ا

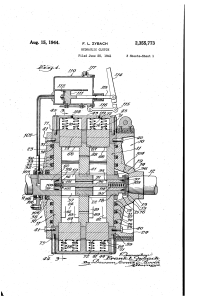

Hydraulic Power (pumps)

Definition of Hydraulic Pumps

•The mechanical device that is used to convert mechanical

power into hydraulic energy is known as a hydraulic pump.

The load that is responsible for the pressure is overcome

with this device by creating sufficient power and

generating a flow.

•The hydraulic pump has two functions to perform during

operation, allowing atmospheric pressure to push liquid

into the inlet line from the reservoir to the pump by the

mechanical action created vacuum at the pump. The other

function it performs is that the pumps mechanical action

supplies the liquid to the pump outlet and then forced into

the hydraulic system.

Types of hydraulic pumps

Gear pumps Vane pumps Piston pumps

The operation of the vane pump is based on , the rotor which contain

radial slots rotate by a shaft and rotate in cam ring (housing), each

slot contain a vane design as to comes out from the slot as the rotor

turns. During one half of the rotation the oil inters between the vane

and the housing then this area starts to decrease in the second half

which permit the pressure to be produced , then the oil comes out

pressurizes to the output port.

Types of vane pump

1- Fixed Displacement vane pump

2- Variable Displacement vane pump

Vane pumps

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

21

21

22

22

23

23

24

24

25

25

26

26

27

27

28

28

29

29

30

30

31

31

32

32

33

33

34

34

35

35

1

/

35

100%