Low-Cost PV System Controller Using Arduino and INC Algorithm

Telechargé par

Otman Oussalem

Our reference: MATPR 9999 P-authorquery-v14

AUTHOR QUERY FORM

Journal: MATPR

Article Number: 9999

Please e-mail your responses and any corrections to:

E-mail: [email protected].in

Dear Author,

Please check your proof carefully and mark all corrections at the appropriate place in the proof. It is crucial that you NOT make direct edits to

the PDF using the editing tools as doing so could lead us to overlook your desired changes. Rather, please request corrections by using the

tools in the Comment pane to annotate the PDF and call out the changes you would like to see. To ensure fast publication of your paper please

return your corrections within 48 hours.

For correction or revision of any artwork, please consult http://www.elsevier.com/artworkinstructions.

Any queries or remarks that have arisen during the processing of your manuscript are listed below and highlighted by flags in the proof.

Location in

article

Query / Remark: Click on the Q link to find the querys location in text

Please insert your reply or correction at the corresponding line in the proof

Q1 Your article is registered and is being processed for inclusion in a Special issue ``ICPEM 2019". For Any

deviations, please contact the Journal Manager at matpr@elsevier.com immediately before submitting the proof

corrections.

Q2 The author names have been tagged as given names and surnames (surnames are highlighted in teal color).

Please confirm if they have been identified correctly.

Q3 Please confirm that the provided email oussalem.otman@gmail.com is the correct address for official

communication, else provide an alternate e-mail address to replace the existing one, because private e-mail

addresses should not be used in articles as the address for communication.

Q4 Please note that as per standard style, a corresponding author footnote be provided for at least one author. Please

check and assign the corresponding author name.

Q5 Please check whether the designated corresponding author is correct, and amend if necessary.

Q6 Uncited references: This section comprises references that occur in the reference list but not in the body of the

text. Please cite each reference in the text or, alternatively, delete it. Any reference not dealt with will be

retained in this section.

Q7 Correctly acknowledging the primary funders and grant IDs of your research is important to ensure compliance

with funder policies. We could not find any acknowledgement of funding sources in your text. Is this correct?

Thank you for your assistance.

Please check this box or indicate

your approval if you have no

corrections to make to the PDF file

1

3A low cost controller of PV system based on Arduino board and INC

4algorithm

5

6

7O. Oussalem

⇑

,M. Kourchi,A. Rachdy,M. Ajaamoum,H. Idadoub,S. Jenkal

8LASIME (Engineering Science and Energy Management Laboratory) ENSA, Agadir, Morocco

9

11

article info

12 Article history:

13 Received 4 June 2019

14 Received in revised form 20 July 2019

15 Accepted 24 July 2019

16 Available online xxxx

17 Keywords:

18 PV

19 MPPT

20 Arduino

21 Incremental conductance (INC)

22 Matlab-Simulink

23

24

abstract

25

Photovoltaic (PV) systems offer a very competitive solution as an alternative energy source, but they have

26

a low efficiency. To overcome the problem of solar panel performance and achieve maximum efficiency, it

27

is necessary to optimize the design of all parts of the PV photovoltaic chain. Then we insert a stage of

28

adaptation between the photovoltaic generator (GPV) and the load. This stage which is controlled by a

29

microcontroller, will allow the system to search and reach the maximum power point (MPP). This algo-

30

rithm is among of other ones which are widely used in PV systems for their easy implementation as well

31

as their low cost. This algorithm was analyzed and its performance was evaluated by using the Arduino

32

board via Matlab-Simulink tool.

33

Ó2019 Elsevier Ltd. All rights reserved.

34

Selection and peer-review under responsibility of the scientific committee of the International

35

Conference on Plasma and Energy Materials ICPEM2019.

36

37

38

39

1. Introduction

40

In line with, its energy strategy which aims to achieve energy

41

independence, Morocco has accorded high priority to convert to

42

the renewable energies and especially solar thermal and photo-

43

voltaic energy [1].

44

Photovoltaic energy is a solution for the production of renew-

45

able energy based on a photovoltaic generator (GPV) from the solar

46

flux. In its operation a GPV has non-linear characteristics, which

47

depend among other things on the illumination, the temperature

48

of the cell and also on the characteristics of the charge. An adaptive

49

stage is inserted between the GPV and the load. This stage allows

50

driving the system to the maximum power point (MPP).

51

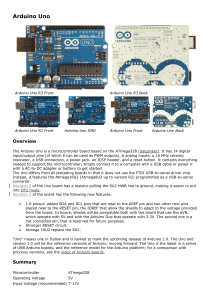

The aim of this work is the design and realization for the control

52

of different parties of a photovoltaic system by low cost board

53

(Arduino board) via the Matlab-Simulink software. The PV system

54

is customized by an ‘‘incremental” strategy which is a type of MPPT

55

algorithms that will ensure the achievement of the maximum

56

power provided by the PV module [2,3].

