide high storage

utilization, long lifetime and safe operation. Biggest challenge in BMS, is accurate

battery state estimation. This work focuses on algorithms with functions of

estimating these states such as state of charge (SOC), state of health (SOH) and

additionally, functions to calculate cell/pack voltage and to estimate required

resistances and capacitances for further processes. Aside from the slight

differences in manufacturing process of the commercial cells, some cells within

the battery pack can be exposed to elevated temperatures based on their location,

different mechanical stresses such as compression or vibrations and many other

factors which affect their performance like loose connections and wirings. All

these will eventually lead to inhomogeneity among the cells and brings different

aging levels and SOC variations between them. Therefore in this work we suggest

an algorithm for SOC estimation that takes cell to cell inhomogeneity and aging

into account

2. Experimental

Test setup includes high capacity battery cyclers (up to 1200A), Temperature chambers (600L Temperature and humidity control), fast

data acquisition systems, hardware in the loop system (HIL) and electrochemical impedance spectroscopy (EIS) meters among others.

High power pouch LIBs with NMC technology are used for the experiments, these are same cells used in the EVA battery pack, an

electric taxi developed for Singapore [1]. Reference performance tests (RPT) as well as drive cycle tests were performed on single

cell; modules and the battery pack itself. To study the temperature and aging effects on cell performance and monitoring algorithms,

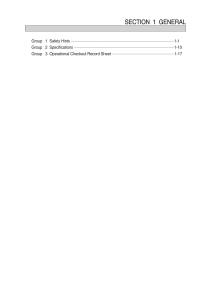

Cells underwent accelerated aging tests at various temperatures as shown in figure 1. For each test plan, three cells are used to achieve

statistically reliable results. After every 100 cycles (cycle life aging), EIS and Hybrid pulse power Characterization (HPPC) and drive

cycle tests as part of RPT tests were repeated on the cells until cell’s end of life (EOL).

3. Results and Discussion

From the experimental, test data were used to develop real time up-scalable equivalent circuit model (ECM) simulating driving cycle

as shown in figure 2. ECM models are studied at [2] to create voltage simulation model for single cell. Additionally algorithms were

developed and adopted to estimate state SOC and SOH of the individual cells within the battery pack by EKF to evaluate the pack

performance since the SOC/capacity of the pack is influenced by the lowest SOC/capacity of the cell within the pack. The work is

developed in offline mode and evaluated in real time with HIL setup. After evaluation of the models and algorithms, the code is

optimizes to use for in house developed BMS. Algorithms are proven to be stable, fast convergence and low cost efficient.

Figure 2. (A) Battery pack voltage model from up scaled cell voltage model, (B) total SOC of the battery pack vs weakest cell Test at 25˚C on new battery pack

References

[1] “EVA by TUM CREATE – Electric Taxi for Tropical Megacities: Home.” [Online]. Available: http://www.eva-taxi.sg/.

[2] J. Jamnik and J. Maier, “Generalised equivalent circuits for mass and charge transport: chemical capacitance and its

implications,” Phys. Chem. Chem. Phys., vol. 3, no. 9, pp. 1668–1678, 2001.

Start of the test

RPT test at 25˚C

Cycling at 15/25/40/50/60/˚C for 100

cycles

RPT test at 25˚C

Cell capacity<80% initial capacity

End of Test (Cell EOL)

Yes

No

1c charge/

discharge

Figure 1. Aging test flowchart used in this work

1

/

1

100%