Chemical Engineering Problem Set: Conversions & Stoichiometry

Telechargé par

kpaulous

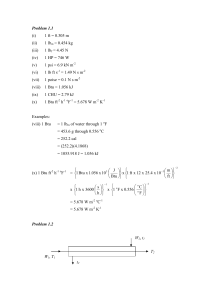

Problem 1.1

(i) 1 ft = 0.305 m

(ii) 1 lbm = 0.454 kg

(iii) 1 lbf = 4.45 N

(iv) 1 HP = 746 W

(v) 1 psi = 6.9 kN m-2

(vi) 1 lb ft s-1 = 1.49 N s m-2

(vii) 1 poise = 0.1 N s m-2

(viii) 1 Btu = 1.056 kJ

(ix) 1 CHU = 2.79 kJ

(x) 1 Btu ft-2 h-1 oF-1 = 5.678 W m-2 K-1

Examples:

(viii) 1 Btu = 1 lbm of water through 1 oF

= 453.6 g through 0.556 oC

= 252.2 cal

= (252.2)(4.1868)

= 1055.918 J = 1.056 kJ

(x) 1 Btu ft-2 h-1 oF-1 = ⎭

⎬

⎫

⎩

⎨

⎧⎟

⎠

⎞

⎜

⎝

⎛

Btu

J

10 x 1.056Btu x 1 3x

2

3ft

m

10x25.4x12xft1

−

−

⎭

⎬

⎫

⎩

⎨

⎧⎟

⎠

⎞

⎜

⎝

⎛

x

1

h

s

3600xh1

−

⎭

⎬

⎫

⎩

⎨

⎧⎟

⎠

⎞

⎜

⎝

⎛x

1

o

o

oF

C

0.556xF1

−

⎭

⎬

⎫

⎩

⎨

⎧

⎟

⎟

⎠

⎞

⎜

⎜

⎝

⎛

= 5.678 W m-2 oC-1

= 5.678 W m-2 K-1

Problem 1.2

W1, T1t2

W2, t1

T2

Variables, M:

1. Duty, heat transferred, Q

2. Exchanger area, A

3. Overall coefficient, U

4. Hot-side flow-rate, W1

5. Cold-side flow-rate, W2

6. Hot-side inlet temperature, T1

7. Hot-side outlet temperature, T2

8. Cold-side inlet temperature, t1

9. Cold-side outlet temperature, t2

Total variables = 9

Design relationships, N:

1. General equation for heat transfer across a surface

Q = UAΔTm (Equation 12.1)

Where ΔTm is the LMTD given by equation (12.4)

2. Hot stream heat capacity

(

)

211 TTCWQ p

−

=

3. Cold stream heat capacity

(

)

122 ttCWQ p

−

=

4. U is a function of the stream flow-rates and temperatures (see Chapter 12)

Total design relationships = 4

So, degrees of freedom = M – N = 9 – 4 = 5

Problem 1.3

Number of components, C = 3

Degrees of freedom for a process stream = C + 2 (see Page 17)

Variables:

Streams 4(C + 2)

Separator pressure 1

Separator temperature 1

Total 4C + 10

Relationships:

Material balances C

v-l-e relationships C

l-l-e relationships C

Equilibrium relationships 6

Total 3C + 6

Degrees of freedom = (4C + 10) – (3C + 6) = C + 4

For C = 3, degrees of freedom = 7

The feed stream conditions are fixed which fixes C + 2 variables and so the design

variables to be decided = 7 – 5 = 2.

Choose temperature and pressure.

Note: temperature and pressure taken as the same for all streams.

Problem 1.4

l

h

l

Volume = l 2 x h = 8 m3

(i) Open Top

Area of plate =

lhl 4

2+

=

22 8x4 −

+lll

Objective function =

12 32 −

+ll

Differentiate and equate to zero:

2

320 −

−= ll

m52.216

3==l i.e. 2

l

h=

(ii) Closed Top

The minimum area will obviusly be given by a cube, l = h

Proof:

Area of plate =

lhl 42 2+

Objective function =

12 322 −

+ll

Differentiate and equate to zero:

2

340 −

−= ll

38=l = 2 m

2

2

8

=h= 2 m

Problems 1.5 and 1.6

Insulation problem, spread-sheet solution

All calculations are peformed per m2 area

Heat loss = (U)(temp. diff.)(sec. in a year)

Savings = (heat saved)(cost of fuel)

Insulation Costs = (thickness)(cost per cu. m)(capital charge)

Thickness U Heat Loss Increment Extra Cost

(mm) (Wm-2C-1) (MJ) Savings (£) Insulation (£)

0 2.00 345.60 20.74

25 0.90 155.52 11.40 0.26

50 0.70 120.96 2.07 0.26

100 0.30 51.84 4.15 0.53 (Optimum)

150 0.25 43.20 0.52 0.53

200 0.20 34.56 0.52 0.53

250 0.15 25.92 0.52 0.53

Data: cost of fuel 0.6p/MJ

av. temp. diff. 10oC

200 heating days per year

cost of insulation £70/m3

capital charges 15% per year

American version:

Thickness U Heat Loss Increment Extra Cost

(mm) (Wm-2C-1) (MJ/yr) Savings ($/m2) Insulation ($/m2)

0 2.00 518.40 45.66

25 0.90 233.28 25.66 0.6

50 0.70 181.44 4.66 0.6

100 0.30 77.76 9.33 1.2 (Optimum)

150 0.25 64.80 1.17 1.2

200 0.20 51.84 1.17 1.2

250 0.15 38.88 1.17 1.2

Data: cost of fuel 0.6 cents/MJ

av. temp. diff. 12oC

250 heating days per year

cost of insulation $120/m3

capital charges 20% per year

Problem 1.7

The optimum shape will be that having the lowest surface to volume ratio.

A sphere would be impractical to live in an so a hemisphere would be used.

The Inuit build their snow igloos in a roughly hemispherical shape.

Another factor that determines the shape of an igloo is the method of construction.

Any cross-section is in the shape of an arch; the optimum shape to use for a material

that is weak in tension but strong in compression.

Problem 1.8

1. THE NEED

Define the objective:

a) purging with inert gas, as requested by the Chief Engineer

b) safety on shut down

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

32

33

33

34

34

35

35

36

36

37

37

38

38

39

39

40

40

41

41

42

42

43

43

44

44

45

45

46

46

47

47

48

48

49

49

50

50

51

51

52

52

53

53

54

54

55

55

56

56

57

57

58

58

59

59

60

60

61

61

62

62

63

63

64

64

65

65

66

66

67

67

68

68

69

69

70

70

71

71

72

72

73

73

74

74

75

75

76

76

77

77

78

78

79

79

80

80

81

81

82

82

83

83

84

84

85

85

86

86

87

87

88

88

89

89

90

90

91

91

92

92

93

93

94

94

95

95

96

96

97

97

1

/

97

100%