57

Various results are presented in this article in order to validate

58

this control platform as being the most cost-effective and efficient

59

for the optimization of the photovoltaic chain.

60

This article is divided into five parts: After the introduction, the

61

second part gives a general description of a photovoltaic system.

62

The third part deals with the interface based on the Arduino board

63

under the Matlab-Simulink environment. The fourth one will be

64

dedicated to the experimental results of the system studied.

65

Finally, this study finishes with a conclusion.

66

2. Photovoltaic system

67

The photovoltaic system under study consists of four blocks as

68

shown in Fig. 1. The first block represents the photovoltaic emula-

69

tor, the second block is the static converter DC-DC Buck-Boost, the

70

third block represents the DC load and the fourth one is the system

71

controller.

72

2.1. PV emulator

73

The PV panels are depends on climatic conditions, that’s why

74

we chose to employ a PV emulator.

75

This PV emulator is an electronic power system able to repro-

76

duce the characteristics of the solar panel, and which has the fol-

77

lowing characteristics [4]:

78

It consists of three independent blocks emulating solar panels;

79

Voltage of open circuit is 20 V;

80

Short-circuit current up to 2 A;

https://doi.org/10.1016/j.matpr.2019.07.689

2214-7853/Ó2019 Elsevier Ltd. All rights reserved.

Selection and peer-review under responsibility of the scientific committee of the International Conference on Plasma and Energy Materials ICPEM2019.

⇑

Corresponding author.

E-mail address: [email protected] (O. Oussalem).

Q5

Q1

Q2

Q3

Materials Today: Proceedings xxx (xxxx) xxx

Contents lists available at ScienceDirect

Materials Today: Proceedings

journal homepage: www.elsevier.com/locate/matpr

MATPR 9999 No. of Pages 7, Model 5G

8 August 2019

Please cite this article as: O. Oussalem,M.Kourchi,A.Rachdy et al., A low cost controller of PV system based on Arduino board and INC algorithm, Materials

Today: Proceedings, https://doi.org/10.1016/j.matpr.2019.07.689

81

Displays voltage and current variables on integrated displays for

82

each of the three blocks;

83

Simulation adjustable intensities of solar irradiation, each of the

84

three blocks.

85

86

For an irradiation of 400 W/m

2

, the characteristics (I–V) and (P–

87

V) of the photovoltaic emulator are illustrated in Figs. 2 and 3.

88

2.2. Static converter

89

The main role of the Buck-Boost power converter is to ensure

90

impedance matching, so that the output of the PV emulator deliv-

91

ers the maximum energy.

92

The electronic circuit corresponding to the Buck-Boost realized

93

(Fig. 4), is essentially based around the power MOSFET transistor,

94

type IRF730, driven by the Arduino control board via a driver, as

95

well as a diode, and passive components (L, C) ensuring the

96

smoothing and filtering of the current electric [5].

97

The main variables characterizing the Buck-Boost converter

98

[5,6] are:

99

The output voltage is :V

s

¼

a

1

a

V

e

ð1Þ

101101

102

The output current is :I

s

¼1

a

a

I

e

ð2Þ

104104

105

The current ripple :

D

I

L

¼

a

V

e

Lf ð3Þ

107107

108

The voltage ripple :

D

V

C

¼

a

I

s

Cf ¼

a

2

V

e

ð1

a

ÞRCf ð4Þ

110110

111

With:

112

a

: The duty cycle of the PWM signal or PWM.

113

f: The frequency of the PWM signal.

114

V

C

: voltage across the capacitor.

115

I

L

: current through the coil.

116

R: resistive load.

117

L and C: inductor and capacitor constituting the filter. The filter

118

values are: L 0.9 mH and C 27 mF.

119

120

2.3. PWM generator

121

There are a lot of generators of PWM signal, the used one is

122

based on the TL494 component. This is an integrated circuit of

123

pulse width modulation control for fixed frequency signals. The

124

circuit accompanying the TL494 component is described in the

125

electrical schema of Fig. 5 [7].

126

This generator can operate at frequencies up to 400 kHz.

127

According to technical documents of TL494 builder, the approxi-

128

mate oscillation frequency is determined by [7]:

129

f

c

¼1:1

R

t

C

t

ð5Þ

131131

Fig. 1. Schematic diagram of PV system with MPPT.

Fig. 2. The characteristic P (V) of the PV emulator for G = 400 W/m

2

.

Fig. 3. The characteristic I (V) of the PV emulator for G = 400 w/m

2

.

Fig. 4. Circuit of Buck-Boost converter.

2O. Oussalem et al. / Materials Today: Proceedings xxx (xxxx) xxx

MATPR 9999 No. of Pages 7, Model 5G

8 August 2019

Please cite this article as: O. Oussalem,M.Kourchi,A.Rachdy et al., A low cost controller of PV system based on Arduino board and INC algorithm, Materials

Today: Proceedings, https://doi.org/10.1016/j.matpr.2019.07.689

132

The duty cycle of the PWM signal is controlled by a voltage that

133

varies from 0 V to 2.5 V. The Mosfet used must be controlled by a

134

PWM signal greater than 7 V, for that reason, a driver was realized

135

for amplifying the signal of the PWM generator.

136

To follow the MPP, the platform needs two sensors: current and

137

voltage sensor. The voltage measurement is performed from a volt-

138

age divider to have a voltage between 0 and 5 V. The output of this

139

divider drives a follower amplifier realized by the circuit ‘‘LM324”

140

to the impedance matching. However the current measurement is

141

done by a shunt resistor of 1

X

.

142

3. MPPT strategy and support package for Arduino board

143

The strategy of maximizing the power from a photovoltaic

144

source is to seek the optimum operating point. This technique is

145

called: the MPPT strategy.

146

There are several types of MPPT strategies, among which is the

147

incremental conductance (INC) command, which this technique is

148

based on the knowledge of the GPV Conductor Variation and Posi-

149

tion Consequences operation in relation to a MPP [8].

150

Fig. 6 shows that the maximum power can then be tracked

151

by making comparisons to each moment of the value of the con-

152

ductance (Ipv/Vpv) with that of the increment ofConductance

153

(

D

Ipv/

D

Vpv). Vr corresponds to the reference voltage and forces

154

the GPV to operate at this value. If you are at the PPM, then the

155

voltage Vr corresponds well to the optimum voltage Vopt. Once

156

the PPM is reached, the operation can be maintained on this

157

position until a variation of

D

Ipv. This then indicates a change

158

in climatic conditions, so a new MPCs search. For this, the algo-

159

rithm increments or decrements the value of Vr up to reach the

160

MPP [9].

161

Matlab (Matrix laboratory) is a fourth-generation programming

162

language, developed by MathWorks. Matlab has provided a tool

163

books for Arduino called the support package, which includes a

164

Simulink block library to configure and access the sensors, actua-

165

tors and Arduino communication interfaces [2,3].

Fig. 5. PWM generator based on the TL494 circuit.

Fig. 6. Conventional flow chart of the MPPT control type ‘incremental conductance’.

O. Oussalem et al. / Materials Today: Proceedings xxx (xxxx) xxx 3

MATPR 9999 No. of Pages 7, Model 5G

8 August 2019

Please cite this article as: O. Oussalem,M.Kourchi,A.Rachdy et al., A low cost controller of PV system based on Arduino board and INC algorithm, Materials

Today: Proceedings, https://doi.org/10.1016/j.matpr.2019.07.689

166

This developed configuration (Fig. 7) is for the treaty system,

167

based on the Simulink environment.

168

4. Experimental result

169

The experimental realization of the photovoltaic system under

170

study, as shown in the Fig. 8, is composed of a PV emulator, a

171

Buck-Boost chopper, sensors of Ipv (PV emulator current) and

172

Vpv (PV emulator voltage), a resistive load, and an Arduino Mega

173

board.

174

The experimental test of the studied system should start by

175

attacking the Arduino board, by the program of the ‘incremental

176

conductance’ strategy treated previously.

177

It is noted that during the experimental process, some adapta-

178

tions and calibrations were made between the various variables

179

treated in the photovoltaic system. Thus the system can search

180

for and converge towards the point of maximum power.

181

The PV emulator offers the possibility to choose the G value of

182

the irradiation by selecting one of the two values 400 and

183

600 W/m

2

, in order to see the influence of the ‘incremental conduc-

184

tance’ strategy on the PV emulator’s output power (Ppv).

185

Fig. 9 describes the evolution of the PV emulator’s output power

186

for the irradiation G = 400 W/m

2

.

187

Those figures illustrate the curves of the PV emulator’s output

188

power Ppv as a function of the time and of the voltage Vpv. These

189

curves are processed in order to show that the photovoltaic system

190

realized was able to seek and follow the power supplied and to

191

reach the output power around the maximum power point (MPP)

192

at around 13 W for an irradiation of G = 400 w/m

2

.

193

It is also remarkable in Fig. 10, that the system following its

194

curves of the PV emulator’s output power in function of the voltage

195

and of the time, behaves by the same way in a second test for irra-

196

diation G = 600 w/m

2

. So it was able to reach the output power

197

around its new maximum power point (around of 16 W).

Fig. 7. Control Simulink interface.

Fig. 8. The parts of the designed PV chain.

4O. Oussalem et al. / Materials Today: Proceedings xxx (xxxx) xxx

MATPR 9999 No. of Pages 7, Model 5G

8 August 2019

Please cite this article as: O. Oussalem,M.Kourchi,A.Rachdy et al., A low cost controller of PV system based on Arduino board and INC algorithm, Materials

Today: Proceedings, https://doi.org/10.1016/j.matpr.2019.07.689

6

6

7

7

1

/

7

100%